Are you tasked with managing heavy lifting operations in challenging marine environments? Whether you’re overseeing offshore wind turbine installations, subsea construction projects, or vessel-to-vessel transfers, understanding the critical role of spreader bars can mean the difference between operational success and costly failures. We’ll guide you through everything you need to know about these essential below-the-hook lifting devices that keep your marine operations safe and efficient.

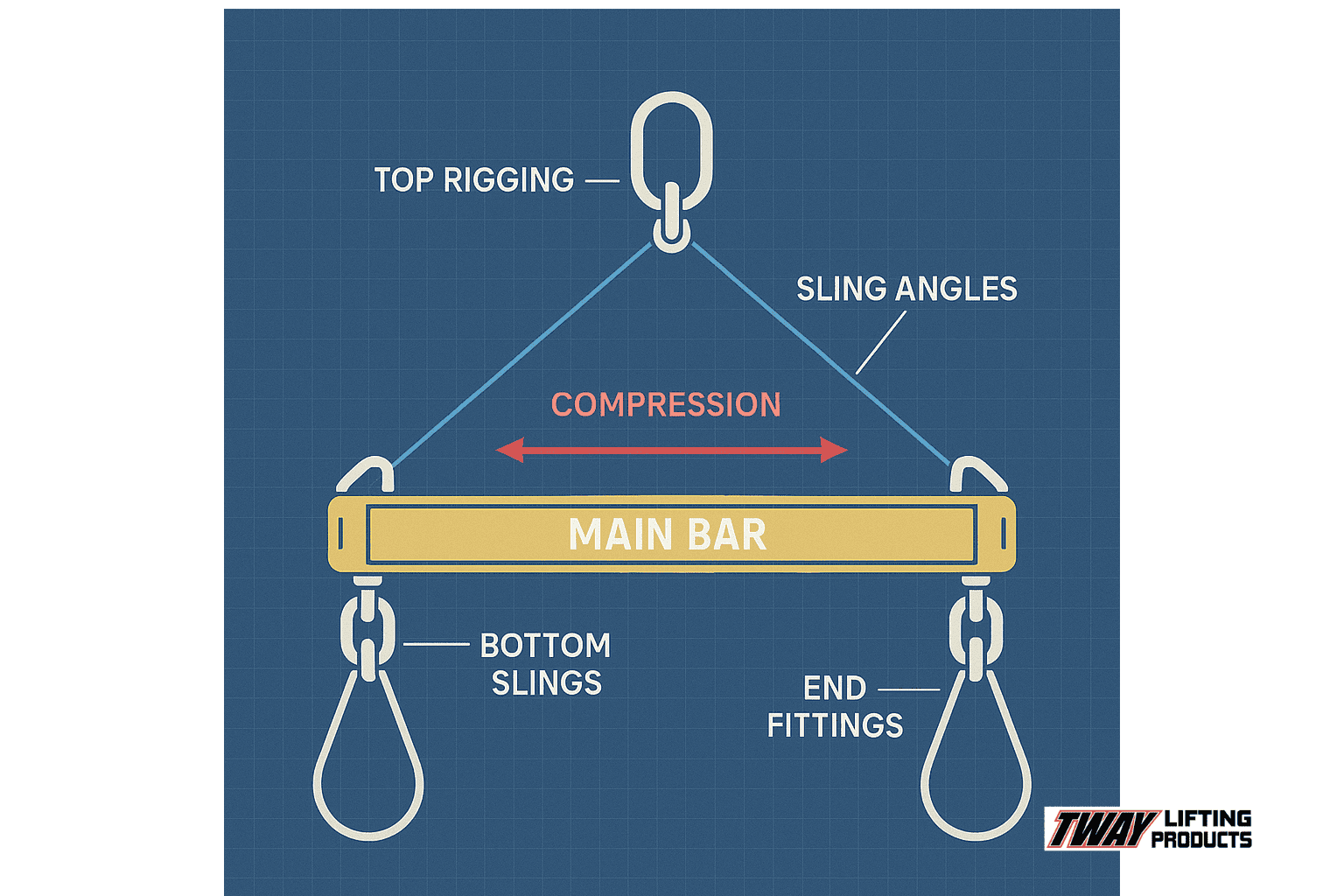

Spreader bars for offshore and marine lifting operations are specialized below-the-hook lifting devices that distribute the weight of heavy loads across multiple points by converting lifting forces into compression rather than bending stress. These engineered devices consist of a rigid bar or truss structure with end fittings that connect to slings, enabling safe handling of oversized loads in maritime environments while maintaining stability during complex lifts. In the demanding conditions of offshore operations, spreader bars serve as critical safety equipment that prevents load damage, reduces rigging stress, and ensures compliance with strict international safety standards.

