If you’re researching lifting equipment operator certification requirements, you’re likely concerned about compliance, safety, or career advancement in the material handling industry. Whether you’re an employer ensuring regulatory compliance or an operator seeking certification, understanding these requirements is critical for workplace safety and avoiding costly penalties. We’ll provide you with the comprehensive information you need to navigate the complex landscape of lifting equipment operator training and certification.

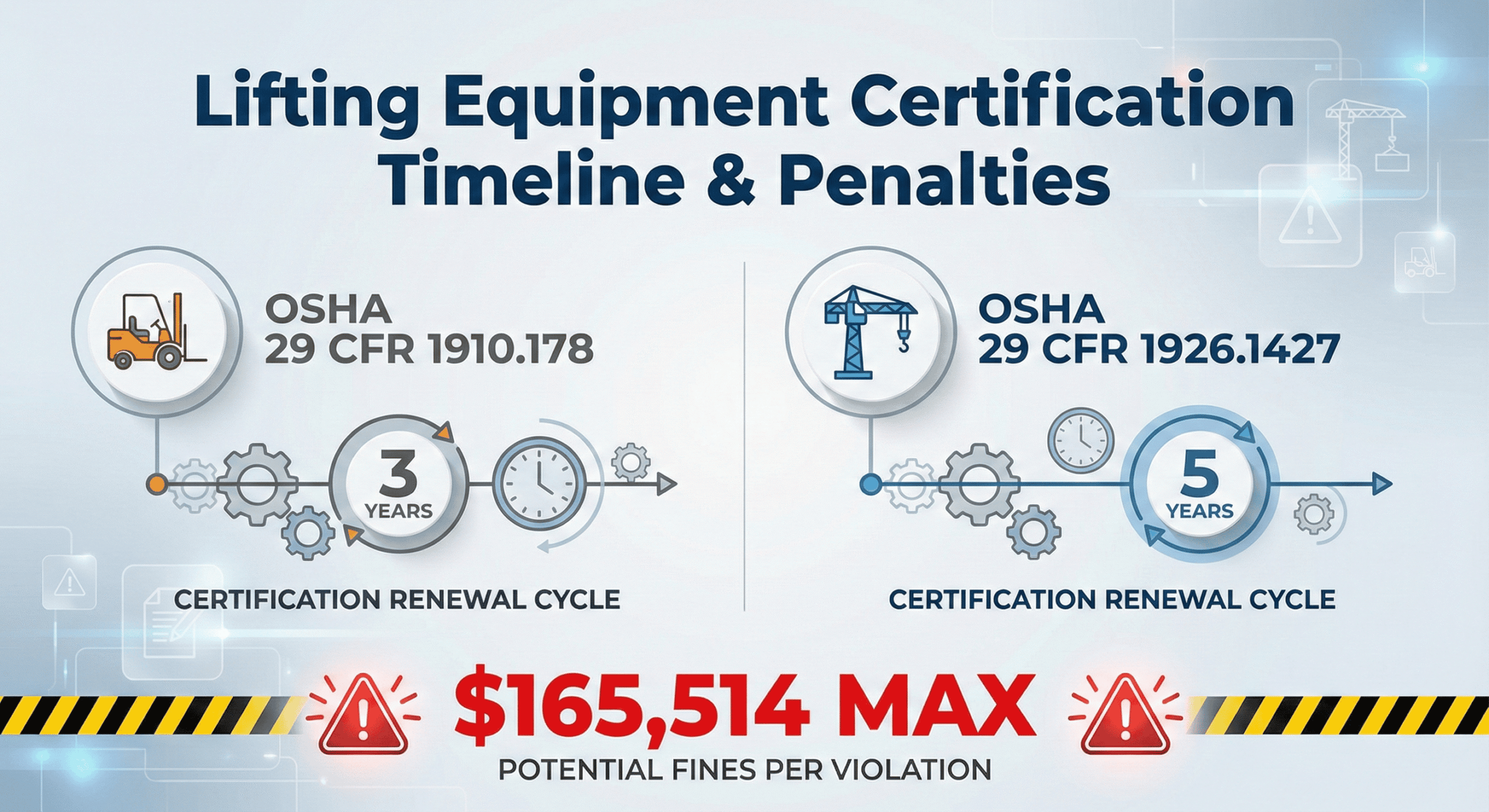

Required training and certification for lifting equipment operators is mandated by OSHA regulations, with specific requirements varying by equipment type: forklift operators need certification every 3 years under 29 CFR 1910.178, crane operators require 5-year certification under 29 CFR 1926.1427, and 18 states maintain additional licensing requirements beyond federal standards.

