If you’re searching for information about modular spreader bars, you’re likely facing a lifting challenge that requires flexibility, safety, and cost-effectiveness. Whether you’re managing complex construction lifts, handling varied loads in manufacturing, or dealing with space constraints in transport and storage, we understand the critical decisions you’re making about lifting equipment. You’re in the right place to discover how modular spreader bars can transform your lifting operations with their unique adaptability and proven safety record.

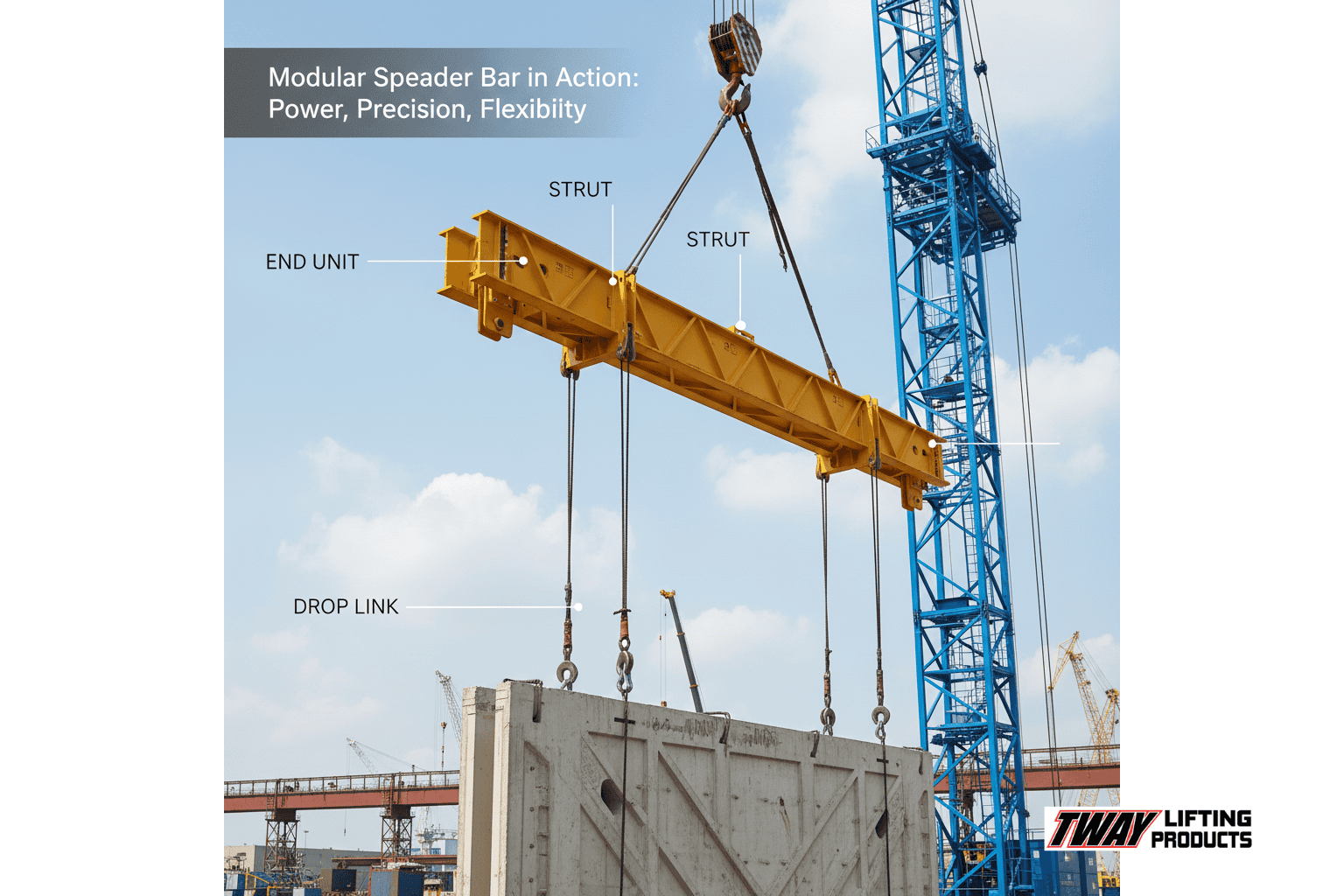

Modular spreader bars are versatile below-the-hook lifting devices consisting of interchangeable components—end units, struts, and drop links—that bolt together to create customized lifting configurations for various load sizes and spans. Unlike fixed spreader bars designed for repetitive identical lifts, modular systems offer remarkable flexibility by allowing on-site reconfiguration to handle capacities from 2 to 3,000 tonnes and spans extending up to 100 meters, making them invaluable when projects demand adaptability and when one system must replace multiple fixed beams for enhanced operational efficiency.

TL;DR Summary: We’ll explore the fundamental components and assembly processes that make modular spreader bars uniquely adaptable, including how end units, struts, and drop links work together with capacities ranging from 2 to 3,000 tonnes. You’ll discover when modular systems outperform fixed alternatives, particularly in precision lifting scenarios, multi-configuration projects, and industries like construction, oil & gas, and wind energy where flexibility is paramount. We’ll examine the key benefits including IoT integration, real-time monitoring capabilities, and compact storage advantages, while addressing critical limitations such as assembly