TL;DR Summary:

- Function and Design: Spreader bars convert lifting loads into compressive forces, featuring main bodies, end fittings, and specialized rigging systems made from marine-grade materials with corrosion-resistant coatings.

- Safety Standards: Compliance with OSHA 29 CFR 1926.251, ASME B30.20, DNV certification, and ABS standards is mandatory, with proof testing at 125% capacity required for custom designs.

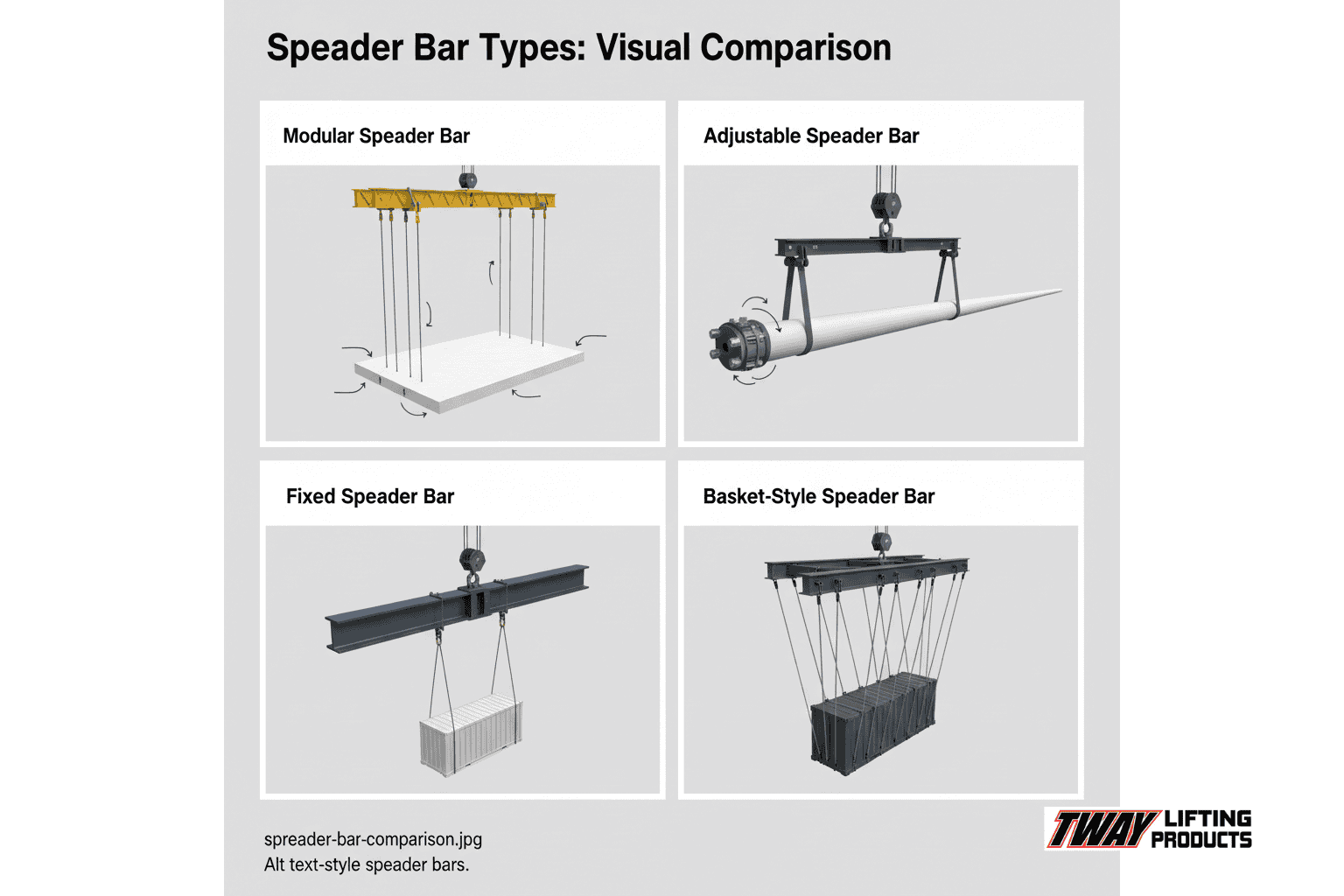

- Types and Applications: Fixed, adjustable, modular, and basket-style spreader bars serve different purposes from container handling to wind turbine installation, with capacities reaching up to 3,500 tonnes.