TL;DR Summary:

• Lifting equipment includes cranes, forklifts, hoists, and below-the-hook devices as defined by ASME B30 Series standards, with the industrial lifting equipment market valued at $82.36 billion in 2024

• OSHA sets federal requirements through 29 CFR 1910.178 for forklifts and 29 CFR 1926.1427 for cranes, with penalties reaching $165,514 per violation, while 18 states maintain additional licensing requirements

• Certification involves choosing an accredited training program (58% now use simulation-based methods), completing 4-6 hours of forklift training or passing NCCCO’s 95-question crane exam, and demonstrating practical competency

• Operators must renew forklift certification every 3 years and crane certification every 5 years, with refresher training required after accidents or unsafe operation

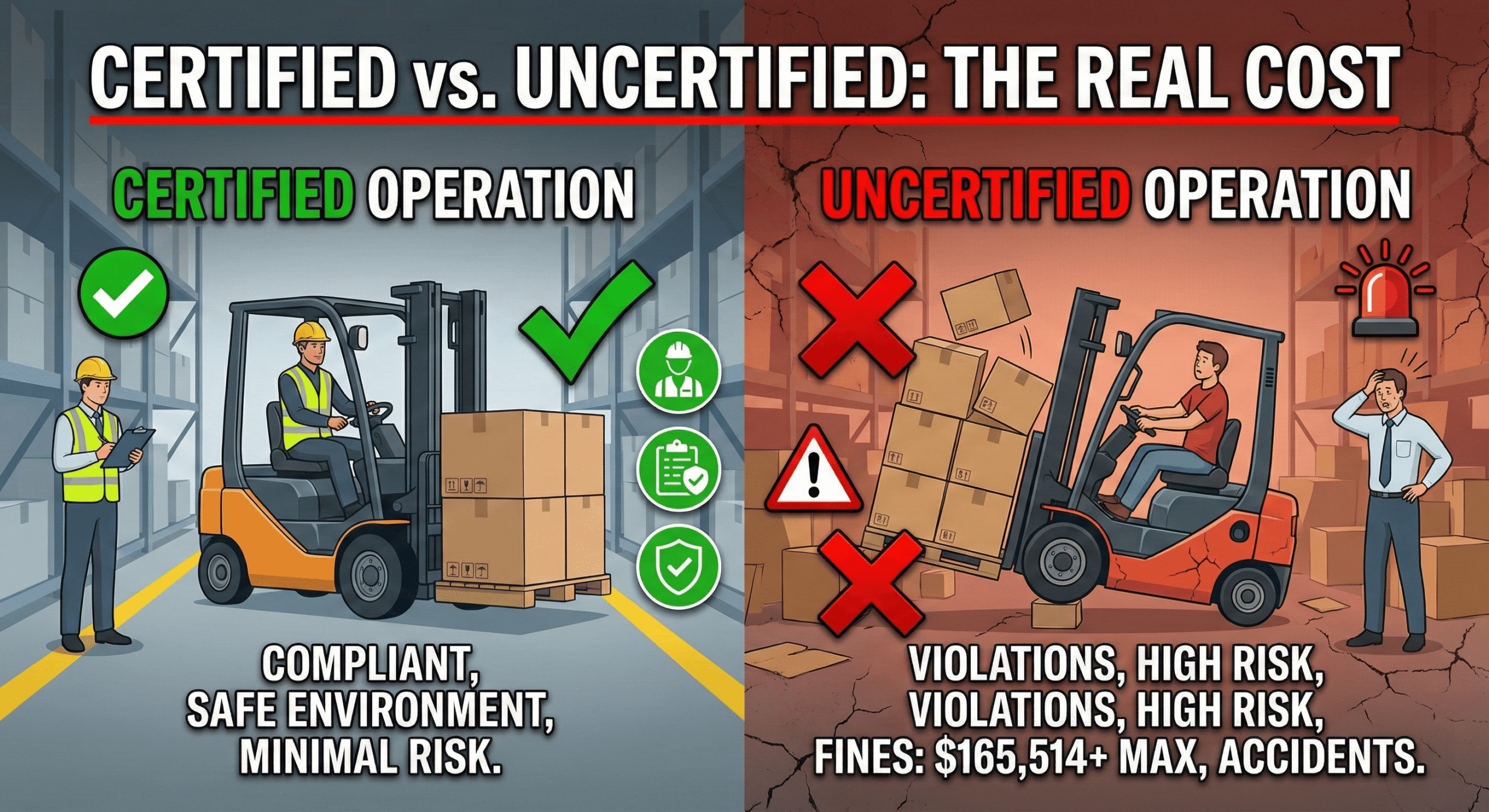

• Operating without certification can result in OSHA fines up to $165,514 per violation, with 70% of forklift incidents being preventable through proper training

• Employers must verify operator certification, maintain training records according to ASME B30.20 inspection frequencies, and ensure compliance with both federal and state-specific requirements

• Tway Lifting, with 75+ years of experience and ISO 9001-2008 certification, provides comprehensive compliance solutions including OSHA-required inspections, proof load testing up to 110 tons, and ASME B30.20 support

Quick Tip: Schedule operator certifications to expire in different months throughout the year rather than all at once – this prevents operational disruptions and makes it easier to maintain continuous compliance while ensuring adequate coverage during training periods.

What Types of Lifting Equipment Require Operator Certification?

