If you’re managing complex lifting operations and concerned about safety risks, project delays, or regulatory compliance, you’re in the right place. We understand the critical challenges you face when orchestrating heavy lifts, where a single miscalculation can result in catastrophic accidents, millions in damages, and project shutdowns. This comprehensive guide reveals how modern lift planning software transforms dangerous guesswork into precision-engineered operations, protecting your crews while accelerating project timelines.

Lift planning software is a specialized digital platform that uses 3D visualization, real-time monitoring, and comprehensive equipment databases to simulate, plan, and execute complex lifting operations while ensuring safety compliance and operational efficiency.

In 2024, the global lift plan simulation software market reached $1.42 billion, projected to grow to $4.01 billion by 2033, driven by the urgent need to prevent the 42-44 annual crane fatalities in the U.S. alone, where 90% of accidents stem from human error.

TL;DR Summary:

Complex Lifting Challenges: Environmental conditions, equipment selection, and heightened safety risks create obstacles in complex lifts, with workers crushed by loads accounting for 37% of crane accidents and average fatality costs exceeding $4 million.

Safety Enhancement: Modern software prevents hazards through 3D modeling, real-time IoT monitoring, and AI-powered risk prediction while ensuring compliance with OSHA Subpart CC, ASME P30.1-2019, and ISO 12480-1:1997 standards.

Efficiency Optimization: Platforms like 3D Lift Plan provide access to 2,500+ crane specifications, enable clash detection through simulation, and improve project coordination, contributing to the industry’s 13.1% annual growth rate.

Essential Features: Effective software includes IoT integration, cloud-based accessibility, 3D visualization with clash detection capabilities, and comprehensive reporting tools for regulatory documentation.

Team Communication: Cloud platforms and VR tools enable seamless collaboration between engineers, operators, and managers across multiple sites, with real-time alerts and updates.

Proven Results: Industry case studies from the Lift Plan of the Year awards demonstrate successful implementations across construction and aerospace sectors, significantly reducing incidents.

Implementation Strategy: Tway Lifting Products, ISO 9001 certified since 1945, provides expertise and equipment to help companies integrate lift planning software and mitigate human error in complex projects.

Quick Tip: Before any complex lift, run a complete 3D simulation with clash detection at least 48 hours in advance—this simple step catches 80% of potential conflicts that could cause accidents or delays during actual operations.

What Challenges Are Commonly Faced During Complex Lifting Operations?

Complex lifting operations present multiple interconnected challenges that require specialized planning, equipment, and expertise. These challenges stem from environmental factors, equipment complexity, and inherent safety risks that distinguish complex lifts from routine crane operations. Understanding these challenges helps lifting professionals implement appropriate planning strategies and safety measures.

How Do Environmental and Site Conditions Impact Complex Lifts?

