If you’re searching for guidance on custom lifting solutions for irregularly shaped or oversized loads, you’ve come to the right place. We understand the unique challenges that non-standard loads present in your lifting operations, from uneven weight distribution to unconventional attachment points. At Tway Lifting, we specialize in engineering custom lifting beams and spreader bars that solve these complex rigging challenges while maintaining the highest safety standards.

Designing custom lifting beams and spreader bars for non-standard loads is a sophisticated engineering process that requires careful analysis of load characteristics, environmental conditions, and regulatory compliance requirements. The process begins with defining the specific challenges of your non-standard load—whether it’s an irregular shape, multiple centers of gravity, or unusual attachment points—then progresses through detailed engineering calculations, material selection, and rigorous testing protocols to ensure safe and efficient lifting operations.

TL;DR Summary:

• Non-standard loads with irregular shapes or uneven weight distribution require custom-engineered solutions to prevent the 90% of lifting accidents that trace back to inadequate equipment or procedures

• Key design factors include load characteristics, available headroom, environmental conditions, and compliance with OSHA 1926.251 requirements for 125% proof testing

• The engineering process involves finite element analysis (FEA) for stress visualization, selection of materials like high-strength steel or carbon fiber composites, and comprehensive testing per ASME BTH-1 standards

• Safety best practices require daily inspections by competent personnel, adherence to ASME B30.20 maintenance schedules, and proper documentation of all testing and certifications

• Selecting the right partner means finding providers with proven experience in complex lifting solutions, IoT integration capabilities, and a track record of ROI delivery through prevented injuries and operational efficiency

• Tway Lifting offers custom solutions that deliver a 6:1 return on investment through enhanced safety compliance and reduced incident costs

Quick Tip: Always verify that your custom lifting equipment provider can demonstrate compliance with both OSHA and ASME standards through proper documentation and proof testing certificates—this single step can prevent costly accidents and regulatory violations.

The complexity of modern lifting operations demands more than standard solutions. As we explore the intricacies of custom lifting equipment design, we’ll guide you through each critical consideration that ensures your non-standard loads are handled safely, efficiently, and in full compliance with regulatory requirements.

What Are Non-Standard Loads and Why Do They Present Unique Lifting Challenges?

