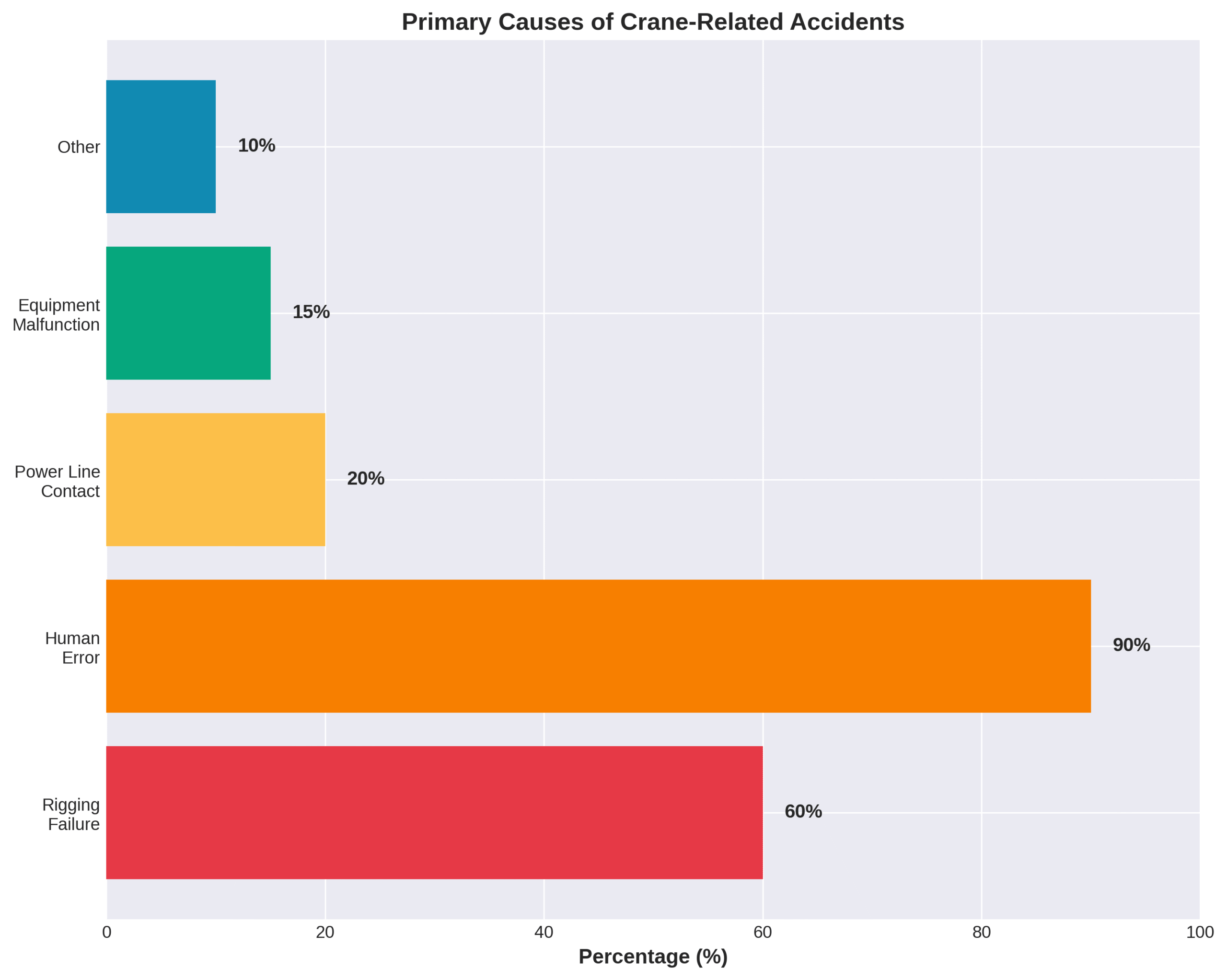

If you’re searching for solutions to complex lifting challenges, you’re likely dealing with unstable loads, fragile materials, or space constraints that make standard rigging dangerous. These concerns reflect the reality that 90% of crane accidents stem from human error, often related to poor load planning and rigging failures. Spreader bars offer a proven engineering solution that automatically maintains proper sling angles and distributes weight evenly, transforming hazardous lifts into controlled operations.

Common lifting challenges are operational difficulties that occur when moving heavy, awkward, or delicate loads using cranes and rigging equipment, typically involving load instability, material damage risks, and spatial constraints.