time requirements and the 90% human error factor in crane accidents. You’ll learn essential selection criteria including load capacity calculations, environmental factors, and the three-tiered inspection system mandated by ASME B30.20 standards. Finally, we’ll show how partnering with experienced providers like Tway Lifting, established since 1945, ensures access to certified equipment, expert guidance, and nationwide support for your modular lifting needs.

Quick Tip: Always verify the total weight of your modular spreader bar assembly (including all struts, end units, and drop links) when calculating crane capacity requirements—the modularity that provides flexibility also adds weight that must be accounted for in your lift planning.

The foundation of safe and efficient lifting operations lies in understanding not just what equipment to use, but when and how to deploy it effectively. As we delve deeper into the technical specifications, safety standards, and practical applications of modular spreader bars, you’ll gain the knowledge needed to make informed decisions that protect your workers, optimize your operations, and ensure project success. The versatility of modular systems represents more than just technical innovation—it’s a fundamental shift in how we approach the diverse lifting challenges of modern industry.

What Are Modular Spreader Bars and How Do They Work?

Modular spreader bars are configurable lifting devices that distribute crane loads across multiple points through interchangeable components. These systems bolt together on-site to create custom spans and capacities for specific lifting operations.

The following sections explore the key components, assembly processes, and design specifications that make modular spreader bars essential for complex lifting operations.

What Components Make Up a Modular Spreader Bar System?