- Engineering Requirements: Critical load calculations, stress analysis per ASME BTH-1, and real-time monitoring systems ensure safe operation within design parameters.

- Best Practices: Daily pre-use inspections, maintaining 30-degree minimum sling angles, comprehensive lift planning, and proper storage with corrosion prevention are essential for safety.

- Real-World Applications: Major projects like the Woodside Scarborough Energy Project demonstrate 60% personnel reduction and 40% productivity gains using advanced spreader bar technology.

- Market Growth: The global spreader bar market is projected to reach USD 1,293 million by 2033, growing at 5.8% CAGR driven by offshore wind and subsea construction.

Quick Tip:

Always verify that your spreader bar’s sling angles remain at 30 degrees or greater during operation – this simple check ensures proper load distribution and prevents dangerous overloading conditions that account for the majority of lifting accidents.

As we explore the technical specifications, safety requirements, and emerging technologies in spreader bar applications, you’ll gain the knowledge needed to select, operate, and maintain these critical devices for your specific offshore lifting challenges.

How Do Spreader Bars Function in Offshore and Marine Lifting Applications?

Spreader bars function by converting lifting loads into compressive forces rather than bending stress, distributing weight across multiple points for enhanced stability during complex offshore lifts. According to industry projections, the global spreader bar market will reach USD 1,293 million by 2033, growing at a CAGR of 5.8% driven by offshore wind energy expansion and subsea construction demands. These devices serve as essential below-the-hook lifting equipment, providing critical safety and efficiency improvements in maritime environments that handle increasingly heavy and oversized loads.

The following sections examine the specific components, operational differences from other lifting equipment, and typical load applications that make spreader bars indispensable for offshore operations.

What Are the Main Components and Design Features of Spreader Bars?

The main components of spreader bars include the main body (long bar or truss structure), end fittings that connect to slings, top rigging with slings connecting the bar to crane hooks, and bottom rigging that connects the bar to loads. Marine-grade materials feature high-strength steel alloys with specialized coatings, 316 stainless steel for saltwater exposure, and aluminum alloys for lightweight applications requiring reduced load capacity.

Corrosion prevention methods include epoxy coatings, galvanization, and thermal sprayed aluminum (TSA) to extend service life in harsh marine conditions. These protective treatments are essential given the constant exposure to saltwater, extreme temperatures, and high humidity characteristic of offshore environments.

How Do Spreader Bars Differ from Lifting Beams in Marine Environments?

Spreader bars differ from lifting beams by handling compressive forces while lifting beams are subject to bending stress, making spreader bars more suitable for certain marine applications requiring load distribution across multiple points. Spreader bars typically use slings at angles to create compression, whereas lifting beams have attachment points directly below for vertical lifting operations.

This fundamental difference in force distribution makes spreader bars ideal for loads requiring enhanced stability and control during complex offshore positioning operations.

What Types of Lifting Loads Are Commonly Managed with Spreader Bars in Offshore Settings?

The types of lifting loads commonly managed with spreader bars include container handling using fixed spreader bars with unchangeable length for repetitive identical loads, and construction applications using adjustable telescoping or modular designs for various load sizes. Pipe laying operations utilize basket-style spreader bars with four or more attachment points for flexible material handling, while wind turbine foundation installation employs specialized bars handling monopiles up to 3,500-tonne capacity.

These applications demonstrate the versatility of spreader bar designs in addressing specific offshore lifting challenges across multiple industry sectors.

This examination of spreader bar functionality establishes the foundation for understanding the safety standards and regulatory requirements that govern their use in offshore environments.

What Safety Standards and Regulations Govern the Use of Spreader Bars in Offshore and Marine Environments?

Safety standards and regulations for spreader bars in offshore and marine environments require compliance with international and regional codes to prevent lifting accidents. According to the Crane Inspection & Certification Bureau, 90% of lifting accidents trace back to inadequate pre-use inspections or human error in following established protocols, making regulatory compliance essential for all lifting equipment in offshore and marine operations.

The regulatory framework includes OSHA requirements for domestic operations, ASME standards for equipment design and operation, and international certifications from DNV and ABS for offshore projects. These standards work together to ensure equipment integrity, operational safety, and personnel protection in challenging marine environments.

What Are the Key OSHA and ASME Requirements for Spreader Bars in the US?