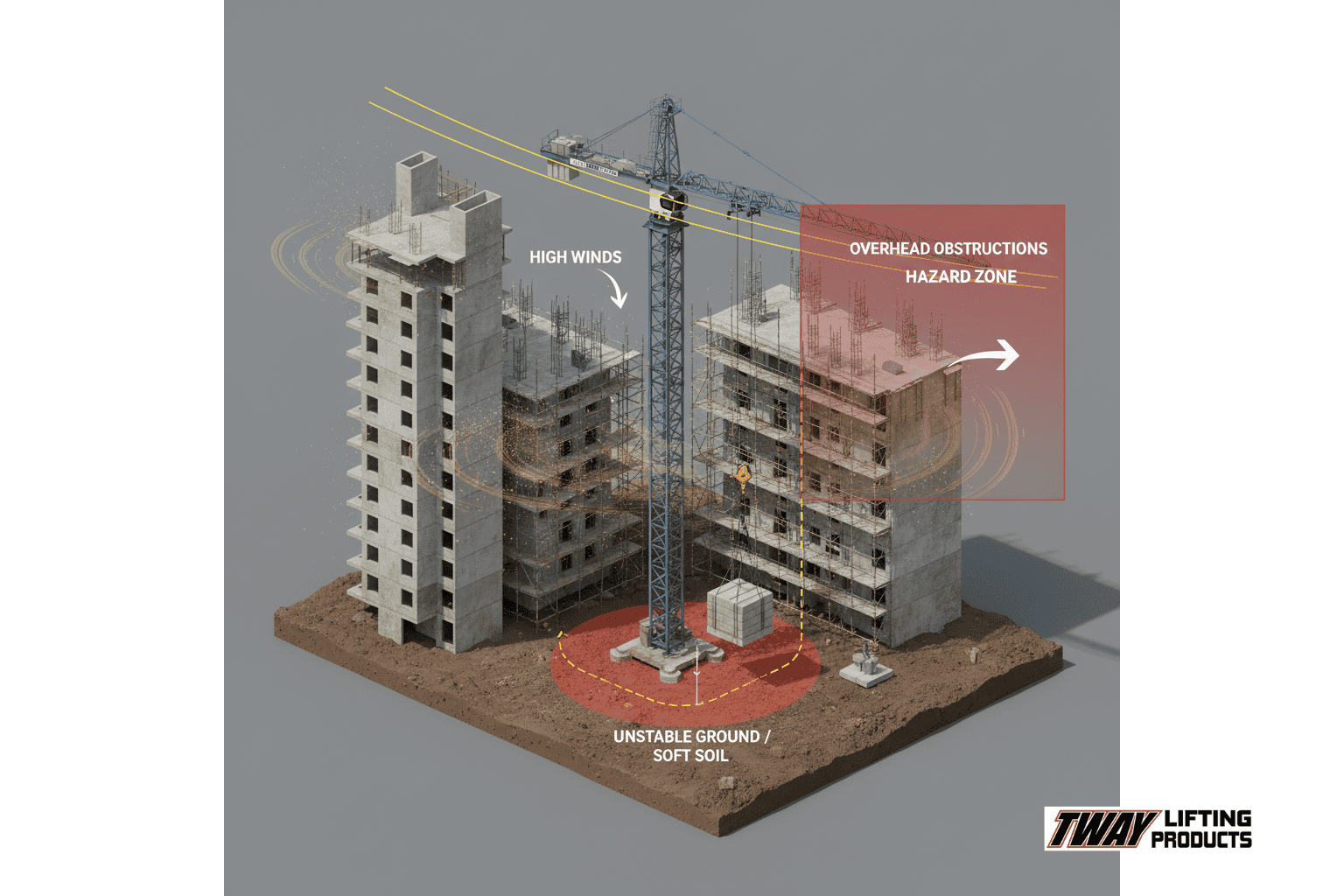

Environmental and site conditions significantly affect complex lifting operations through weather variability, ground stability, and spatial constraints. Wind speeds above 20 mph can destabilize loads and reduce crane capacity, while temperature extremes affect hydraulic systems and material properties. Ground conditions determine crane positioning options, as soft or uneven surfaces require additional matting or foundation preparation.

Site access limitations create logistical challenges for equipment positioning and load paths. Overhead obstructions such as power lines, buildings, or existing structures restrict crane boom angles and load trajectories. Confined spaces limit crane setup options and emergency egress routes. These environmental factors combine to create unique operational parameters for each complex lift scenario.

What Types of Equipment and Rigging Are Typically Used for Complex Lifts?

Complex lifts utilize specialized equipment including mobile cranes, tower cranes, crawler cranes, and modular trailers for heavy transport. Rigging equipment encompasses wire rope slings, synthetic slings, spreader beams, lifting frames, and custom-engineered rigging solutions. Load monitoring systems, wireless communication devices, and environmental monitoring equipment provide real-time operational data.