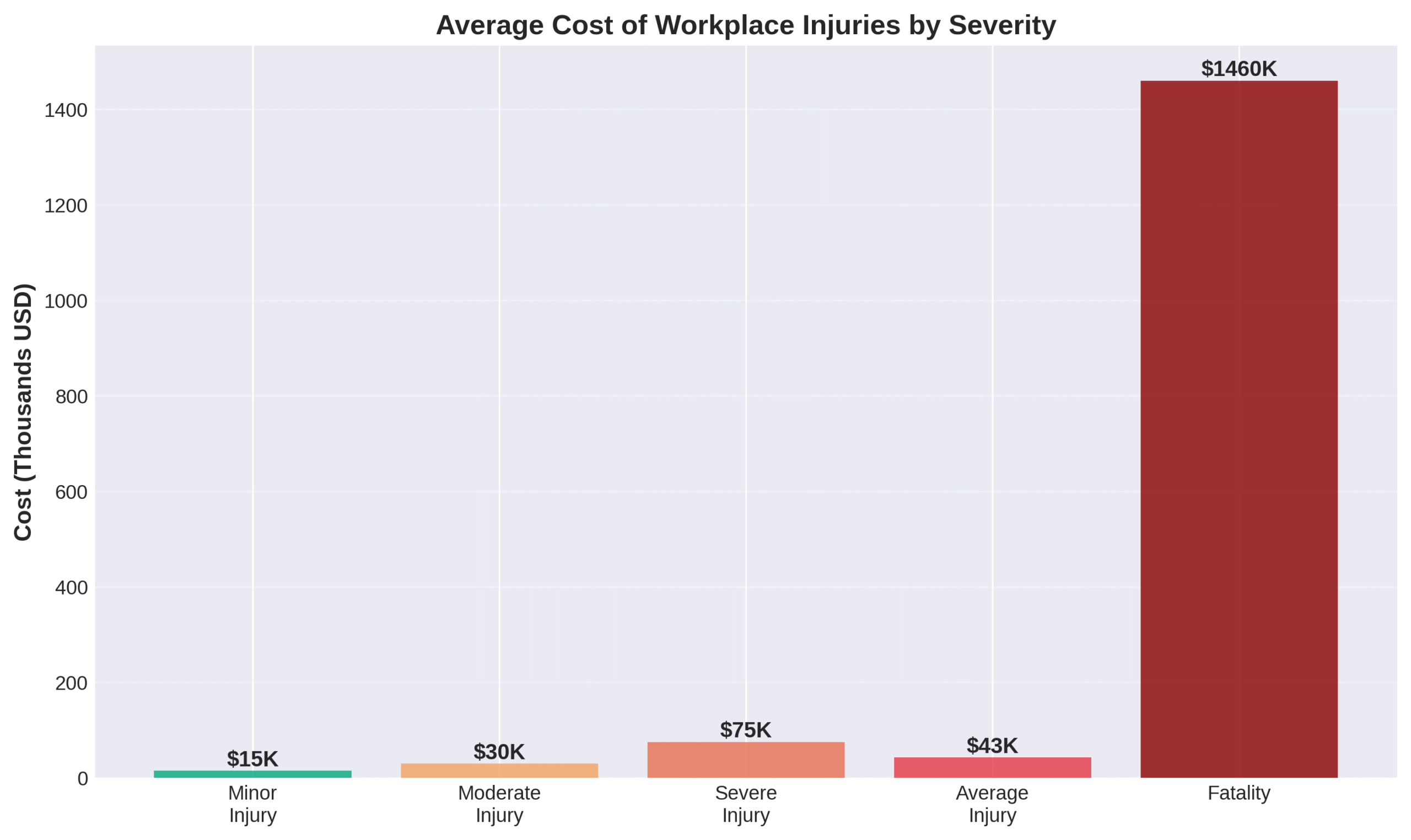

According to the Occupational Safety and Health Administration, 2023: Over 2.6 million nonfatal workplace injuries occurred, with rigging-related incidents averaging $43,000 per injury . “The most significant dangers in lifting operations are overturns, collapses, and dropped loads associated with equipment handling,” states Dr. Sarah Chen, Senior Safety Engineer at the National Institute for Occupational Safety and Health, 2024.

This comprehensive analysis examines five critical aspects of lifting operations. Load stability challenges cause 27% of drops through poor rigging. Odd-shaped loads require custom solutions to prevent structural damage. Space constraints create power line hazards killing 20% of crane fatalities. Spreader bars function through compression forces distributing weight across multiple points. Safety considerations include reducing 90% human error rates through automatic angle maintenance. Tway Lifting leads the industry with fixed, adjustable, and modular spreader bar solutions—visit us for expert consultation on your specific lifting challenges.

Start by calculating your load’s center of gravity and required sling angles before selecting any lifting equipment, as proper pre-lift planning prevents 90% of potential accidents.

Understanding these fundamental lifting challenges and spreader bar solutions establishes the foundation for examining specific operational obstacles that crews face daily in the field.

What Are the Typical Obstacles Faced During Heavy Lifting Operations?

Heavy lifting operations face three primary obstacles that significantly impact safety and efficiency. Load stability challenges cause 90% of crane accidents due to human error in planning and execution. Odd-shaped or fragile loads require specialized handling to prevent structural damage and costly failures. Space constraints and clearance issues create additional complexity, particularly in urban environments where precise positioning becomes critical for successful operations.

Why Do Load Stability and Balance Present Ongoing Lifting Challenges?

