Description

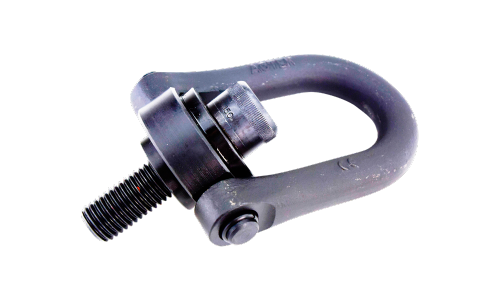

Actek Swivel Hoist Ring

Actek® Manufacturing & Engineering hoist rings are manufactured using AISI 4140 Aircraft Quality Chrome-Moly which meet or exceed ASTM A322. All of our 4140 material is metallurgically analyzed and certified. All of our Swivel hoist rings are heat treated to MIL-H-6875 and magnetic particle inspected to accordance with ASME Section 5, Article 7. Actek hoist rings meet or exceed all the requirements of ASME B30.26.

Actek swivel hoist rings include safety-engineered style, forged style, and stainless steel hoist rings. We offer different plating options also. Other swivel hoist rings include side load, flip-flop, mold-handler, speed base, round base, pivot plate hoist rings. Custom made hoist rings are also available to suit all of your lifting needs.

Each Actek hoist ring is 200% Proof-load tested and individually serial numbered for better trace-ability. Each hoist ring is individually packaged, shipped with a certificate of conformance, safety precaution, and additional safety information.

Swivel Hoist Rings are designed for lifting at any angle because they can swivel 360° and pivot 180°. Therefore, the rated load remains the same, regardless of the angle of force. As a result, you increase safety and peace of mind. Hoist rings are available with a rated load ranging from 800 lbs. to 250,000 lbs. with a 5:1 design safety factor.

We are currently approved and are selling swivel hoist rings to General Motors (GM), Chrysler, Ford, Boeing, General Electric (GE), Siemens-Westinghouse, Lockheed-Martin, NASA/Johnson Space Center, US Navy, US Army, major public utility companies, municipalities, naval shipyards and nuclear power generating facilities.