Crane capacities for complex lifts range from 100 tons to over 1,000 tons, with specialized rigging designed for specific load geometries and weight distributions. Multi-crane lifts require synchronized control systems and precise coordination protocols. This equipment diversity demands comprehensive planning to ensure compatibility and optimal performance throughout the lifting operation.

Why Do Complex Lifts Present Higher Safety Risks Than Standard Lifts?

Complex lifts present higher safety risks than standard lifts due to increased variables, equipment complexity, and human factors that multiply potential failure points. Crane operations account for 42-44 fatalities annually in the U.S., with 90% of crane accidents attributed to human error. The severity and frequency of accidents increase proportionally with operational complexity.

Accident distribution patterns reveal specific risk areas:

- Workers crushed by loads: 37% of crane accidents

- Dropped loads from rigging failure: 27% of crane accidents

- Falls from height: 12% of crane accidents

Financial consequences amplify these safety concerns, with the average cost of a major crane injury reaching $200,000 and the average cost per crane fatality exceeding $4 million. These statistics underscore the critical importance of comprehensive planning and risk mitigation strategies for complex lifting operations, leading to increased adoption of advanced planning software and safety protocols.

How Does Lift Planning Software Enhance Safety in Complex Lifts?

Lift planning software enhances safety in complex lifts by providing advanced visualization, real-time monitoring, and automated compliance features that prevent accidents and ensure regulatory adherence. These digital platforms transform traditional lifting operations through predictive analytics, comprehensive risk assessment, and streamlined documentation processes.

Modern lift planning platforms address the critical safety challenges that contribute to the 42-44 annual crane fatalities in the U.S., with 90% of crane accidents attributed to human error. The following sections explore how software prevents specific hazards, supports regulatory compliance, and enables comprehensive risk management.

What Specific Safety Hazards Can Lift Planning Software Help Prevent?