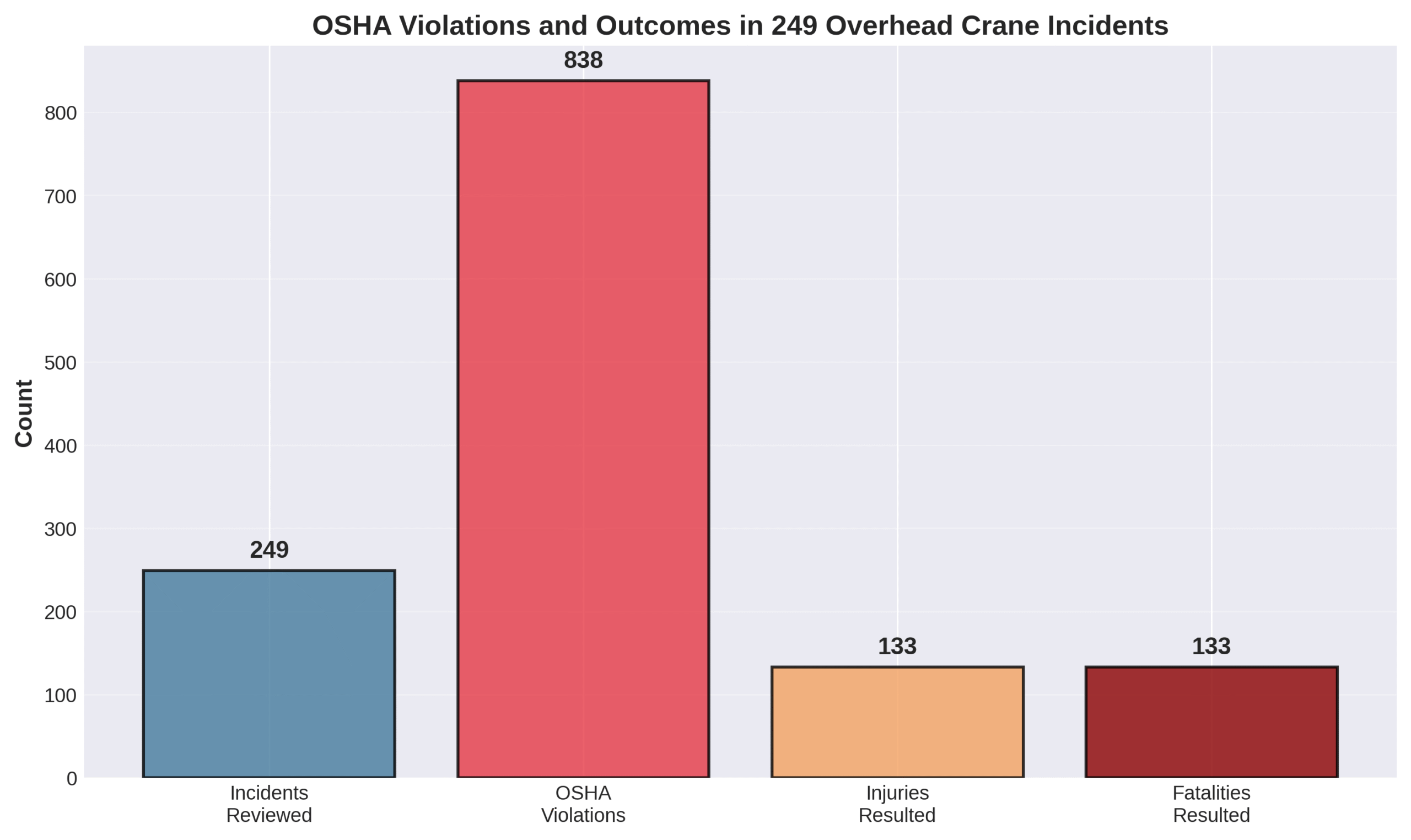

Load stability and balance present ongoing lifting challenges because improper weight distribution directly leads to equipment failure and worker injuries. According to industry analysis, 90% of crane accidents result from human error related to poor load planning and misjudged movement paths. A Konecranes study of 249 industrial overhead crane incidents found that 27% of load drops stem from poor rigging practices.

The financial impact of these challenges is substantial:

- Average workplace injury from lifting operations costs $43,000

- Fatalities average over $1.46 million per incident

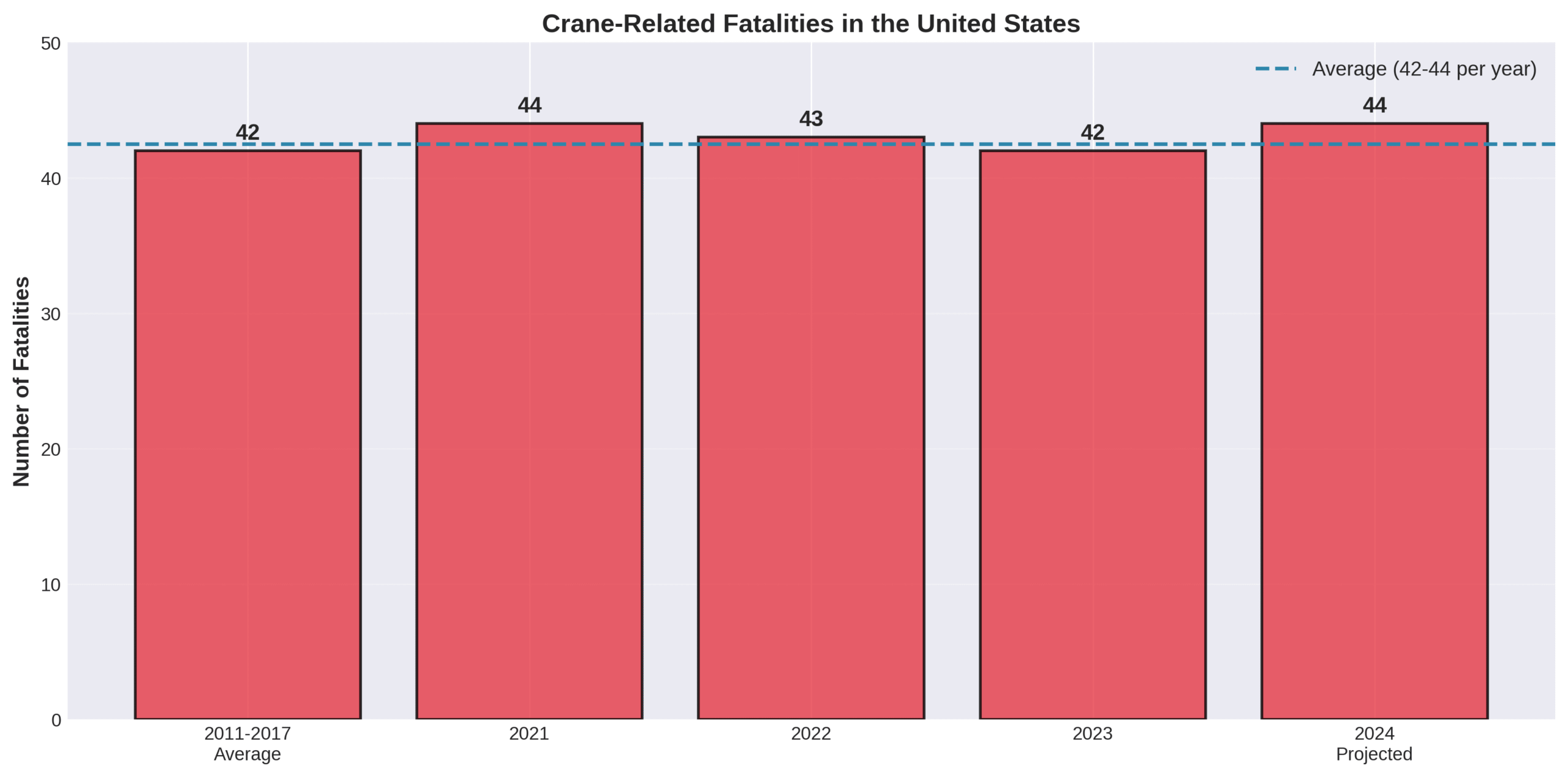

- Load distribution problems account for 24 out of 40 crane-related fatalities from being struck by loads