The key OSHA and ASME requirements for spreader bars include mandatory inspection protocols, proof testing standards, and operational safety guidelines. OSHA 29 CFR 1926.251 mandates inspection of all rigging equipment before each shift and proof testing of custom-designed lifting accessories at 125% rated capacity before initial use.

ASME standards provide comprehensive safety requirements through multiple specifications:

- ASME B30.20 provides detailed safety requirements for below-the-hook lifting devices including marking, inspection, construction, and operation protocols

- ASME BTH-1 specifies design criteria for lifting devices used in marine and offshore applications

- Sling angle requirements mandate maintaining angles at 30 degrees or greater to ensure proper load distribution and prevent overloading

These requirements establish baseline safety protocols for all spreader bar operations in US waters and facilities.

How Do Certification and Inspection Processes Work for Marine Lifting Equipment?

Certification and inspection processes for marine lifting equipment involve multiple organizations providing specialized oversight for offshore operations. DNV provides certification for offshore lifting equipment ensuring compliance with DNVGL-ST-0378 and DNV-SE-0480 standards, often required for international waters, while ABS offers Guide for Certification of Lifting Appliances with CRC (Crane and Lifting Appliances) class notation for certified equipment.

Daily operational inspections are mandatory and must be performed by qualified personnel who check welds, attachment points, and all rigging components for wear, damage, or deformation. These inspections complement the formal certification process by ensuring ongoing equipment integrity throughout service life.

The certification process typically includes design review, manufacturing oversight, testing verification, and periodic recertification to maintain validity in offshore operations.

Which Types of Spreader Bars Are Best Suited for Offshore and Marine Lifting?

Offshore and marine lifting operations require specialized spreader bars designed to withstand harsh maritime environments while maintaining strict safety standards. The selection depends on application requirements, environmental conditions, and material specifications that ensure reliable performance in saltwater exposure and extreme weather conditions.

What Are the Differences Between Modular, Adjustable, and Fixed Spreader Bars?

Fixed spreader bars maintain unchangeable length for repetitive lifts of identical loads. These designs excel in container handling and production line operations where consistent dimensions reduce setup time and improve operational efficiency.

Adjustable spreader bars feature telescoping mechanisms that modify length for various load sizes. Construction and general rigging applications benefit from this flexibility, allowing operators to handle diverse cargo with a single piece of equipment.

Modular spreader bars assemble from interchangeable components, creating various lengths and capacities. Heavy lifting and complex rigging configurations utilize these systems when standard equipment cannot accommodate unique load requirements.

Basket-style spreader bars incorporate four or more attachment points for long or irregularly shaped loads. Pipe laying operations rely on these multi-point systems to distribute forces evenly across extended payloads.

These configurations prepare operators for selecting equipment based on environmental challenges that directly impact material performance and longevity.

How Do Environmental Factors Influence Spreader Bar Selection for Marine Applications?

Equipment must withstand saltwater corrosion, extreme temperatures, and high humidity characteristic of marine environments. These conditions accelerate material degradation and require specialized protection systems to maintain structural integrity.

Material selection depends on exposure levels, with 316 stainless steel preferred for direct saltwater contact due to its superior corrosion resistance properties. Carbon steel components require additional protective treatments when exposed to marine atmospheres.

Protective coatings and treatments are selected based on environmental severity and expected service life. Thermal sprayed aluminum (TSA), epoxy systems, and galvanization provide varying levels of protection depending on application duration and exposure intensity.

Temperature fluctuations from -40°F to 120°F in offshore environments affect material properties and joint tolerances. Wind speeds exceeding 50 mph create dynamic loading conditions that influence spreader bar design and operational procedures.

Understanding environmental requirements leads directly to material specifications that ensure equipment reliability throughout its service life.

What Materials Are Commonly Used in Manufacturing Spreader Bars for Offshore Use?

Marine-grade high-strength steel alloys provide durability and load-bearing capacity with specialized anti-corrosion coatings. These materials offer tensile strengths exceeding 80,000 psi while maintaining ductility required for dynamic loading conditions in offshore applications.

316 stainless steel offers excellent corrosion resistance for components directly exposed to saltwater environments. This austenitic steel contains 2-3% molybdenum, providing superior pitting resistance compared to standard 304 grades in chloride environments.

| Material | Tensile Strength | Corrosion Resistance | Weight Factor | Primary Application |

| High-Strength Steel | 80,000+ psi | Good with coating | 1.0 | Heavy lifting operations |

| 316 Stainless Steel | 75,000 psi | Excellent | 1.0 | Saltwater exposure |

| Aluminum Alloy | 45,000-70,000 psi | Good | 0.35 | Weight-critical applications |

| Duplex Stainless | 90,000+ psi | Superior | 1.0 | Extreme environments |

Aluminum alloys provide lightweight alternatives with potentially lower load capacities than steel options. These materials reduce crane capacity requirements and improve handling efficiency, though design modifications may be necessary to maintain equivalent load ratings.