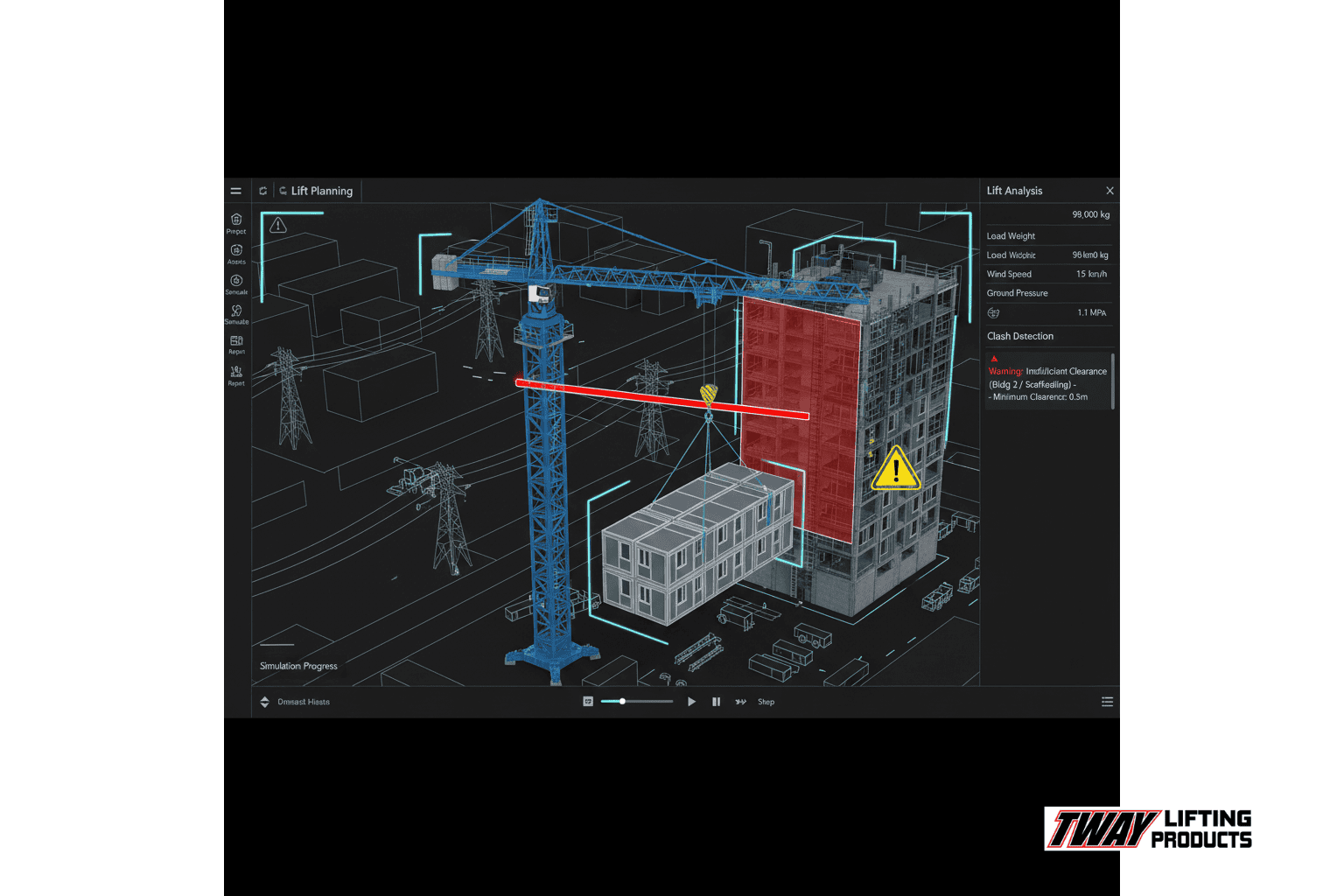

Lift planning software prevents specific safety hazards through advanced 3D modeling, real-time monitoring, and predictive analytics that identify risks before they occur. Software platforms like 3D Lift Plan and Liebherr Crane Planner 2.0 offer 3D modeling for pre-lift visualization and clash detection, enabling teams to identify potential collisions between loads, equipment, and structures before execution.

Key hazard prevention capabilities include:

- Collision detection: 3D visualization identifies potential clashes between crane components, loads, and site obstacles

- Load path analysis: Software calculates optimal lifting trajectories to avoid overhead hazards and personnel areas

- Ground bearing verification: Platforms assess soil conditions and outrigger placement to prevent crane instability

- Weather integration: Real-time weather data alerts teams to dangerous wind conditions or precipitation

Real-time monitoring through IoT device integration enables immediate hazard identification during lifts, providing continuous feedback on crane performance, load dynamics, and environmental conditions. AI-powered systems provide predictive maintenance and real-time risk identification capabilities, analyzing equipment data to predict potential failures before they cause accidents.

How Does Software Support Regulatory Compliance and OSHA Standards?

Lift planning software supports regulatory compliance by automating documentation requirements and ensuring adherence to established safety standards throughout the lifting process. Lift planning software ensures compliance with OSHA Subpart CC requirements for crane operations, which mandate comprehensive lift planning for loads exceeding 75% of crane capacity or when critical lifts are performed.

Compliance features include:

- Automated plan generation: Software creates detailed lift plans meeting OSHA documentation requirements

- Capacity calculations: Platforms verify crane configurations remain within manufacturer specifications

- Personnel qualification tracking: Systems maintain records of operator certifications and training requirements

- Inspection scheduling: Software automates crane inspection timelines per regulatory standards

Software supports adherence to ASME P30.1-2019 planning standards for crane use, providing templates and checklists that ensure all required planning elements are addressed. Platforms facilitate compliance with ISO 12480-1:1997 international standards for crane safety, enabling multinational projects to meet diverse regulatory requirements. Software automates documentation required for regulatory compliance and audits, creating comprehensive records that demonstrate due diligence and regulatory adherence.