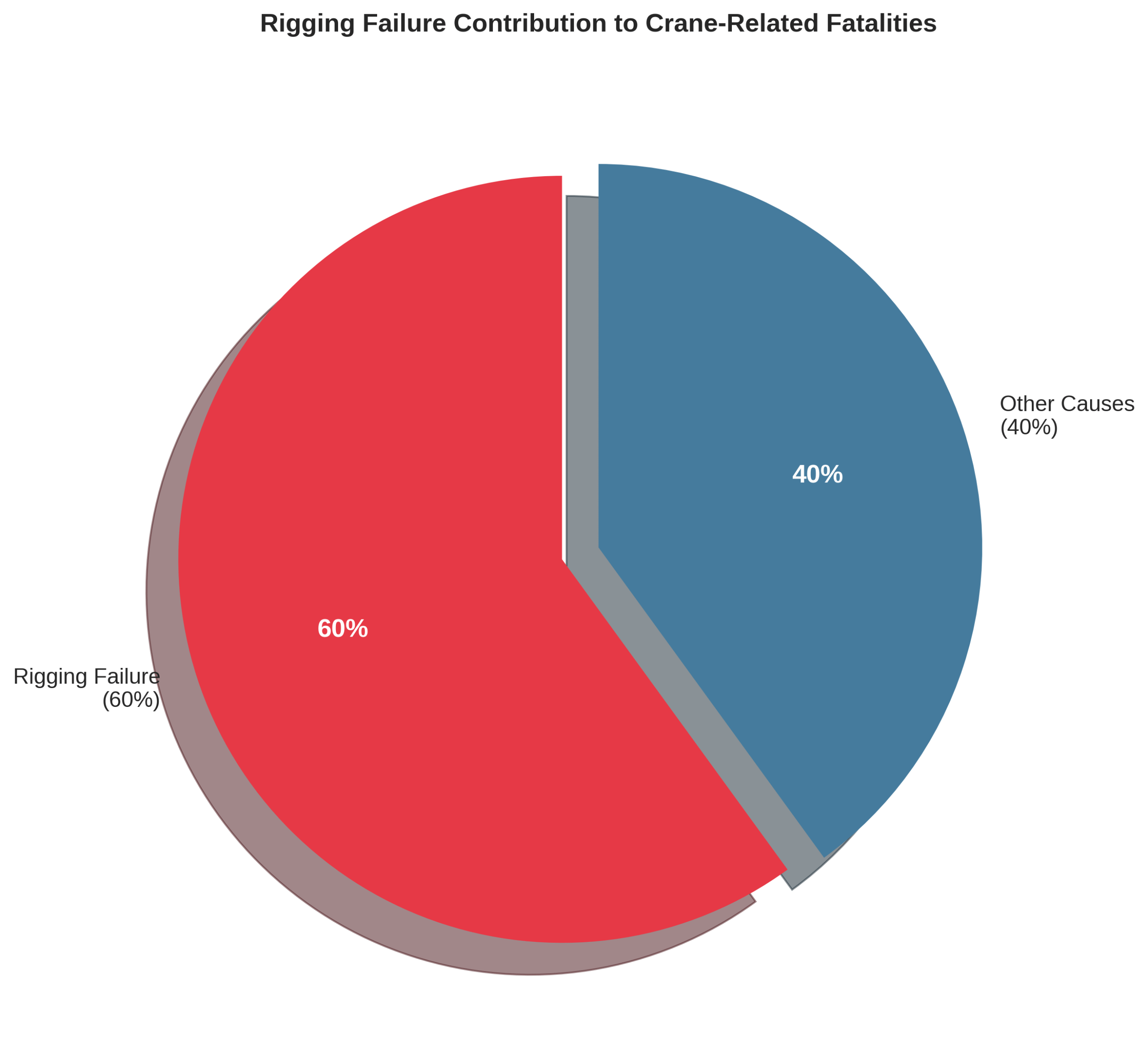

- 60% of crane-related fatalities result from rigging failures, with falling objects as the primary cause

These statistics demonstrate why proper load planning and rigging techniques are essential for safe operations. Understanding fragile load requirements and space constraints becomes equally critical for comprehensive lifting safety.

How Can Lifting Odd-Shaped or Fragile Loads Lead to Increased Risks?

Lifting odd-shaped or fragile loads leads to increased risks because these materials require specialized handling techniques to prevent structural damage and ensure worker safety. Pressure vessels up to 14,214 millimeters in length need customized lifting solutions to maintain structural integrity during transport.

Fragile materials present unique challenges:

- Bridge segments, precast concrete, and steel components require precise positioning to avoid stress fractures

- Materials unable to withstand inward pressure from standard slings face damage risk

- 45-foot long liquid nitrogen tanks require multiple custom-length spreader bars to prevent deformation

- Modular timber units and cable drums need specialized spreader configurations during lifts

These specialized requirements increase operational complexity and demand experienced rigging teams with appropriate equipment. The transition to addressing space constraints reveals additional challenges that compound lifting difficulties.

In What Ways Do Space Constraints and Clearance Issues Affect Lifting Procedures?

Space constraints and clearance issues affect lifting procedures by limiting equipment options and increasing operational risks in confined environments. The Mayfair Manoeuvre project required MultiPoint Lifts with only 2cm clearance to spare, demonstrating the precision demanded in tight spaces.