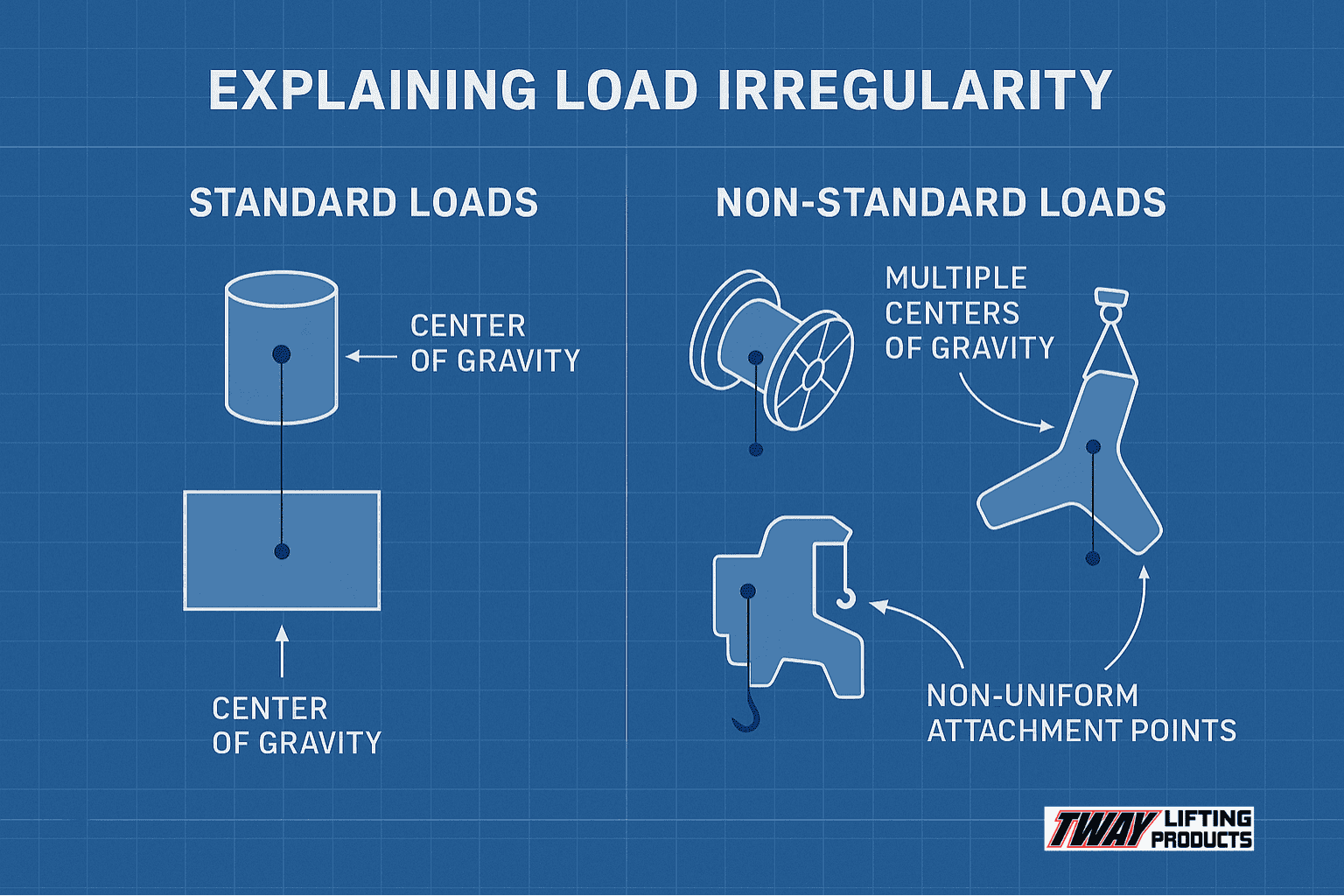

Non-standard loads are materials with irregular shapes, uneven weight distribution, or unconventional attachment points that prevent the use of standard lifting equipment. These loads create unique challenges that require specialized rigging solutions to ensure safe and effective lifting operations. Understanding these challenges helps engineers design appropriate custom lifting systems.

How Are Non-Standard Loads Defined in Lifting Operations?

Non-standard loads are characterized by irregular shapes, uneven weight distribution, or unconventional attachment points that prevent use of standard lifting equipment. These materials deviate from conventional geometric forms such as rectangular beams, cylindrical pipes, or symmetrical containers.

Loads with multiple centers of gravity require custom design to ensure stability during lifting operations. The complexity increases when weight distribution shifts unpredictably or when structural components create asymmetrical loading patterns.

Examples include rebar bundles requiring five lower rigging points and two upper rigging points with 5,000 lb capacity. Other non-standard loads encompass precast concrete elements with embedded lifting points, wind turbine components, and subsea equipment with complex geometries.

Common Non-Standard Load Categories:

- Irregularly shaped precast concrete elements

- Long, flexible materials like cable reels

- Equipment with protruding components

- Multi-component assemblies requiring synchronized lifting

What Common Obstacles Do Non-Standard Loads Create for Rigging Equipment?

The common obstacles non-standard loads create for rigging equipment include unpredictable load behavior, incompatible attachment points, and stress patterns that exceed standard equipment design limits.

The most significant dangers in lifting operations are overturns, collapses, and dropped loads associated with equipment handling. Non-standard loads amplify these risks through unpredictable load behavior and stress patterns that exceed standard equipment capabilities.

Irregular shapes and uneven weight distribution create stress concentrations that standard equipment cannot safely handle. These stress points often occur at connection interfaces where load geometry conflicts with equipment design assumptions.

A 2019 OSHA analysis revealed that 90% of lifting accidents trace back to inadequate pre-use inspections or human error in following established protocols. Non-standard loads compound these risks by requiring specialized knowledge and custom procedures that deviate from standard practices.

Primary Equipment Obstacles:

- Insufficient attachment points for load geometry

- Incompatible sling angles causing excessive stress

- Standard beam lengths inadequate for load span

- Load rotation during lifting due to shifting center of gravity

Non-standard loads demand custom lifting beams and spreader bars engineered specifically for their unique characteristics, making proper design and fabrication critical for operational safety and efficiency.