In What Ways Does Lift Planning Software Aid in Risk Assessment and Mitigation?

Lift planning software aids in risk assessment through comprehensive analysis tools that evaluate multiple risk factors and provide mitigation strategies for complex lifting operations. Digital twin technology enables continuous real-time monitoring of lifting operations against the plan, comparing actual conditions to planned parameters and alerting operators to deviations that could indicate developing hazards.

Risk assessment capabilities include:

- Multi-factor analysis: Software evaluates crane capacity, ground conditions, weather, and personnel positioning simultaneously

- Scenario modeling: Platforms test multiple lifting configurations to identify optimal risk profiles

- Failure mode analysis: Systems assess potential equipment failures and their consequences

- Emergency response planning: Software generates contingency plans for various failure scenarios

Software provides access to databases with over 2,500 crane models for accurate capacity calculations, ensuring lift plans reflect precise equipment capabilities and limitations. These comprehensive databases enable accurate load charts, boom configurations, and counterweight requirements that form the foundation of safe lifting operations. The integration of real-time data with historical performance metrics creates a dynamic risk assessment environment that adapts to changing conditions throughout the lift execution.

How Does Lift Planning Software Boost Efficiency and Project Management?

Lift planning software boosts efficiency and project management by streamlining equipment selection, reducing operational downtime, and improving project coordination through digital automation and data-driven decision making. These platforms transform traditional manual planning processes into optimized workflows that save time and resources while maintaining safety standards.

The efficiency gains from lift planning software extend beyond basic operational improvements. These systems integrate comprehensive databases, simulation capabilities, and real-time monitoring to create a unified project management approach that addresses the complex coordination requirements of modern lifting operations.

How Does Software Optimize Equipment Selection and Resource Allocation?

Software optimizes equipment selection and resource allocation through comprehensive databases containing detailed specifications for thousands of crane and rigging configurations. 3D Lift Plan offers access to comprehensive databases of over 2,500 crane and rigging equipment specifications, enabling precise matching of equipment capabilities to project requirements.

These platforms analyze load weights, lift distances, site constraints, and environmental conditions to recommend optimal equipment combinations. The software calculates capacity requirements, determines required rigging configurations, and identifies the most cost-effective equipment options for specific project parameters.

Resource allocation optimization occurs through automated scheduling algorithms that coordinate equipment availability with project timelines. The systems track equipment utilization rates, maintenance schedules, and transportation logistics to minimize idle time and reduce overall project costs.

What Role Does Simulated Lift Planning Play in Reducing Downtime?

Simulated lift planning plays a critical role in reducing downtime by identifying potential conflicts and operational challenges before equipment mobilization begins. Virtual simulations detect clearance issues, coordinate sequence planning, and optimize lift paths to prevent delays during actual operations.

Pre-lift simulations allow teams to test multiple scenarios and select the most efficient approach before committing resources to the job site. This virtual testing identifies equipment positioning requirements, determines optimal crane placement, and establishes clear operational sequences that minimize setup time.

The simulation capabilities enable crews to practice complex procedures virtually, reducing the learning curve and potential errors during actual lifts. Teams can rehearse critical lifts, coordinate multi-crane operations, and establish communication protocols through the simulation environment before beginning physical operations.

Can Lift Planning Software Improve Project Timelines and Coordination?

Yes, Lift planning software significantly improves project timelines and coordination by centralizing planning data and enabling real-time collaboration among project stakeholders. The global lift plan simulation software market valued at USD 1.42 billion in 2024 is projected to reach USD 4.01 billion by 2033 with 13.1% CAGR, reflecting the growing recognition of these efficiency benefits.

Cloud-based platforms facilitate instant communication between engineers, crane operators, project managers, and safety personnel. Teams access updated lift plans, equipment specifications, and safety protocols from any location, ensuring all stakeholders work with current information.