Key space-related challenges include:

- Spreader beams typically require more headroom than lifting beams, impacting confined space operations

- 100 crane-power line contacts occur annually in the US, with 20% of construction crane fatalities from power line contact

- Mobile cranes and tower cranes near roadways face high-risk operations due to utility infrastructure proximity

- Urban construction sites often require modular spreader systems adjusting spans from minimal to 100m/330 feet

These constraints force operators to select specialized equipment and implement additional safety measures. Proper spreader bar selection and configuration become essential solutions for overcoming these operational obstacles while maintaining safety standards.

How Do Spreader Bars Function to Address Lifting Difficulties?

Spreader bars function to address lifting difficulties by distributing loads across multiple points, maintaining proper sling angles, and protecting materials from crushing forces. These rigid steel beams solve critical challenges in heavy lifting operations through their specialized design and engineering.

What Is the Core Design and Purpose of a Spreader Bar in Lifting Applications?

Spreader bars are rigid steel beams that keep lifting slings at proper angles and prevent load crushing. They use two-leg slings under compressive forces, maintaining sling separation to protect loads from inward pressure that could cause damage or structural failure.

Design standards follow ASME BTH-1 for allowable stresses and ASME B30.20 for safety requirements. Each spreader bar requires a permanent rating plate showing manufacturer, capacity, and specifications per ASME B30.20 regulations. Structural integrity must withstand compressive forces with safety factors built into design per ASME BTH-1 standards, ensuring reliable performance under working loads.

How Do Spreader Bars Enhance Load Distribution and Minimize Damage?

Spreader bars create stable and controlled lifting environments through horizontal load distribution across multiple attachment points. This design prevents concentrated stress that can damage fragile materials or cause structural failure in sensitive components.

Optimal sling angles range from 75° to 90° for maximum load capacity. Load cells verify proper distribution during testing at 2x Working Load Limit for certification. According to Finite Element Analysis studies, spreader bars evenly distribute force on 80-ton pressure vessels, demonstrating their effectiveness for heavy industrial applications.

Why Are Adjustable and Custom Spreader Bars Important for Diverse Lifting Needs?

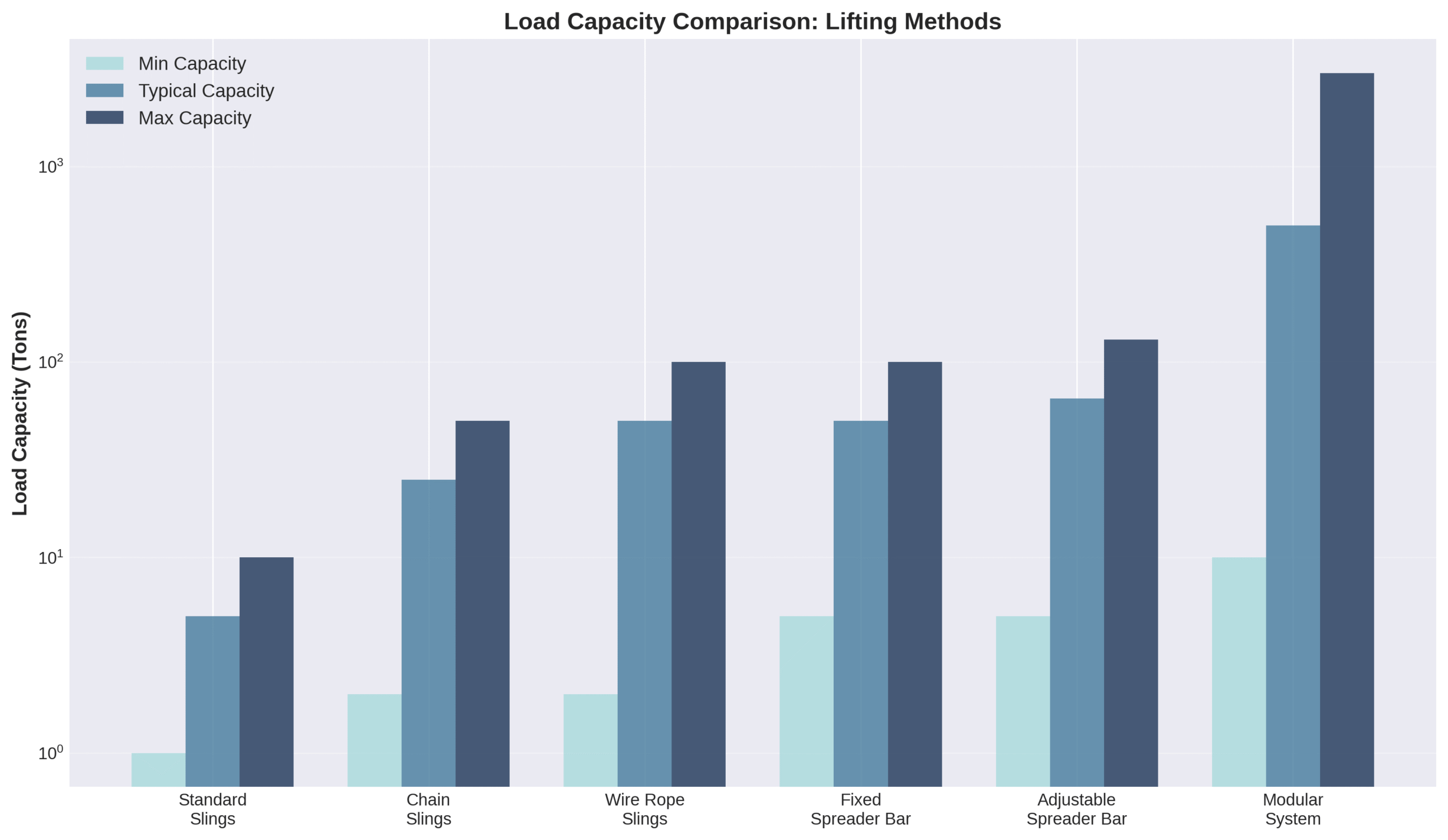

Fixed spreader bars handle 5 to 100 tons for repetitive lifts with consistent load dimensions. Adjustable spreader bars provide on-site span adjustment capability for variable load widths, accommodating different project requirements without equipment changes.