What Key Factors Influence the Design of Custom Lifting Beams and Spreader Bars?

The key factors that influence custom lifting beam and spreader bar design include load characteristics, environmental conditions, and regulatory requirements. These factors determine equipment selection, material choices, and safety protocols for successful lifting operations.

Load characteristics, site conditions, and compliance requirements work together to shape every aspect of custom lifting equipment design. The following sections detail how these factors impact specific design decisions.

How Do Load Shape, Size, and Weight Affect Design Choices?

Load shape, size, and weight affect design choices by determining whether engineers use lifting beams or spreader bars, how attachment points are configured, and what structural forces must be managed during the lift.

Load characteristics determine whether engineers select lifting beams or spreader bars for custom applications. Spreader bars handle compression forces and cost less to manufacture, while lifting beams manage bending forces and require minimal headroom during operations.

Attachment point configuration critically affects load distribution and prevents dangerous stress concentrations. The number and positioning of connection points must align with the load’s center of gravity and structural weak points.

Design flexibility options include:

- Adjustable spans for varying load dimensions

- Modular components for multiple applications

- Removable attachment hardware

- Telescoping beam sections

Modulift manufactures modular spreader beams with capacities reaching 3,000 tonnes and spans extending 100 meters, demonstrating the scalability of custom solutions for massive industrial loads.

Which Environmental and Site Conditions Must Be Considered?

Environmental and site conditions directly impact equipment selection and material specifications. Available vertical clearance determines whether lifting beams (requiring less headroom) or spreader bars (needing more clearance) suit the application.

Material selection addresses environmental challenges through advanced composites and specialized coatings. Carbon fiber composites deliver 40% weight savings compared to aluminum while providing superior resistance to corrosive environments and extreme temperatures.

Critical site factors include:

- Overhead clearance limitations

- Weather exposure duration

- Temperature extremes

- Chemical exposure risks

Electric and hybrid-powered lifting equipment becomes increasingly prevalent as companies prioritize sustainability requirements and reduce carbon emissions from industrial operations.

How Do Safety and Regulatory Compliance Requirements Impact Design?

Safety regulations establish mandatory testing and marking requirements for custom lifting equipment. OSHA 1926.251 requires all custom lifting accessories undergo proof-testing to 125% of their rated load capacity before initial use in the field.

Welded end attachments face more stringent testing standards, requiring proof-testing at twice their rated capacity per OSHA regulations. All custom lifting accessories must display clear markings indicating their safe working load limits.

Compliance requirements include:

- Initial proof-testing documentation

- Safe working load markings

- Regular inspection schedules

- Material certification records

ASME B30.20 establishes inspection intervals based on service classifications: normal service requires annual inspections, heavy service needs semi-annual checks, and severe service demands quarterly evaluations. These requirements directly influence design durability and material selection for long-term compliance.

Custom lifting equipment design balances load requirements, environmental challenges, and regulatory compliance to create safe, efficient solutions for non-standard lifting operations.