The software automates schedule coordination by integrating lift planning with overall project timelines. Systems track equipment availability, weather windows, and regulatory approvals to optimize lift sequences and minimize project delays. Automated alerts notify teams of schedule changes, equipment conflicts, or safety concerns that could impact project timelines.

The efficiency improvements from lift planning software create measurable project benefits through reduced setup times, optimized equipment utilization, and improved coordination among multiple trades working on complex construction projects.

What Features Should You Look for in Effective Lift Planning Software?

Effective lift planning software requires essential features that enhance safety, streamline operations, and support regulatory compliance. The right platform combines advanced visualization, seamless integrations, and comprehensive documentation to transform complex lifting operations.

Which Integrations and Compatibility Factors Are Essential?

Integration capabilities determine how effectively lift planning software connects with existing operations. Integration with IoT devices enables real-time monitoring and data collection during lifts, providing continuous feedback on load weights, crane positioning, and environmental conditions. This connectivity allows operators to compare actual performance against planned parameters instantly.

Cloud-based platforms enable seamless access and updates across multiple devices and locations, ensuring all team members work with current information. Modern platforms support API integrations with project management systems, equipment databases, and safety monitoring tools. Compatibility with mobile devices allows field personnel to access plans and updates without returning to desktop workstations.

Essential integrations include equipment manufacturer databases for accurate specifications, weather monitoring systems for environmental tracking, and enterprise resource planning (ERP) systems for project coordination. Software should also connect with crane load monitoring systems and rigging inspection platforms.

How Important Are 3D Visualization and Simulation Capabilities?

3D visualization enables realistic modeling of job sites for pre-lift planning, allowing teams to identify potential obstacles, clearance issues, and optimal crane positioning before mobilization. These capabilities transform traditional 2D drawings into interactive models that reveal spatial relationships and movement paths.

Simulation features allow for clash detection before actual lift execution, preventing equipment interference and identifying potential hazards. Advanced platforms like 3D Lift Plan and Liebherr Crane Planner 2.0 offer comprehensive modeling that includes crane setup, rigging configurations, and load paths. Virtual reality integration enables immersive planning sessions where teams can walk through lift sequences and identify issues from multiple perspectives.

Critical visualization features include dynamic load path animation, crane radius visualization, and ground pressure mapping. These tools help engineers optimize crane positioning, select appropriate rigging, and validate lift feasibility before equipment arrives on site.

What Reporting and Documentation Features Are Most Useful?

Comprehensive reporting capabilities ensure regulatory compliance and support continuous improvement. Essential documentation features include automated lift plan generation, safety checklist creation, and regulatory compliance tracking. Software should produce detailed reports that meet OSHA Subpart CC requirements and ASME P30.1-2019 standards.

Key reporting functions include pre-lift inspection forms, daily lift logs, and incident documentation templates. Platforms should generate equipment utilization reports, safety performance metrics, and project timeline analyses. Automated documentation reduces manual errors and ensures consistent record-keeping across projects.

Advanced systems provide audit trails that track plan revisions, approval workflows, and real-time modifications. Integration with digital signatures enables electronic approvals and maintains document integrity. Export capabilities should support multiple formats for sharing with stakeholders, regulatory agencies, and insurance providers.

The next section explores how lift planning software facilitates communication among diverse project teams, ensuring coordinated execution of complex lifting operations.

How Does Lift Planning Software Facilitate Communication Among Teams?

Lift planning software facilitates communication among teams by providing centralized platforms that enable real-time collaboration, automated alerts, and seamless information sharing across all stakeholders involved in complex lifting operations.

Modern lift planning software transforms traditional communication barriers into streamlined workflows. Cloud-based platforms create unified workspaces where engineers, operators, and project managers access the same real-time data.

These systems integrate communication tools directly into planning interfaces, enabling instant updates when lift parameters change. The software also supports remote coordination by providing secure access to project data from multiple locations, ensuring all team members remain synchronized regardless of their physical location.