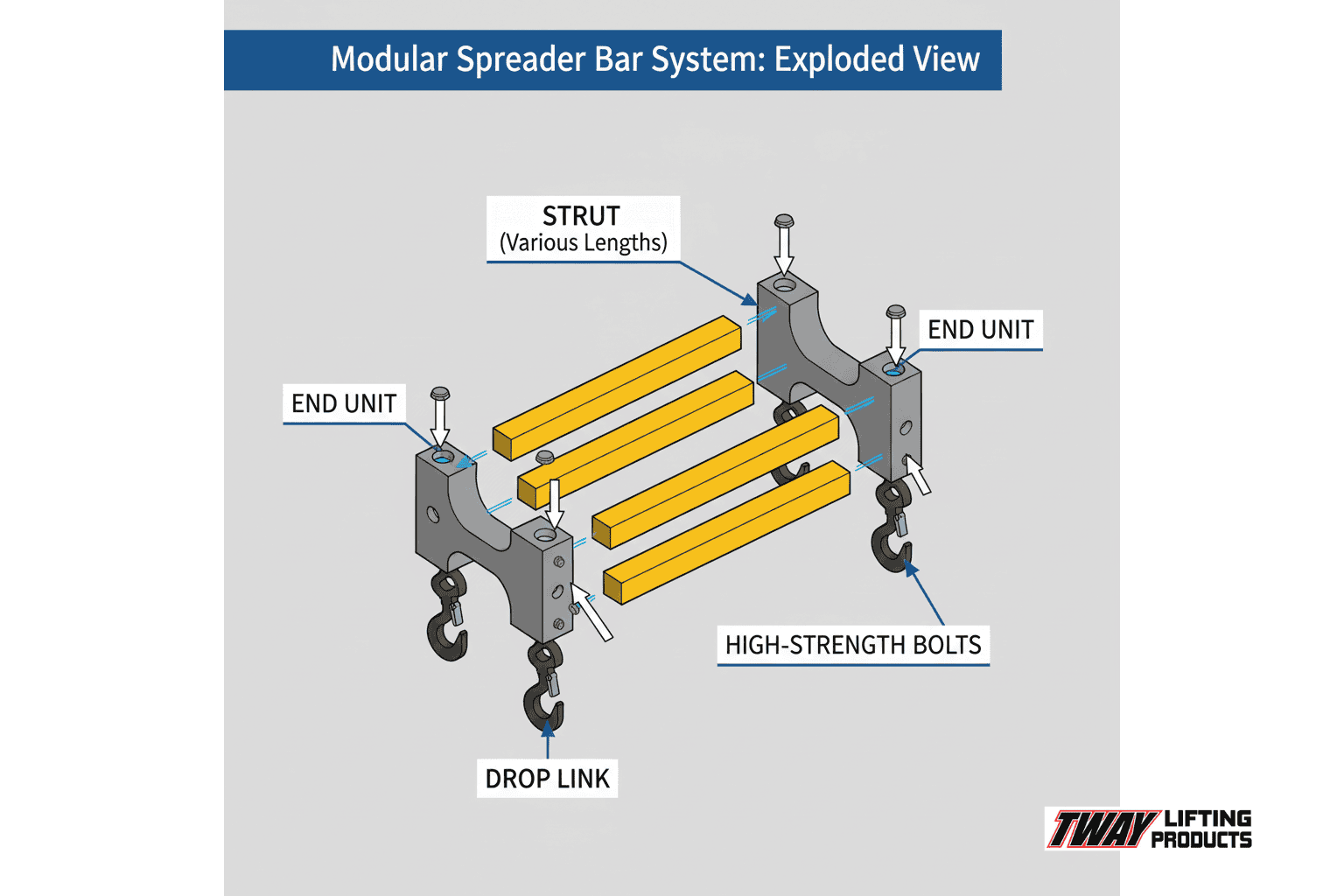

A modular spreader bar system consists of four primary components that bolt together to form a complete lifting solution. End units connect to the crane hook and provide upper lifting points for secure attachment. Struts are interchangeable sections of various lengths that bolt together to form the main beam structure.

Drop links allow for precise load positioning and multi-point attachment at the bottom of the system. High-grade nuts and bolts are critical for ensuring structural integrity of the assembled beam during lifting operations.

| Model | Specification | Value |

| Modulift MOD® Series | Capacity Range | 2 to 3000 tonnes |

| Modulift MOD® Series | Maximum Span | 100m (330 ft) |

| Tandemloc End Caps | Load Capacity | 1,544 tonnes per end cap |

This component-based approach provides exceptional flexibility while maintaining structural integrity across diverse lifting scenarios.

How Does the Assembly of Modular Spreader Bars Differ From Other Lifting Equipment?

Assembly involves bolting components together and tightening fasteners to manufacturer’s specified torque values. The number and grade of bolts are critical for safety and must follow manufacturer’s assembly instructions precisely to ensure proper load distribution.