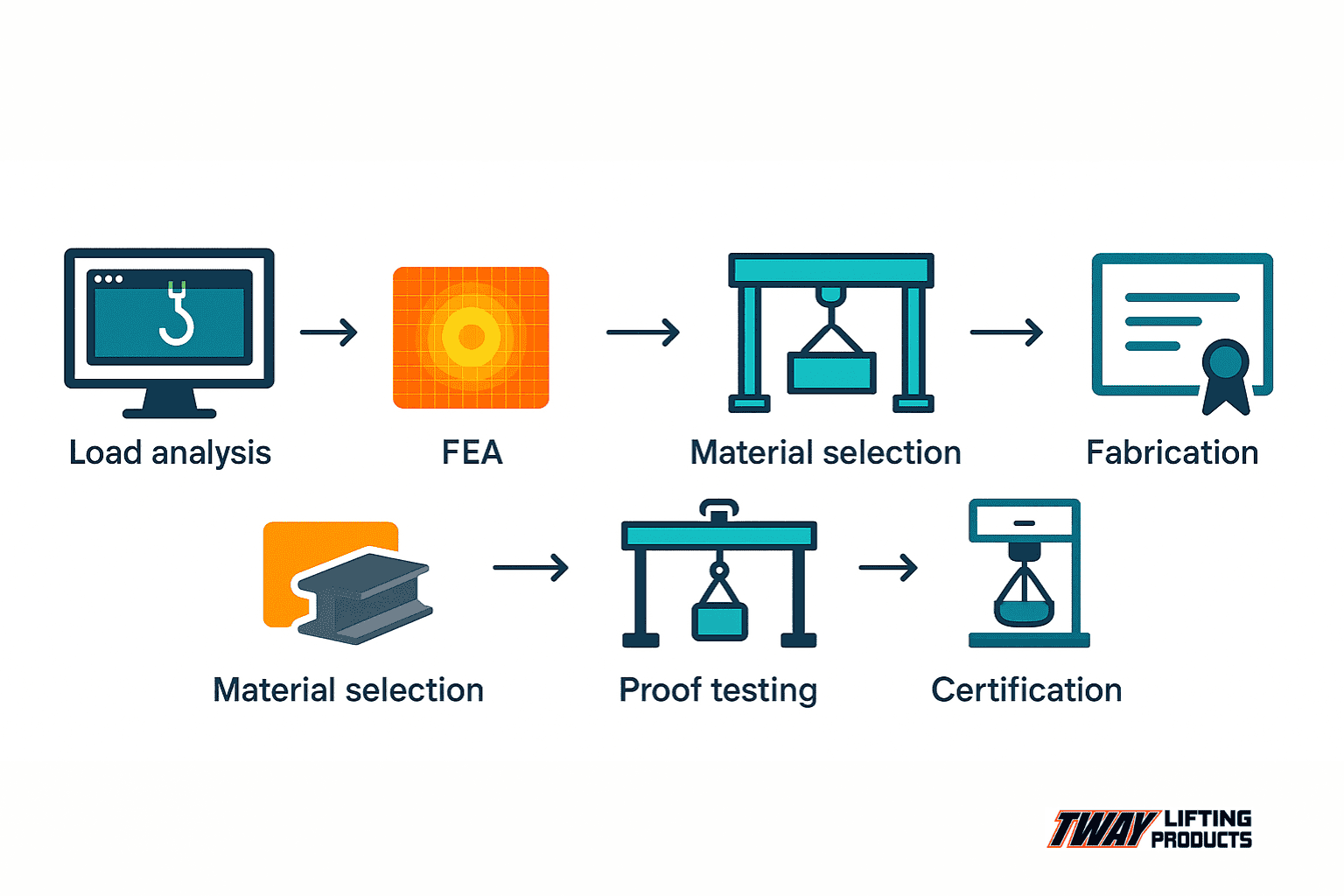

How Is the Design Process for Custom Lifting Beams and Spreader Bars Conducted?

The design process for custom lifting beams and spreader bars involves systematic engineering analysis, material selection, and rigorous testing protocols to ensure safe handling of non-standard loads. This comprehensive approach integrates advanced computational tools, industry standards, and practical fabrication considerations to deliver reliable lifting solutions.

The following sections detail the engineering calculations, material choices, and certification requirements that drive successful custom lifting equipment design.

What Engineering Calculations Are Involved in Designing Safe Lifting Solutions?

Engineering calculations for custom lifting solutions center on stress analysis, load distribution modeling, and structural optimization using advanced computational methods. Finite Element Analysis (FEA) allows engineers to visualize stress distributions, identify potential failure points, and optimize design for strength and weight throughout the lifting device structure.

Engineers must calculate forces including tension in slings and compressive or bending stresses in the beam to ensure safe load handling. Computer-aided engineering (CAE) tools simulate and analyze stresses throughout the lifting device structure, enabling precise prediction of performance under various loading conditions.

These calculations form the foundation for material selection and dimensional specifications that follow industry safety standards.

How Are Materials and Fabrication Methods Chosen?

Material selection for custom lifting equipment prioritizes strength-to-weight ratio, weldability, and environmental resistance based on specific application requirements. High-strength, low-alloy (HSLA) steels are commonly used for their excellent strength-to-weight ratio and proven performance in demanding lifting applications.