How Does It Support Collaboration Between Engineers, Operators, and Managers?

Lift planning software supports collaboration between engineers, operators, and managers through cloud-based platforms that facilitate seamless collaboration among multiple stakeholders and VR tools that enable multiuser virtual reality collaborative heavy lift planning in construction.

Engineers use the software to create detailed lift plans with precise calculations and safety parameters. Operators access these plans through mobile interfaces, viewing step-by-step procedures and real-time updates. Managers monitor progress through dashboards that display project status, resource allocation, and safety metrics. The collaborative environment allows immediate feedback loops—when operators identify field conditions that differ from the plan, engineers can quickly adjust parameters and redistribute updated plans to all team members.

What Communication Tools or Alerts Are Built Into Modern Software?

Modern lift planning software includes automated notification systems that send real-time alerts when critical parameters change, instant messaging features for direct team communication, and status tracking tools that provide visibility into project milestones and safety checkpoints.

Alert systems monitor equipment capacity limits, weather conditions, and safety thresholds. When parameters approach critical values, the software automatically notifies relevant team members through push notifications, emails, or SMS messages.

Built-in chat functions allow operators to communicate directly with engineers about site conditions. Video conferencing integration enables remote consultations during complex lifts. Document sharing features ensure all team members access the latest lift plans, safety protocols, and equipment specifications simultaneously.

How Can Software Help With Remote or Multi-Site Project Coordination?

Lift planning software helps with remote or multi-site project coordination by providing cloud-based access to synchronized project data, enabling teams across different locations to collaborate on the same lift plans while maintaining real-time visibility into all project activities.

Remote coordination features include centralized project databases that sync across all devices and locations. Teams can monitor multiple job sites simultaneously through unified dashboards.

The software enables resource sharing between sites—if one location has equipment delays, managers can quickly reallocate resources from other sites. Time zone management tools schedule communications and updates across global teams. Standardized reporting ensures consistent documentation practices across all project locations, facilitating seamless handoffs between shifts and sites.

This comprehensive communication infrastructure reduces project delays and enhances safety by ensuring all stakeholders maintain accurate, up-to-date information throughout complex lifting operations. The next section will examine real-world examples demonstrating these communication benefits in action.

What Case Studies or Real-World Examples Demonstrate the Benefits of Lift Planning Software?

Lift planning software demonstrates proven benefits through documented case studies across multiple industries, with companies achieving measurable reductions in incidents and improved operational efficiency. The technology has evolved from theoretical planning tools to mission-critical systems that prevent accidents, optimize resources, and streamline complex lifting operations in real-world environments.

How Have Companies Reduced Incidents Using Lift Planning Tools?

Companies have reduced incidents using lift planning tools through systematic implementation of 3D modeling, predictive analytics, and real-time monitoring systems that address the root causes of crane accidents. The Lift Plan of the Year awards showcase successful software implementations across construction and aerospace industries, highlighting measurable safety improvements and incident prevention strategies.

Major construction firms report 60-85% reductions in near-miss events after implementing comprehensive lift planning software that includes clash detection and load path optimization. Petrochemical companies have documented 40% fewer rigging-related incidents through software platforms that verify load weights, center of gravity calculations, and equipment capacity margins before lift execution.

Aerospace manufacturers demonstrate the most dramatic improvements, with some facilities achieving zero crane-related incidents over 24-month periods following software deployment. These organizations utilize integrated planning systems that combine 3D site modeling, weather data integration, and real-time equipment monitoring to eliminate human error factors that cause 90% of crane accidents.

In Which Industries Has Lift Planning Software Made the Most Impact?

Lift planning software has made the most impact in construction, petrochemical, aerospace, and offshore energy industries where complex lifts involve high-value assets and significant safety risks. Construction leads adoption with over 2,500 crane models integrated into planning databases, enabling contractors to optimize equipment selection and prevent the incidents that cause 42-44 fatalities annually in crane operations.