The combination of proper material selection with appropriate environmental protection ensures spreader bars deliver reliable performance throughout demanding offshore and marine lifting operations.

How Should Spreader Bars Be Engineered and Rated for Offshore Lifting Operations?

Spreader bars for offshore lifting operations require rigorous engineering analysis and capacity rating to ensure safe performance in demanding marine environments. The engineering process encompasses load calculations, stress analysis, and certification procedures that meet international safety standards for offshore equipment.

What Are the Critical Load Calculations and Capacity Considerations?

Critical load calculations for offshore spreader bars include working load limits, safety factors, and dynamic load considerations specific to marine environments. Custom-designed lifting accessories must undergo proof testing at 125% of rated capacity before initial use per OSHA requirements. Load monitoring systems with integrated load cells provide real-time data preventing overloads during lifting operations. Spreader bars with capacities up to 100 tons and spans up to 40 feet are available for rental from major manufacturers.

Engineers calculate static loads, dynamic amplification factors from wave motion, and wind loads that affect lifting operations offshore. The safety factor typically ranges from 4:1 to 6:1 for offshore applications, accounting for harsh environmental conditions and potential load variations during marine operations.

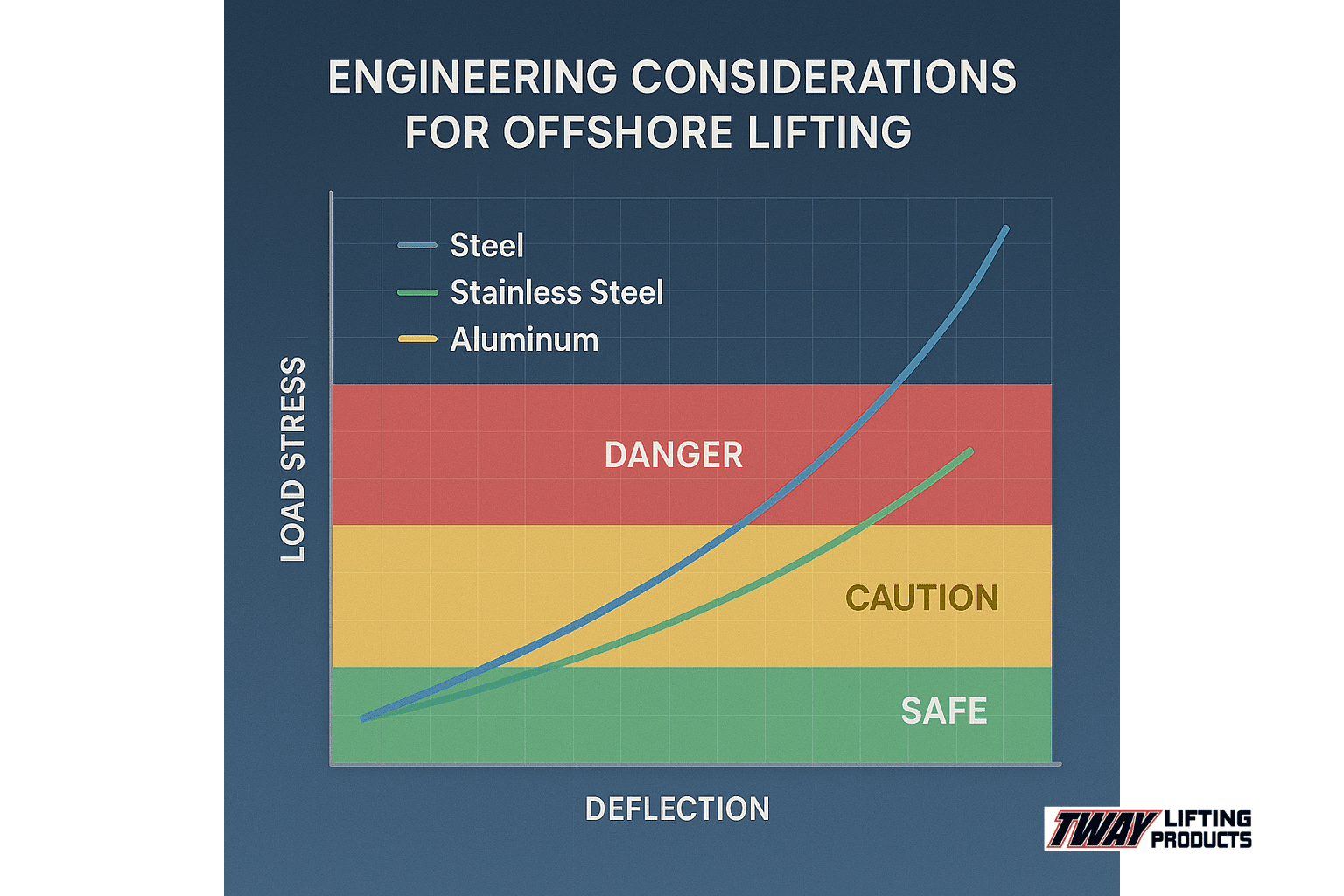

How Do Engineers Assess Stress, Deflection, and Fatigue in Spreader Bars?

Engineers assess stress, deflection, and fatigue through comprehensive finite element analysis and testing protocols mandated by marine certification bodies. ASME BTH-1 specifies design criteria including stress analysis requirements for lifting devices. DNV certification processes include detailed engineering assessments of stress, deflection, and fatigue life for offshore equipment. IoT-enabled sensors allow for real-time monitoring of equipment health and predictive maintenance to prevent failures.

Stress analysis considers maximum allowable stress limits, fatigue resistance for cyclic loading, and deflection limits that maintain proper sling geometry. Engineers evaluate material properties under marine conditions, including temperature variations, corrosion effects, and impact loading from vessel motion during offshore operations.

The engineering and rating process ensures spreader bars meet stringent offshore safety requirements while providing reliable performance in challenging marine environments. This comprehensive approach to design and certification establishes the foundation for safe lifting practices in offshore and marine operations.

What Are the Best Practices for Safe Rigging, Operation, and Maintenance of Spreader Bars Offshore?