ASTM A1001 standard specification covers high-strength steel castings offering good weldability and fracture toughness for critical structural components. Carbon fiber and composite materials are emerging as alternatives, offering significant weight savings though at higher cost than traditional steel options.

Fabrication methods focus on minimizing welding to reduce manufacturing costs and potential stress concentrations, as demonstrated by Basepoint Engineering’s optimized designs with minimal welding requirements.

What Role Does Testing and Certification Play in the Design Process?

Testing and certification requirements ensure custom lifting accessories meet mandatory safety standards before deployment in lifting operations. Custom lifting accessories must undergo proof testing before initial use per OSHA requirements, typically at 125% of rated load capacity.

ASME BTH-1 provides design criteria including material specifications, welding procedures, and structural integrity requirements for below-the-hook lifting devices. CE Marking indicates conformity with European Machinery Directive 2006/42/EC for European markets, while documentation of all inspections and proof tests is mandated by ASME B30.20.

These certification processes validate design calculations and material choices, providing essential safety verification before equipment enters service for handling non-standard loads.

What Are the Best Practices for Ensuring Safety and Compliance with Custom Lifting Devices?

Custom lifting devices require adherence to comprehensive safety standards and rigorous compliance protocols to prevent workplace accidents and ensure regulatory conformity. Establishing proper safety practices reduces liability while maximizing equipment performance and operational efficiency.

What Standards and Certifications Govern Custom Lifting Equipment in the US?

The primary standards governing custom lifting equipment in the US include mandatory federal regulations and voluntary consensus standards. OSHA 1926.251 provides mandatory workplace safety regulations for rigging equipment used in material handling operations, establishing baseline requirements for all employers. ASME B30.20 details comprehensive safety requirements covering construction, installation, operation, inspection, and maintenance of below-the-hook lifting devices throughout their service life.

Additional governing standards include:

- ASME BTH-1 establishing design criteria for lifting devices with specific material specifications and welding procedures

- ISO 16881 specifying global safety and strength requirements for lifting devices

- ANSI/ACCA standards addressing quality assurance in manufacturing processes

- AWS D14.1 covering structural welding for industrial applications

These standards work together to create a comprehensive regulatory framework ensuring custom lifting equipment meets both safety and performance requirements across all phases of design, manufacturing, and operation.

How Should Inspection and Maintenance Be Managed for Custom Solutions?

Inspection and maintenance protocols for custom lifting solutions must follow structured schedules with documented procedures performed by qualified personnel. A competent person must inspect rigging equipment daily before use, with more frequent inspections required when service conditions involve exposure to corrosive environments, extreme temperatures, or heavy-duty cycles per OSHA regulations.

Critical Inspection Requirements:

- Visual inspection of all structural components, welds, and connection points

- Load testing verification according to manufacturer specifications

- Documentation of all findings with immediate removal of defective equipment from service

- Periodic recertification based on usage intensity and environmental conditions

EN 13155 provides European standards for non-fixed load lifting attachments, while LOLER (Lifting Operations and Lifting Equipment Regulations) governs UK lifting operations with similar principles applicable to US operations. These international standards offer additional best practices for inspection frequencies and maintenance procedures.

Regular maintenance schedules should include lubrication of moving parts, replacement of wear components, and verification of safety factors to maintain equipment integrity throughout its operational lifespan. This systematic approach to inspection and maintenance ensures custom lifting devices continue meeting safety standards while providing reliable service for non-standard load applications.

How Can You Select the Right Partner for Designing and Manufacturing Custom Lifting Equipment?

Selecting the right partner for custom lifting equipment requires evaluating technical expertise, industry experience, and technological capabilities. The ideal provider demonstrates proven success across diverse sectors while offering advanced monitoring and maintenance solutions that maximize equipment reliability and operational efficiency.

What Qualities Should You Look for in a Custom Lifting Solutions Provider?

A qualified custom lifting solutions provider demonstrates global expertise through successful case studies across construction, subsea, and wind energy industries. These providers possess capability to advise on complex lifting rig planning beyond just equipment design, ensuring comprehensive project support from concept to implementation.