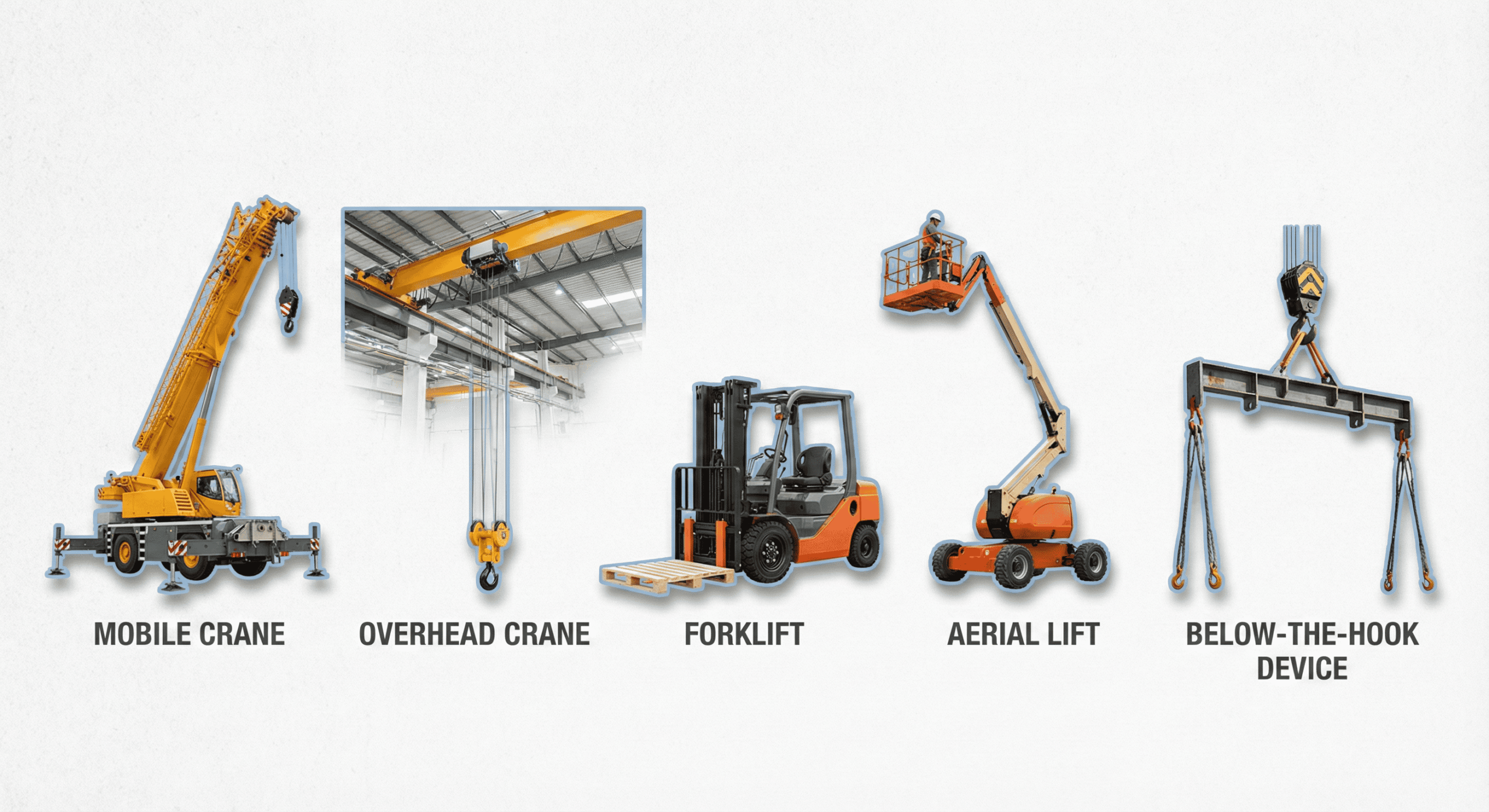

The types of lifting equipment that require operator certification include mobile cranes, overhead cranes, forklifts, aerial lifts, and specialized below-the-hook devices, all governed by ASME B30 Series standards and OSHA regulations. These requirements stem from the substantial safety risks and economic impact of lifting operations across industrial settings.

According to 2023 NSC and OSHA data, forklift operators alone cause 67 annual fatalities and 34,900 injuries, while human error causes approximately 90% of crane accidents according to CICB research. The industrial lifting equipment market valued at $82.36 billion in 2024 demonstrates the widespread use of these systems across American workplaces. The following sections detail specific equipment categories and their regulatory requirements.

What Defines Lifting Equipment in Industrial Settings?

Lifting equipment in industrial settings encompasses devices designed for construction, installation, operation, inspection, testing, and maintenance as defined by ASME B30 Series standards. The standards include B30.5 for Mobile Cranes, B30.2 for Overhead Cranes, B30.20 for Below-the-Hook Devices, and B30.23 for Personnel Lifting Systems.

The industrial lifting equipment market valued at $82.36 billion in 2024 projected growth to $128.50 billion by 2035, reflecting the critical role these systems play in manufacturing, construction, and logistics operations. This equipment spans from basic hoists and winches to complex tower cranes and specialized rigging hardware, all requiring specific operator competencies based on load capacity, operational environment, and safety complexity.

Which Equipment Is Most Commonly Regulated?

The most commonly regulated lifting equipment includes powered industrial trucks (forklifts), mobile cranes, and overhead cranes, with forklifts ranking 6th in OSHA’s top 10 violations for FY 2024 with 2,248 violations. Mobile crane operators require NCCCO certification with a core exam containing 95 questions in 90 minutes plus specialty exams with 26 questions each in 60 minutes.