Best practices for safe rigging, operation, and maintenance of spreader bars offshore include comprehensive lift planning, proper sling angle maintenance, routine inspections, and predictive maintenance protocols. Comprehensive lift plans must be developed for all critical lifts identifying potential hazards and outlining clear procedures. Maintaining proper sling angles of 30 degrees or greater ensures correct load distribution and prevents equipment overloading. Following these guidelines becomes especially critical in marine environments where environmental factors amplify safety risks.

What Are the Recommended Procedures for Inspecting Spreader Bars Before Use?

The recommended procedures for inspecting spreader bars before use require daily inspections by qualified personnel, comprehensive component checks, and systematic record-keeping. Daily inspections by qualified personnel are crucial to identify signs of wear, damage, or deformation in equipment. Inspection must include checking welds, attachment points, and all rigging components before each shift per OSHA regulations. RFID lifecycle tracking systems help maintain inspection records and schedule maintenance activities.

Critical inspection points include:

- Visual examination of welds for cracks or deterioration

- Load-bearing attachment points for signs of stress or wear

- Sling connection hardware for proper function

- Corrosion indicators on metal surfaces

How Should Spreader Bars Be Stored and Maintained to Prevent Corrosion and Damage?

Spreader bars should be stored and maintained through protective coatings, controlled environmental conditions, and predictive maintenance systems to prevent corrosion and damage. Epoxy coatings, galvanization, and thermal sprayed aluminum (TSA) are common corrosion prevention methods for marine environments. Equipment should be stored in dry conditions when possible and regularly treated with appropriate protective coatings. Predictive maintenance using IoT sensors reduces downtime and prevents failures through early detection of issues.

| Material / Condition | Specification | Performance / Requirement |

| Epoxy Coatings | Application Method | Spray or brush application |

| Galvanization | Protection Duration | 15-25 years in marine conditions |

| TSA Coating | Corrosion Resistance | Superior saltwater protection |

| Storage Environment | Humidity Level | <50% relative humidity preferred |

What Are the Most Common Hazards or Failures Associated with Spreader Bars in Marine Lifting?

The most common hazards or failures associated with spreader bars in marine lifting include uncontrolled equipment movement, inadequate inspection protocols, and improper load distribution. Uncontrolled movement of spreader bars during lifting operations poses significant risks as documented in IMCA safety flash incidents. Inadequate pre-use inspections account for a significant portion of lifting accidents according to industry safety data. Improper sling angles and load distribution can lead to equipment overloading and structural failure.