Modular systems like Modulift can handle up to 3000 tons with spans extending to 100m/330 feet. Custom spreader bars can include forklift tine pockets and universal crane hooks for versatility. Interchangeable components in modular systems allow quick configuration changes, reducing setup time and increasing operational efficiency across diverse lifting applications.

This section demonstrates how spreader bars solve fundamental lifting challenges through engineering innovation and standardized safety protocols. The next section examines critical safety considerations when implementing spreader bar solutions.

What Are the Safety Considerations When Using Spreader Bars for Lifting?

Spreader bars enhance lifting safety through systematic risk reduction, proper operational protocols, and regulatory compliance. These rigid steel beams create controlled lifting environments that address the primary causes of crane accidents and equipment failures. The following sections examine how spreader bars reduce accident risks, essential operational precautions, and compliance requirements that protect workers and equipment.

How Do Spreader Bars Reduce the Risk of Accidents and Equipment Failure?

Spreader bars reduce accident risks by automatically maintaining proper sling angles, eliminating the human error that causes 90% of crane accidents. The controlled horizontal distribution prevents load crushing and maintains optimal lifting geometry throughout operations.

Even weight distribution across multiple attachment points addresses critical failure modes. A 2003 analysis of 249 overhead crane incidents revealed 133 injuries and 133 fatalities that proper load distribution could have prevented.

Spreader bars eliminate the rigging failures responsible for 60% of crane-related fatalities according to CDC studies.

Key safety benefits include:

- Prevention of load drops through maintained sling geometry

- Reduced risk of workers being crushed by shifting loads

- Enhanced stability during lifts and positioning

- Anti-collision technologies in modern spreader systems

- Load-sensing capabilities that alert operators to weight distribution issues

Modern spreader systems integrate advanced safety technologies such as load monitoring sensors and collision avoidance systems that provide real-time feedback to operators.

What Precautions Should Be Taken When Selecting and Operating Spreader Bars?

Critical precautions begin with thorough visual inspection for damage, wear, and deformation before each use. Operators must hold NCCCO certification or meet OSHA qualified rigger requirements to ensure competent operation.

Load calculations must account for center of gravity positioning and verify total weight remains within equipment capacity limits. Pre-lift safety meetings with documented procedures represent essential best practice for complex lifting operations.

Essential operational precautions include:

- Daily inspection protocols covering structural integrity

- Verification of load weight and center of gravity

- Confirmation of proper sling angles and attachment points

- Environmental assessment for wind, weather, and clearance conditions

- Communication protocols between riggers, operators, and spotters

Inspection intervals cannot exceed one year maximum, with severe service conditions requiring monthly to quarterly inspections. Documentation of all inspections and maintenance activities ensures regulatory compliance and equipment reliability.

How Does Compliance With Industry Standards Impact Lifting Safety?

Industry standard compliance directly impacts lifting safety through mandatory design requirements, testing protocols, and operational procedures. OSHA 1926 Subpart CC mandates specific requirements for cranes and derricks in construction applications.

Custom-designed lifting accessories must undergo proof testing to 125% of rated load before initial use per OSHA regulations. EN 13155 European Standard requires proof testing and specifies structural integrity requirements for lifting accessories. The 2026 ASME B30.20 update addresses adjustable and modular spreader bars with enhanced safety provisions.