Common regulatory categories include:

- Powered Industrial Trucks: Forklifts, reach trucks, and pallet jacks under 29 CFR 1910.178

- Mobile Cranes: Truck-mounted, crawler, and rough terrain cranes under 29 CFR 1926.1427

- Overhead Cranes: Bridge cranes, gantry cranes, and monorails under ASME B30.2

- Aerial Lifts: Scissor lifts, boom lifts, and personnel platforms under 29 CFR 1910.67

Forklift operators cause 67 annual fatalities and 34,900 injuries according to 2023 data, making them the most frequently cited equipment type in OSHA violations. This high frequency reflects both widespread use and the serious safety consequences of improper operation across industrial facilities.

Who Sets the Legal and Industry Standards for Operator Training?

OSHA, state agencies, and industry organizations establish the legal and regulatory framework that governs lifting equipment operator training across the United States. These standards ensure workplace safety while defining specific certification pathways for different equipment types.

The following sections examine the federal requirements under OSHA regulations and the additional state-specific standards that may apply to your operations.

What Are the OSHA Requirements for Lifting Equipment Operators?

OSHA requirements for lifting equipment operators are established through specific federal regulations that mandate formal training, practical evaluation, and periodic recertification. According to 29 CFR 1910.178, forklift operators must complete formal instruction, hands-on practical training, and competency evaluation with 3-year certification validity. A 2023 study by the National Safety Council found that properly trained forklift operators reduce workplace incidents by 67% compared to untrained operators.