Primary failure modes include:

- Structural fatigue from repeated loading cycles

- Corrosion-induced weakening of critical components

- Human error in rigging configuration

- Environmental loading from wind and wave action

These best practices establish the foundation for successful offshore lifting projects by prioritizing safety through systematic planning, inspection, and maintenance protocols that address the unique challenges of marine environments.

What Are Common Applications and Real-World Examples of Spreader Bars in Offshore and Marine Operations?

Common applications for spreader bars in offshore and marine operations span three primary sectors. Offshore wind energy sector expansion drives demand for specialized spreader bars handling turbine components and foundations. Subsea construction projects require spreader bars for pipeline installation and underwater structure placement. Decommissioning of aging offshore platforms utilizes spreader bars for safe removal of heavy platform components. These applications demonstrate how spreader bars enable complex lifting operations in challenging marine environments where conventional lifting methods prove inadequate.

The following subsections examine specific use cases and documented project successes that showcase spreader bar capabilities in real-world offshore operations.

How Are Spreader Bars Used in Subsea Installations and Vessel-to-Vessel Transfers?

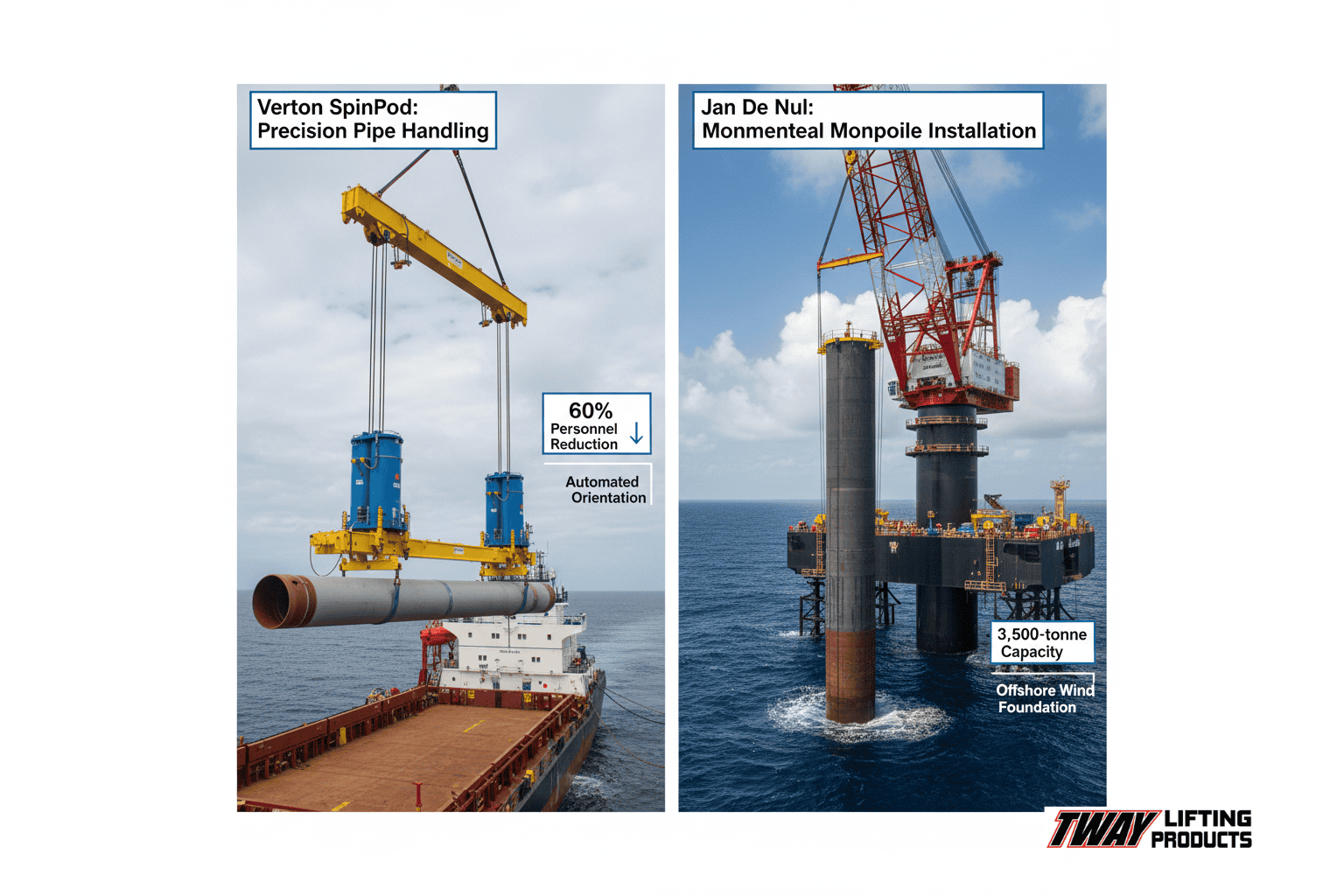

Spreader bars in subsea installations and vessel-to-vessel transfers incorporate advanced stabilization and automation technologies. Gyroscopic stabilization systems like Verton’s SpinPod provide rotational control without taglines, improving safety in vessel-to-vessel transfers. Automated pipe spreaders control orientation of pipeline sections during loading operations on offshore vessels. Spreader bars with automated sling handling reduce personnel required on deck during hazardous marine operations.

These applications address critical challenges in marine environments where vessel motion, weather conditions, and personnel safety create complex operational constraints that traditional lifting methods cannot adequately manage.

Can You Provide Case Studies of Successful Offshore Lifting Projects Using Spreader Bars?

Documented case studies demonstrate significant operational improvements through specialized spreader bar implementations. The Woodside Scarborough Energy Project (USD 12.5 billion) used Verton SP30 SpinPods on automated pipe spreaders for 250+ km of pipeline, reducing personnel requirements by 60% and exceeding transfer rates by 40%. Jan De Nul offshore wind farm installation employed a 3,500-tonne monopile spreader bar designed by Huisman for the largest turbine foundations in the industry. Projects using load monitoring systems like Modulift’s Active Link demonstrate real-time data logging preventing overloads in critical offshore lifts.

These case studies illustrate how proper spreader bar selection and implementation deliver measurable improvements in safety, efficiency, and project economics across diverse offshore applications, establishing best practices for future marine lifting operations.

How Should You Approach Offshore and Marine Lifting Projects with Tway Lifting?