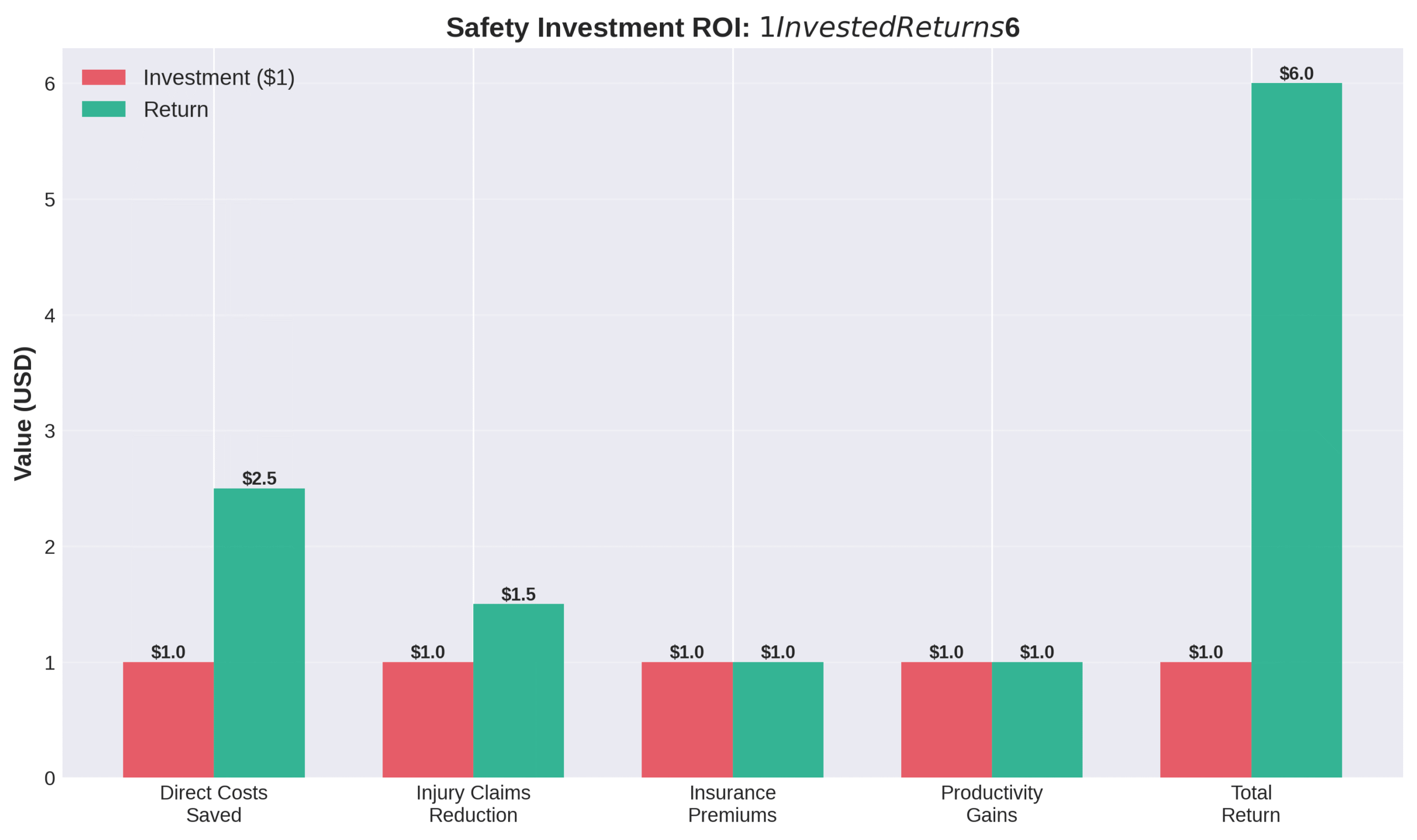

Compliance benefits extend beyond safety to economic returns. Studies demonstrate that $1 spent on workplace safety compliance saves up to $6 in direct and indirect costs through reduced accidents, insurance premiums, and productivity losses.

Standard compliance ensures proper design factors, testing protocols, and operational limits that protect both personnel and equipment throughout lifting operations.

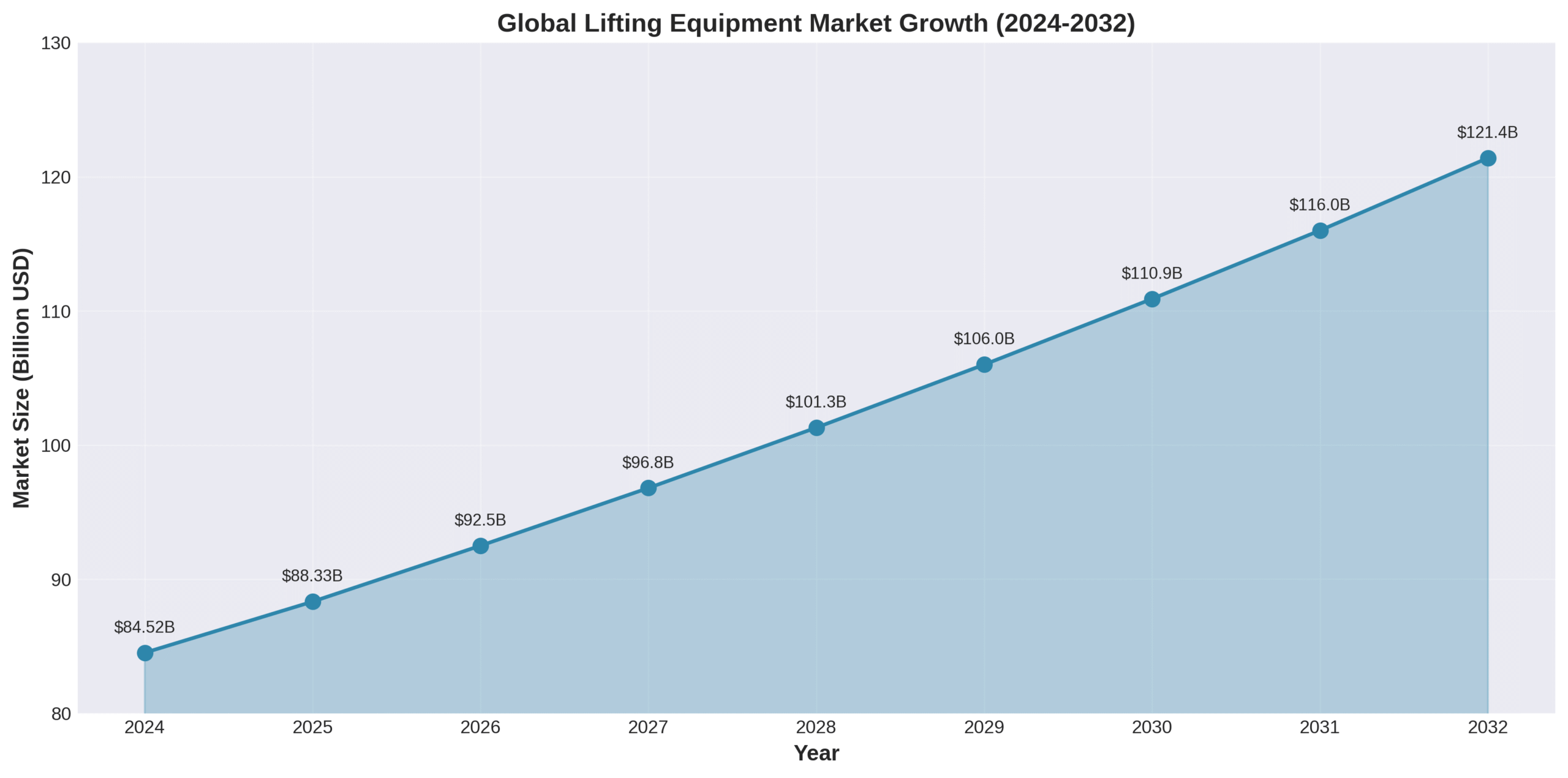

How Do Spreader Bars Compare to Other Lifting Solutions?