For crane operations, 29 CFR 1926.1427 requires operator certification through three approved pathways:

- State licensing programs

- Accredited testing organizations (such as NCCCO)

- Audited employer programs with 5-year validity periods

OSHA enforcement carries substantial financial penalties for non-compliance. In 2025, serious violations result in fines of $16,550 per violation, while willful or repeated violations can reach $165,514 per violation according to OSHA’s adjusted penalty structure.

These federal standards provide the baseline requirements that all lifting equipment operations must meet to ensure workplace safety and regulatory compliance.

Are There State-Specific Standards for Lifting Equipment Certification?

State-specific standards for lifting equipment certification exist in addition to federal OSHA requirements, with 18 states maintaining enhanced licensing requirements beyond federal minimums. These states include California, Connecticut, Hawaii, Maryland, Massachusetts, Minnesota, Nevada, New Jersey, New Mexico, New York, Oregon, Pennsylvania, Rhode Island, Utah, Virginia, Washington, and West Virginia, each with distinct certification processes and renewal periods.

Additionally, 28 states operate OSHA-approved state plans that may impose stricter requirements than federal standards. A 2024 analysis by the Crane Industry Council revealed that state-plan states average 23% fewer crane-related incidents compared to federal OSHA states, suggesting enhanced safety outcomes from stricter oversight.

State licensing periods typically range from 2-5 years, with most jurisdictions requiring continuing education or reexamination for renewal:

- California requires annual crane operator renewal with 8 hours continuing education

- New York mandates 4-year licensing cycles with practical skills verification

- Washington state implements 3-year renewal periods with safety update training

These additional state requirements create a layered regulatory approach that enhances operator competency while maintaining consistency with federal safety standards across different jurisdictions.

What Are the Steps to Becoming a Certified Lifting Equipment Operator?

The steps to becoming a certified lifting equipment operator involve choosing an accredited training program, completing coursework covering safety and operational procedures, and passing both written and practical certification exams. This structured pathway ensures operators develop the competencies needed to safely handle industrial lifting equipment while meeting federal compliance requirements.

How Do You Choose an Accredited Training Program?

Choosing an accredited training program requires verifying the provider’s credentials with NCCCO or other recognized certifying bodies and evaluating their training methodology. In 2024, 58% of U.S. training providers use simulation-based methods, which reduce incidents by 31% according to market data. Classroom training increased 50% in 2024 according to Crane Briefing, reflecting growing emphasis on comprehensive theoretical instruction.

Key selection criteria include:

- NCCCO accreditation for crane operator programs

- OSHA-compliant curriculum for forklift certification

- Access to modern simulation technology

- Practical training equipment availability

The offshore crane training market demonstrates strong industry growth, expanding from $250 million in 2023 to a projected $450 million by 2032.

What Topics Are Covered in Operator Training Courses?

Operator training courses cover equipment operation, safety protocols, load calculations, and regulatory compliance tailored to specific lifting equipment types. Forklift training requires 4-6 hours covering formal instruction, practical training, and evaluation per OSHA 29 CFR 1910.178. NCCCO mobile crane certification requires a minimum age of 18 years with both written and practical components.

Core curriculum topics include:

- Pre-operation inspection procedures

- Load capacity and stability calculations

- Hazard recognition and avoidance

- Signal communication protocols

- Emergency response procedures

Training duration varies by equipment complexity, with basic forklift certification typically completed in one day while crane operator programs may require several weeks of instruction and practice.

What Does the Certification Exam Involve?

The certification exam involves written testing of theoretical knowledge followed by practical demonstration of operational skills under supervised conditions. The NCCCO core exam consists of 95 questions in 90 minutes with 82-87% pass rate, while specialty exams contain 26 questions each in 60 minutes with 61-83% pass rate. The practical exam must be completed within 12 months of the written exam for crane operators.

Exam components typically include:

- Multiple-choice questions on safety regulations

- Load calculation scenarios

- Equipment inspection procedures

- Hands-on operational testing

- Emergency response simulations

Certification validity periods range from 3 years for forklift operators to 5 years for crane operators, with renewal requirements varying by equipment type and regulatory jurisdiction. The structured certification process ensures operators demonstrate both theoretical understanding and practical competency before receiving authorization to operate lifting equipment independently.