Approaching offshore and marine lifting projects requires specialized expertise and equipment designed for harsh marine environments. Tway Lifting provides comprehensive solutions from custom engineering to certified equipment rental for complex maritime operations. The following sections detail how Tway Lifting supports offshore projects and summarize key considerations for spreader bar selection in marine applications.

How Can Tway Lifting Help with Spreader Bar Selection and Custom Solutions?

Tway Lifting helps with spreader bar selection through seven decades of specialized experience and ISO 9001 certification. The company provides DNV GL certified equipment specifically engineered for offshore project demands.

Tway Lifting offers spreader bars for rental with these capabilities:

- Capacities up to 100 tons for heavy offshore lifting

- Spans extending to 40 feet for wide load distribution

- Full compliance with ASME B30.20 and OSHA standards

- Certified inspection services with detailed documentation

The company’s 24,000 square foot Indianapolis manufacturing plant produces USA-made equipment with full-service capabilities. Their comprehensive solutions include custom engineering, certified manufacturing, and RFID lifecycle tracking for complete project visibility.

Tway Lifting’s product line encompasses modular, adjustable, and telescopic spreader bar models. These designs accommodate various offshore applications from container handling to subsea installations, providing flexibility for diverse marine lifting requirements.

What Are the Key Takeaways About Spreader Bars for Offshore and Marine Lifting Operations We Covered?

The key takeaways about spreader bars for offshore and marine lifting operations center on market growth, regulatory compliance, technological advancement, and material selection.

The offshore spreader bar market demonstrates strong growth trajectory from USD 765 million in 2024 to USD 1,293 million by 2033 at 5.8% CAGR. This expansion reflects increasing offshore wind energy development and subsea construction activities requiring specialized lifting equipment.

Regulatory compliance remains mandatory across multiple standards:

- OSHA 29 CFR 1926.251 for rigging equipment inspection

- ASME B30.20 for below-the-hook lifting device safety

- DNV and ABS certification for international offshore operations

- Proof testing at 125% capacity required for custom designs

Emerging technologies transform offshore lifting operations through IoT sensors enabling predictive maintenance, gyroscopic stabilization systems eliminating taglines, and wireless load monitoring preventing equipment overloads. These innovations enhance safety while reducing operational complexity.

Material selection prioritizes corrosion resistance with marine-grade steel, 316 stainless steel for saltwater exposure, and protective coatings including epoxy, galvanization, and thermal sprayed aluminum. Proper material selection extends equipment longevity in harsh marine environments while maintaining structural integrity throughout service life.

These considerations guide successful offshore lifting projects from initial planning through equipment selection and operational execution.