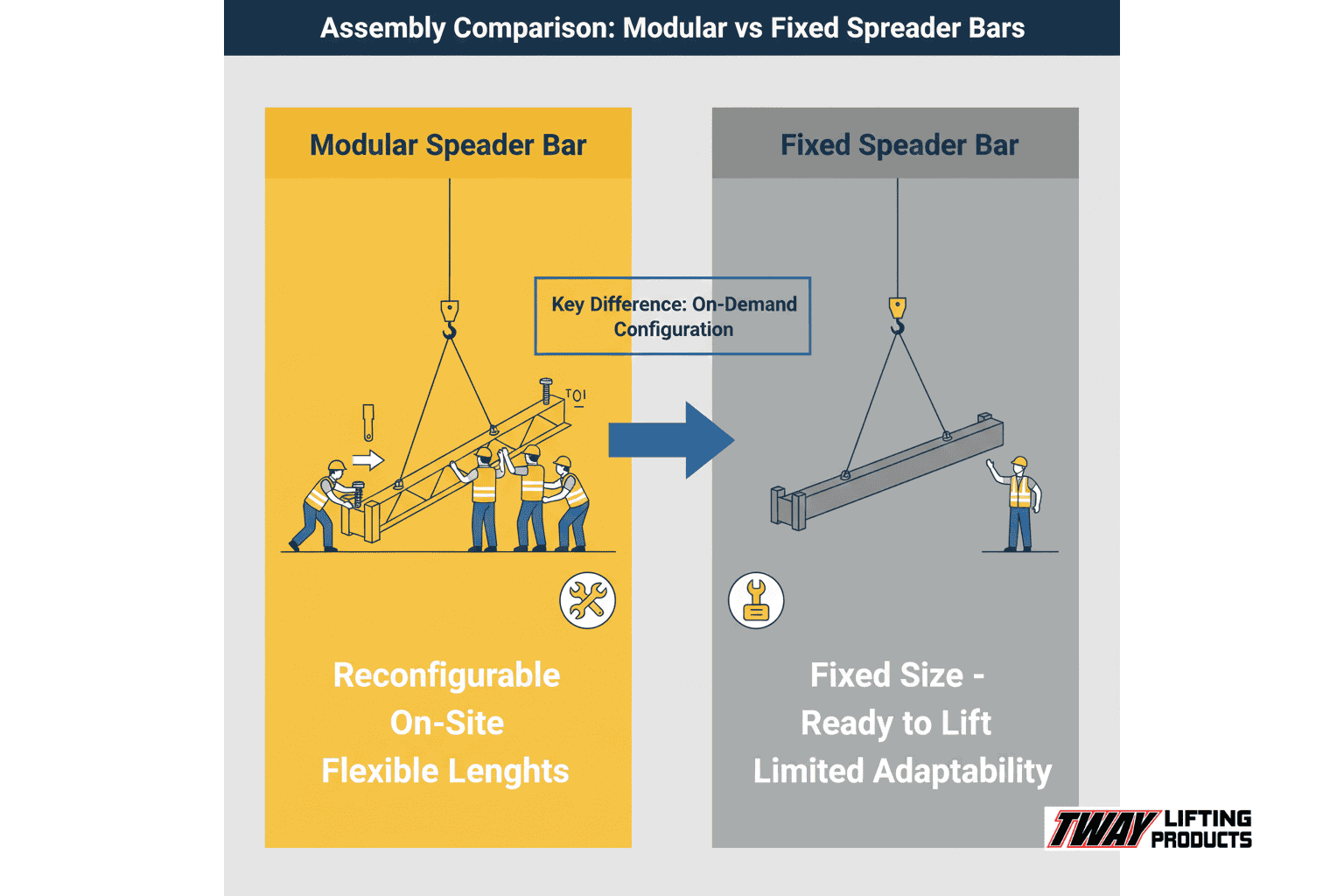

Modular design allows for quick configuration changes on-site, reducing downtime and increasing operational efficiency compared to transporting multiple fixed-size beams. Unlike fixed spreader bars that require no assembly, modular systems offer greater adaptability despite requiring setup time.

Components can be easily disassembled for compact storage and transport, eliminating the need for oversized vehicle permits and reducing shipping costs significantly.

What Are the Typical Load Capacities and Design Features?

Load capacity is determined by the combination of end units, struts, and drop links used in the configuration. Different manufacturers offer varying capacity ranges to meet specific application requirements.