Spreader bars offer distinct advantages over alternative lifting methods through their compression-based design and distributed load support. The global lifting equipment market reached $84.52 billion in 2024, reflecting the critical importance of selecting optimal lifting solutions for industrial operations. This comparison examines spreader bars against lifting beams and other methods, evaluating performance factors, application scenarios, and cost considerations to guide equipment selection decisions.

What Are the Key Differences Between Spreader Bars and Lifting Beams?

The key differences between spreader bars and lifting beams center on force distribution mechanisms and operational configurations. Spreader bars use compression forces with multiple lift points while lifting beams use bending forces with single central hook attachment. This fundamental distinction affects performance characteristics across various lifting scenarios.

Structural and operational differences include:

- Force mechanics: Spreader bars operate under compression with distributed loads, while lifting beams handle bending moments through centralized support

- Headroom requirements: Lifting beams require lower headroom but spreader bars provide superior load distribution for elongated items

- Sling configuration: Spreader bars maintain adjustable sling angles while lifting beams utilize fixed vertical sling angles

- Load suitability: Spreader bars excel with long/fragile loads while lifting beams suit compact/heavy loads

Selection factors include headroom requirements, load characteristics, and lift configuration needs. These technical differences directly impact application effectiveness and operational safety in industrial lifting environments.

In Which Situations Are Spreader Bars a Better Choice Than Alternative Methods?

Spreader bars provide superior solutions for specific lifting scenarios requiring distributed support and load protection. Long loads requiring support at multiple points benefit from spreader bar’s distributed lifting capability, preventing structural deformation during transport.

Optimal spreader bar applications include:

- Fragile materials: Items that cannot withstand inward pressure from standard slings require spreader protection against crushing forces

- Wide objects: Equipment needing separation of lifting points utilizes spreader bars’ span adjustment capabilities

- Precision lifts: Operations requiring exact load positioning leverage spreader bars’ controlled distribution for accurate placement

- Container handling: Shipping container operations benefit from even weight distribution for safe loading/unloading processes

These applications demonstrate spreader bars’ effectiveness in protecting loads while maintaining operational control. The distributed force mechanism prevents damage that alternative lifting methods might cause through concentrated pressure points or inadequate support distribution.

How Do Cost and Efficiency Factor Into the Selection of Lifting Equipment?

Cost and efficiency considerations significantly influence lifting equipment selection decisions in industrial operations. The industrial rigging service market valued at USD 2.52 billion globally in 2024 reflects substantial investment in specialized lifting solutions. Economic factors include initial acquisition costs, operational efficiency gains, and risk mitigation savings.

Financial considerations include:

- Rental benefits: No capital investment required with included maintenance for project flexibility and reduced upfront costs

- Purchase advantages: Long-term savings for frequent use with equipment always available for immediate deployment

- Safety economics: Reduced injury costs save average of $43,000 per incident, with fatality prevention saving $1.46 million per occurrence

- Market growth: Projected market expansion to $88.33 billion in 2025 indicates increasing demand for efficient lifting solutions

These economic factors demonstrate that proper equipment selection delivers measurable returns through operational efficiency, safety improvements, and reduced liability exposure. Investment analysis should consider both direct equipment costs and indirect benefits from enhanced safety performance and operational reliability.

The comparison reveals spreader bars’ unique value proposition in specific applications while highlighting the importance of matching equipment capabilities to operational requirements for optimal cost-effectiveness and safety outcomes.

How Can You Optimize Your Lifting Operations With Tway Lifting’s Expertise and Solutions?

You can optimize your lifting operations with Tway Lifting through comprehensive spreader bar solutions that address critical safety challenges and operational inefficiencies. Tway Lifting specializes in reducing the 90% of crane accidents caused by human error while providing equipment that prevents the rigging failures responsible for 60% of crane fatalities.

What Services and Products Does Tway Lifting Offer to Overcome Lifting Challenges?

Tway Lifting offers spreader bar solutions designed to eliminate the pressure damage and load instability that plague heavy lifting operations. Tway Lifting provides spreader bar rentals with two-leg slings that protect loads from inward pressure while maintaining optimal sling angles between 75° and 90° for maximum load capacity.

Fixed spreader bars are available for repetitive lifts in the 5 to 100-ton capacity range, ensuring consistent performance for standardized operations. For variable applications, Tway Lifting offers adjustable spreader bars that accommodate different load widths and configurations without requiring multiple equipment purchases.

Modular spreader bar systems feature interchangeable components that allow custom configurations for complex lifting scenarios. These systems can handle capacities up to 3000 tons with spans extending to 100 meters. Basket type spreader bars provide specialized solutions for unique load requirements such as pressure vessels, bridge segments, and fragile materials that cannot withstand standard rigging forces.

All Tway Lifting spreader bars comply with ASME BTH-1 and ASME B30.20 standards, featuring permanent rating plates and proof testing to 125% of rated load capacity as required by OSHA regulations.

What Are the Key Takeaways About Common Lifting Challenges and How Spreader Bars Solve Them We Covered?

Human error causes 90% of crane accidents, but spreader bars reduce this risk through automatic sling angle maintenance that eliminates load planning mistakes. Rigging failures account for 60% of crane fatalities, while proper spreader bar use ensures load stability through even weight distribution across multiple attachment points.

The financial impact is significant: average injury costs of $43,000 and fatality costs of $1.46 million are preventable with proper spreader bar equipment. Spreader bars distribute weight evenly across multiple points, preventing the 27% of load drops attributed to poor rigging practices according to Konecranes analysis of 249 industrial crane incidents.

Compliance with OSHA, ASME, and EN standards through proper spreader bar use delivers a 6:1 return on investment in safety equipment. This ROI calculation factors in prevented injuries, reduced insurance costs, improved operational efficiency, and compliance with regulatory requirements that avoid costly penalties.

For optimal results, organizations should conduct pre-lift safety meetings, ensure NCCCO certified operators, and implement visual inspection protocols before each use to maximize the safety and efficiency benefits of spreader bar systems.