Description

Crosby manufactures a variety of turnbuckle assemblies that are offered in some combinations that include Eye and Eye, Hook and Hook, Hook and Eye, Jaw and Jaw, and Jaw and Eye. Every end fitting on Crosby turnbuckles are Quenched, and Tempered or Normalized and the bodies are heat treated by normalizing. The benefits offered from the quenching and tempering is that the impact properties are enhanced for improved strength at all temperatures. Crosby turnbuckles are meant for straight or in-line pulling only.

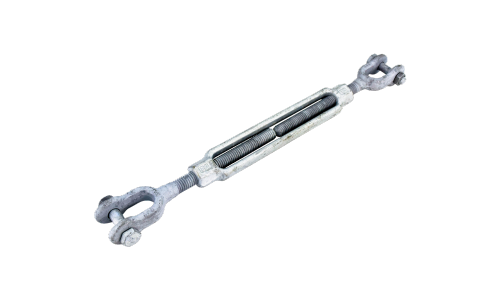

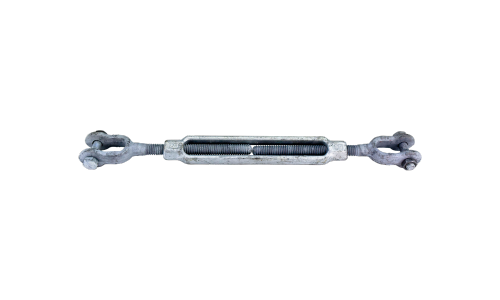

The Crosby HG-228 Jaw and Jaw Turnbuckles are made from hot-dip galvanized steel. They have forged Jaw ends that are equipped with nuts and bolts for sizes ¼”-⅝”, and then they use pins and cotters in sizes ¾”-2¾”.

A turnbuckle, stretching screw or bottlescrew is a device for adjusting the tension or length of ropes, cables, tie rods, and other tensioning systems. It normally consists of two threaded eye bolts, one screwed into each end of a small metal frame, one with a left-hand thread and the other with a right-hand thread. The tension can be adjusted by rotating the frame, which causes both eye bolts to be screwed in or out simultaneously, without twisting the eye bolts or attached cables.

Crosby turnbuckles are most commonly used in applications which require a great deal of tension; they can range in mass from about ten grams for thin cable used in a garden fence, to thousands of kilograms for structural elements in buildings and suspension bridges.

Crosby turnbuckles come in various sizes and are popularly used in construction. They combine strength and durability, yet are simple to set up and adjust. Very small Crosby turnbuckles (as light as 10 grams) might be used to support a fence in a garden. On the other hand, extremely large Crosby turnbuckles (as heavy as several kilograms) are widely used as support high-rise buildings or in structures such as bridges.

Crosby turnbuckles have been used in aircraft construction. Historically, biplanes might use Crosby turnbuckles to adjust the tension on structural wires bracing their wings. Crosby turnbuckles are also widely used on flexible cables in flight control systems. In both cases they are secured with lockwire or specifically designed wire rope clips to prevent them from turning and losing tension due to vibration.

Crosby turnbuckles are used for tensioning a ship’s rigging and lashings. This device is also known as a bottlescrew in this context.

Crosby turnbuckles find common use to tension the ropes in professional wrestling rings and boxing rings, where they serve as the attachment between the ring ropes and ring posts. Rather than the usual bare metal, here the Crosby turnbuckles are covered with padding in order to protect participants and staff. Crosby turnbuckles even play a part in professional wrestling where they are often dramatically used by participants as part of their offensive repertoire.

Crosby turnbuckles are used in nearly all rigging performed in the entertainment industry, including theatre, film, and live concert performances. In entertainment rigging, Crosby turnbuckles are more commonly used to make small adjustments in line lengths. This is generally to make a flown unit sit parallel to the stage. Another way a Crosby turnbuckle could prove helpful is with making very minor height or angle adjustments.

Crosby turnbuckles are used in piping systems as a way to provide minor adjustments for field inconsistencies. This also allows for a minimum amount of resistance when transferring the load to the support components.