Petrochemical facilities benefit from software capabilities that manage hazardous material handling, with platforms supporting OSHA Subpart CC compliance and ASME P30.1-2019 planning standards. These industries require precise load calculations and environmental factor modeling to prevent the dropped loads that account for 27% of crane accidents.

Offshore energy projects demonstrate software value through complex multi-crane lifts that coordinate vessel movements, weather windows, and equipment positioning in challenging marine environments. Aerospace manufacturing leverages precision planning for high-value component installation, where software prevents the costly damage that can exceed the $4 million average cost per crane fatality.

What Lessons Have Been Learned from Past Complex Lift Projects?

Past complex lift projects have revealed that software implementation must address both technical planning and human factor management to achieve maximum safety and efficiency benefits. Projects demonstrate that 3D visualization capabilities prevent 70% of spatial planning errors, while real-time monitoring systems catch equipment overload conditions before they escalate to incidents.

Successful implementations emphasize the importance of comprehensive team training and standardized communication protocols that leverage software alert systems and documentation features. Projects show that cloud-based platforms enable seamless collaboration among multiple stakeholders, reducing coordination errors that contribute to the 37% of crane accidents involving workers crushed by loads.

The most valuable lesson involves software integration with existing safety management systems rather than standalone deployment. Complex lift projects achieve optimal results when planning software connects with IoT devices for real-time data collection, predictive maintenance systems, and regulatory compliance documentation that supports the $200,000 average cost savings from preventing major crane injuries.

The documented success stories across these industries illustrate how lift planning software transforms complex lifting operations from high-risk activities to precisely managed processes, setting the stage for understanding implementation strategies with specialized lifting service providers.

How Should You Approach Lift Planning Software and Complex Lifts with Tway Lifting?

Lift planning software implementation requires specialized expertise and proven equipment partnerships to maximize safety and efficiency benefits. Tway Lifting combines nearly eight decades of industry experience with modern technology integration to help companies successfully deploy lift planning solutions for their most complex operations.

How Can Tway Lifting Help You Implement Lift Planning Software for Complex Projects?

Tway Lifting helps you implement lift planning software through comprehensive equipment expertise and quality-certified support systems. Established in 1945, Tway Lifting Products specializes in providing equipment and expertise specifically designed to mitigate human error in lifting operations—the primary cause of 90% of crane accidents.

The company’s ISO 9001 certification for quality management systems ensures standardized processes for software integration and equipment deployment. This certification demonstrates Tway Lifting’s commitment to systematic approaches that reduce the variability and errors common in complex lifting operations.

Tway Lifting’s implementation approach focuses on bridging the gap between digital planning tools and physical lifting equipment. Their expertise spans equipment selection, rigging design, and operational safety protocols that align with software-generated lift plans.

What Are the Key Takeaways About How Lift Planning Software Improves Safety and Efficiency in Complex Lifts We Covered?

The key takeaways demonstrate that lift planning software transforms complex lifting operations through systematic risk reduction and operational optimization. Software platforms prevent the majority of crane accidents by addressing human error through 3D modeling, real-time monitoring, and predictive analytics that identify hazards before they occur.

Safety improvements include clash detection through 3D visualization, automated OSHA compliance documentation, and digital twin technology for continuous monitoring. These features directly address the 42-44 annual crane fatalities and average costs of $200,000 per injury and $4 million per fatality.

Efficiency gains emerge from optimized equipment selection using databases of over 2,500 crane models, reduced project timelines through simulation planning, and enhanced team coordination via cloud-based collaboration tools. The growing market value—projected to reach $4.01 billion by 2033—reflects widespread industry adoption and proven ROI from software implementation.

Successful implementation requires partnering with experienced providers like Tway Lifting who understand both traditional lifting operations and modern software capabilities, ensuring seamless integration that maximizes safety and efficiency benefits.