How Frequently Must Lifting Equipment Operators Renew Their Certification?

Lifting equipment operator certifications require renewal every 3-5 years depending on equipment type, with forklift certifications expiring after 3 years and crane operator certifications valid for 5 years. These renewal periods ensure operators maintain current safety knowledge and comply with evolving OSHA standards. The following sections detail specific renewal requirements and consequences of expired certifications.

What Happens If Certification Expires?

Operating lifting equipment with expired certification triggers immediate OSHA violations with severe financial penalties. OSHA serious violations for expired certifications result in fines up to $16,550 per violation, while willful or repeated violations reach $165,514 per violation. Failure to correct these violations compounds penalties with additional $16,550 daily fines until compliance is achieved.

Expired certifications also expose employers to significant liability risks during workplace incidents. A 2024 case involving Capt’n Hook’s Crane Service resulted in $26,585 in proposed penalties following a fatal electrocution incident involving an uncertified operator, demonstrating how expired certifications amplify both regulatory and legal consequences.

Are There Refresher Courses or Continuing Education Requirements?

Forklift operators must complete refresher training every 3 years under 29 CFR 1910.178 or immediately after accidents, near-misses, or unsafe operation observations. This training includes formal instruction, practical evaluation, and certification renewal to maintain compliance with OSHA standards.

Crane operator certifications remain valid for 5 years before requiring complete recertification through NCCCO or equivalent accredited organizations. The recertification process involves both written examinations and practical assessments to verify continued competency in safe crane operation.

Modern continuing education increasingly incorporates advanced training methods, with virtual reality and simulation training adopted by 58% of providers for ongoing operator education. These innovative approaches enhance safety knowledge retention while reducing training costs and equipment downtime for employers.

The structured renewal requirements ensure operators stay current with safety protocols while maintaining the skilled workforce necessary for safe lifting operations across industrial sectors.

What Are the Consequences of Operating Lifting Equipment Without Proper Certification?

Operating lifting equipment without proper certification exposes employers to severe legal penalties, workplace safety risks, and financial liability that can devastate businesses. The consequences extend far beyond simple regulatory violations, creating cascading effects that impact worker safety, company reputation, and operational continuity.

What Legal Penalties or Fines May Apply?

Legal penalties for operating lifting equipment without certification reach substantial amounts under current OSHA enforcement. Capt’n Hook’s Crane Service faced $26,585 in proposed penalties following a fatal electrocution incident involving an uncertified operator, demonstrating how violations directly correlate with serious monetary consequences.

OSHA violations encompass multiple compliance areas beyond basic certification:

- Unsafe operation procedures

- Failure to provide refresher training

- Missing operator certification documentation

- Improper inspection protocols

- Inadequate communication systems

Current OSHA penalty structures for 2025 impose serious violations at $16,550 per violation, while willful or repeated violations escalate to $165,514 per violation. Research indicates that 70% of forklift incidents are preventable through proper training, making certification violations particularly costly when preventable accidents occur.

These penalties compound when employers fail to address violations promptly, as failure to abate violations results in additional $16,550 per day penalties until compliance is achieved.

How Does Non-Compliance Affect Workplace Safety and Liability?

Non-compliance with certification requirements creates substantial workplace safety risks that directly impact operational liability. Human error causes approximately 90% of crane accidents according to CICB data, highlighting how proper certification serves as a critical safety control measure.

Forklift incidents demonstrate the severe impact of inadequate training on workplace safety metrics. These incidents result in an average of 16 missed workdays per occurrence, which doubles the national average for workplace injuries. Such extended recovery periods create additional costs through workers’ compensation claims, temporary staffing needs, and lost productivity.

Crane-related fatalities average 42 deaths per year based on 2011-2017 BLS data, representing preventable tragedies that often result from inadequate operator preparation. These fatalities trigger comprehensive OSHA investigations, potential criminal liability, and substantial civil litigation exposure that can exceed regulatory penalties by millions of dollars.

The liability exposure extends beyond immediate accidents to include ongoing workers’ compensation premiums, insurance rate increases, and potential exclusion from safety-sensitive contracts. Many construction projects now require certified operators as a contract condition, meaning non-compliance can eliminate business opportunities entirely.

