Description

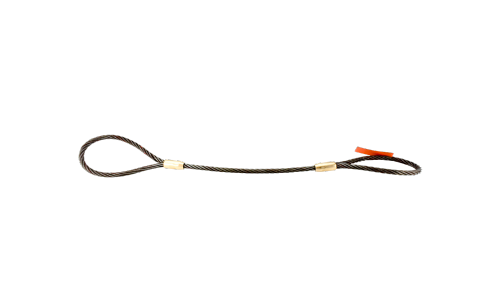

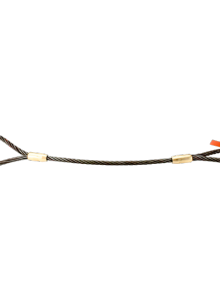

Tway 5/8″ Eye & Eye Wire Rope Slings

Tway Lifting Products manufactures eye & eye wire rope slings, spreaders and assemblies from ¼”-2”. We stock fittings and components that allow us to produce a full range of wire rope slings multi-leg assemblies, crane boom support cables, and bridge crane hoist ropes.

Our in-house proof testing center is used to verify the integrity of the products we manufacture. Every wire rope sling or bridle that we produce includes an OSHA appropriate DuraTag stating: size, working load limit, number of legs, and angle chart graphics. Our assemblies are manufactured to the highest standards by trained professionals. All of our wire rope slings are made from USA made products. The most common wire rope sling type is the eye and eye single leg.

Eye & Eye Wire Rope Slings are extremely strong and an excellent choice for heavy duty jobs involving not only lifting, but also hoisting, towing, or anchoring loads. The fabrication of wire slings also offers excellent abrasion-resistance and heat resistance so it can be used in extreme conditions and temperatures. Its pliable design can conform to the shape of a load for a more secure application.

Eye & Eye Wire Rope Slings are manufactured in a variety of configurations, with 6×19 and 6×36, being two of the most common. The numbers represent the number of wires making up the strand and the number of strands wrapped around the core. For example, a 6×19 indicates that there are 19 wires making up a strand, and 6 strands are wrapped around the core.

Each steel wire rope configuration will offer different benefits and will be better suited to certain applications. In general, a smaller number of large outer wires offers better wear and corrosion resistance, while a larger number of small wires provides a better level of flexibility and fatigue resistance.

We offer steel wire rope slings in both 6×19 and 6×36 configurations, depending on the diameter of the wire rope. All are in a bright (unfinished) wire rope, but other configurations are available by request. Our cable laid slings are manufactured in a 7x7x7 galvanized wire rope (composed of 7 strands of 7×7 cables), which make them extremely flexible and useful for more specialized applications.

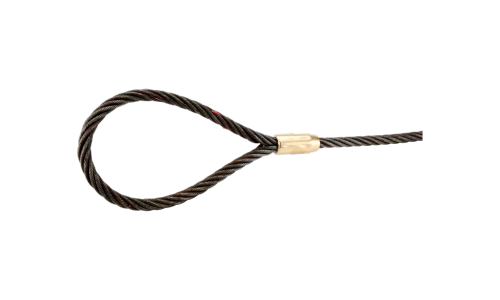

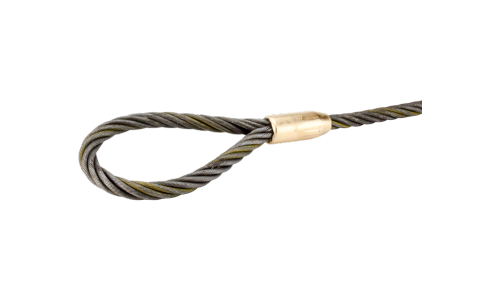

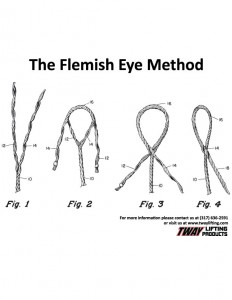

The eye loops on our sling cable are created with a flemish splice, which is a mechanical splice where the rope cable is separated into two parts (one part has three strands, the other part has the remaining three strands plus the core), then re-laid back in the opposite direction to form the loop. The ends are then secured with a carbon steel sleeve around the entire area. Flemish splices offer the most efficient use of capacity.

The core of the wire rope used in our Eye & Eye Wire Rope Slings can be made of several different materials, including steel or natural fibers. Our steel wire rope slings are made with Extra Improved Plowed Steel (EIPS) around an Independent Wire Rope Core (IWRC) for the ultimate in strength and durability.

Learn more about the wire rope we use at WireCo