Modern providers integrate Internet of Things (IoT) sensors for real-time monitoring of load weight, tension, and equipment health. This technology enables operators to track performance metrics continuously and identify potential issues before they escalate. Advanced providers also offer predictive maintenance capabilities through AI and machine learning algorithms that analyze equipment data patterns to reduce downtime and prevent costly failures.

Additional essential qualities include:

- Certified engineering teams with specialized lifting equipment credentials

- In-house fabrication capabilities with quality control systems

- Comprehensive testing facilities for proof testing and validation

- 24/7 technical support for emergency situations

The combination of technical expertise, advanced technology integration, and comprehensive service capabilities distinguishes leading providers in the custom lifting equipment market.

How Important Is Experience with Non-Standard Loads in Your Selection?

Experience with non-standard loads proves critical when selecting a custom lifting partner, as specialized knowledge directly impacts project success and safety outcomes. Companies like Modulift showcase wide range of custom solutions with global recognition in specialized lifting equipment, demonstrating the depth of expertise required for complex applications.

Experience with integrated fork pockets and multi-point rigging systems demonstrates practical custom solution capability that translates to real-world problem-solving skills. Providers with documented success handling irregular geometries, uneven weight distributions, and unique attachment point configurations offer greater confidence in project execution.

Drone-assisted lifting emerging as solution for lightweight operations in hard-to-reach areas represents cutting-edge capability that forward-thinking providers incorporate into their service offerings. This innovation demonstrates adaptability and commitment to advancing lifting technology.

Key experience indicators include:

- Portfolio of successful non-standard load projects across multiple industries

- Case studies showing creative solutions for unique lifting challenges

- References from clients with similar complex lifting requirements

- Documented safety records for non-standard applications

Selecting a partner with extensive non-standard load experience ensures access to proven methodologies and reduces project risk while maximizing operational success.

How Can Tway Lifting Help with Custom Lifting Beams and Spreader Bars for Non-Standard Loads?

Tway Lifting provides comprehensive custom lifting solutions specifically engineered for non-standard loads that challenge conventional rigging equipment. The company specializes in designing, manufacturing, and supporting custom lifting beams and spreader bars that address unique operational requirements across diverse industries.

What Custom Lifting Solutions Does Tway Lifting Offer for Unique Rigging Challenges?

Tway Lifting offers engineered custom lifting solutions that deliver proven return on investment through enhanced safety and operational efficiency. Compliance with safety standards through proper equipment like spreader bars delivers a 6:1 return on investment, according to industry analysis. This ROI calculation includes savings from prevented injuries (averaging $43,000 per incident) and reduced insurance costs.

The company provides:

- Custom-engineered lifting beams for loads requiring precise load distribution

- Specialized spreader bars designed for compression force applications

- Multi-point rigging systems for complex geometries

- Modular lifting solutions for variable load configurations

Custom overhead cranes range from $50,000 to over $500,000 depending on specific operational needs, with Tway Lifting providing comprehensive engineering support throughout the design and implementation process.

What Are the Main Takeaways About Designing Custom Lifting Beams and Spreader Bars for Non-Standard Loads?

The main takeaways about designing custom lifting beams and spreader bars for non-standard loads are that engineering analysis, material selection, and regulatory compliance form the foundation of safe, effective custom lifting solutions.

The custom lifting equipment sector represents a rapidly expanding market driven by increasing industrial complexity and safety requirements. The global lifting equipment market was estimated at $77.58 billion in 2024, projected to grow at a CAGR of 4.8% from 2025 to 2032. The industrial lifting equipment market is expected to grow from $82.36 billion in 2024 to $128.50 billion by 2035.

Key considerations include:

- Engineering analysis must account for irregular load distributions and unique attachment points

- Material selection balances strength, weight, and environmental resistance

- Compliance with OSHA 1926.251 and ASME standards ensures operational safety

- Custom solutions offer greater efficiency and productivity gains over time despite higher upfront costs

The heavy lifting equipment market exceeded $25 billion in 2024, forecasted to grow at a CAGR of 5.8% through 2034, reflecting increasing demand for specialized lifting solutions that address non-standard applications safely and efficiently.