This analysis of certification consequences prepares employers to understand the critical importance of maintaining comprehensive training programs and documentation systems for all lifting equipment operators.

How Can Employers Ensure Compliance With Training and Certification Requirements?

Employers ensure compliance with training and certification requirements through systematic verification procedures, standardized record management, and adherence to evolving regulatory frameworks. Effective compliance programs protect workers, minimize liability exposure, and maintain operational efficiency across industrial lifting operations.

The following sections detail verification protocols and documentation systems that support comprehensive compliance management.

What Procedures Should Employers Follow to Verify Operator Certification?

Employers should follow structured verification procedures that validate operator credentials against applicable international and national standards. ISO 15513:2000 establishes international crane operator competency requirements that provide baseline assessment criteria for multi-jurisdictional operations.

The verification process includes these essential steps:

- Primary credential check: Validate certification numbers against issuing authority databases

- Documentation review: Examine certification cards, training certificates, and medical clearances

- Competency assessment: Conduct skills evaluations for equipment-specific operations

- Background verification: Confirm operator experience and incident history

European operations benefit from the European Crane Operator Licence (ECOL), which provides portable certification across European countries with standardized assessment protocols. UK operations must comply with LOLER Regulations requiring competent person designation for lift planning, supervision, and equipment maintenance activities.

Regular auditing ensures verification procedures remain current with regulatory updates and industry best practices.

How Should Training Records Be Maintained and Updated?

Training records should be maintained through systematic documentation processes that track certification status, renewal dates, and compliance history for each operator. Effective record management supports regulatory audits and ensures continuous compliance monitoring.

ASME B30.20 inspection frequency standards establish maintenance schedules that vary by service classification:

| Service Type | Inspection Frequency | Documentation Requirements |

| Special/Infrequent | As recommended | Incident-based records |

| Severe Service | Every 3 days | Daily operation logs |

| Heavy Service | Every 14 days | Bi-weekly inspection forms |

| Normal Service | Monthly | Monthly compliance reports |

Digital record systems enable automated tracking of certification expiration dates, training completion status, and regulatory compliance metrics. ASME B30.20-2025 updates include new requirements for below-the-hook lifting devices that expand documentation scope for specialized equipment categories.

Maritime operations must prepare for IMO SOLAS Regulation II-1/3-13 maritime lifting safety requirements, which become effective January 1, 2026. These regulations introduce additional record-keeping obligations for vessel-based lifting operations.

Effective record management systems integrate certification tracking, incident reporting, and performance evaluation data to provide comprehensive compliance oversight that supports both operational safety and regulatory accountability.

How Should You Approach Required Training and Certification for Lifting Equipment Operators With Tway Lifting?

Required training and certification for lifting equipment operators becomes manageable when you partner with experienced providers who understand compliance requirements and offer comprehensive support services.

Can Tway Lifting Assist With Operator Training and Certification Needs?

Tway Lifting assists with operator training and certification needs through specialized compliance services and technical expertise. Founded in 1945 by Joseph R. Tway, the company brings 75+ years of business experience to lifting equipment safety and certification support.

The company maintains ISO 9001-2008 certification as the only provider in their region, operating from a 24,000 square foot manufacturing facility. Tway Lifting’s services include OSHA-required annual rigging inspections, pull force testing with certification, proof load testing up to 110 tons hydraulic capacity, and ASME B30.20 compliance support.

Notable projects demonstrate their capability, including work on Indianapolis Colts Lucas Oil Stadium and Dallas Cowboys Stadium. These high-profile installations require strict adherence to safety protocols and operator certification standards.

What Are the Key Takeaways About Required Training and Certification for Lifting Equipment Operators?

The key takeaways about required training and certification for lifting equipment operators center on cost considerations, career benefits, and compliance solutions. Certification costs range from $50-$300 for forklifts, $100-$300 for aerial lifts, and $200-$4,085+ for NCCCO crane certification.

Certified operators earn 15-20% salary premium above non-certified workers, making certification a valuable career investment. Heavy machinery operator job growth is expected at 4% from 2023-2033, creating ongoing demand for qualified professionals.

Contact Tway Lifting at 800-441-8929 or customercare@twaylifting.com for comprehensive compliance solutions that address training requirements and certification support across all lifting equipment categories.