Key capacity specifications include:

- LGH Modular 400/250 handles up to 250 tonnes with varying configurations

- OX-RUD Spreader Beams range from 9 to 1350 tonnes with DNV certification

- Modulift systems feature DNV Type Approval up to 600 tonnes

According to market research, the global spreader bar market was valued at USD 765 million in 2024 and is projected to reach USD 1,293 million by 2033, representing a compound annual growth rate of 5.8%.

This growth reflects increasing demand for versatile lifting solutions across construction, manufacturing, and energy sectors where modular systems provide cost-effective alternatives to multiple fixed-capacity devices.

When Should You Use Modular Spreader Bars Instead of Other Lifting Solutions?

Modular spreader bars are ideal when lifting operations require frequent reconfiguration, varying load sizes, or cost-effective replacement of multiple fixed systems. These versatile lifting solutions excel in dynamic work environments where flexibility and adaptability outweigh the convenience of fixed equipment.

The following sections examine specific scenarios, industry applications, and comparative advantages to help determine when modular spreader bars represent the optimal lifting solution for your operations.

What Types of Lifting Scenarios Are Ideal for Modular Spreader Bars?

Modular spreader bars excel in precision four-point lifting systems, such as those used at NASA’s Flight Dynamics Research Facility for critical aerospace components. These systems provide superior load control and distribution compared to single-point lifting methods.

Projects requiring frequent span and capacity adjustments between lifts benefit significantly from modular designs. Construction sites handling varying precast concrete panels, steel beams of different lengths, and bridge segments with changing dimensions require this adaptability. Manufacturing facilities processing different product sizes throughout the day also leverage this flexibility.

Operations where one system must replace multiple fixed beams achieve substantial cost-effectiveness through modular solutions. Job sites with varying load sizes and configurations on the same project eliminate the need for multiple specialized lifting devices, reducing equipment inventory and transportation costs.

Which Industries and Projects Commonly Require Modular Spreader Bars?

The construction industry uses modular spreader bars extensively for lifting precast concrete panels, steel beams, and bridge segments where load dimensions vary throughout projects. These applications require precise positioning and load distribution across multiple attachment points.

Oil and gas operations handle large, heavy equipment on offshore platforms and refineries where space constraints and varying equipment sizes demand flexible lifting solutions. Wind energy installations require modular systems for lifting and installing wind turbine blades and nacelles, where precise positioning and load control are critical for safety and efficiency.

Shipping and logistics operations utilize modular spreader bars for loading and unloading containers and heavy cargo of varying dimensions. The manufacturing sector increasingly adopts these systems to enhance safety and operational efficiency when handling diverse product lines and equipment configurations.

How Do Modular Spreader Bars Compare to Fixed Spreader Bars or Lifting Beams?

Modular systems offer high versatility through reconfiguration for different spans and capacities, while fixed spreader bars provide lower initial costs but are designed for repetitive lifts of identical loads. Fixed systems excel in applications with consistent load requirements and minimal configuration changes.

Modular bars achieve compact storage when disassembled, contrasting with fixed bars that remain bulky and difficult to transport between job sites. This portability advantage becomes significant for companies operating across multiple locations or projects with varying equipment requirements.

One modular system can replace multiple fixed beams, reducing overall equipment costs despite higher initial investment. The operational flexibility and reduced inventory requirements typically offset the premium pricing, particularly for companies handling diverse lifting applications or operating in space-constrained environments.

This analysis reveals that modular spreader bars excel in dynamic environments requiring frequent reconfiguration, while fixed systems remain optimal for repetitive, identical lifting operations with consistent requirements.

What Are the Main Benefits and Limitations of Using Modular Spreader Bars?

Modular spreader bars provide significant operational advantages while requiring careful consideration of their limitations. These systems transform lifting operations through enhanced versatility and safety features, though they demand proper assembly procedures and compliance with safety standards.

What Advantages Do Modular Spreader Bars Offer in Terms of Versatility and Safety?

Modular spreader bars offer adaptability to various load sizes and configurations, providing enhanced flexibility and efficiency on job sites. Integration of IoT and AI enables real-time load monitoring, predictive maintenance, and remote control capabilities that improve operational oversight.

Smart features enhance safety through anti-collision systems and load-sensing capabilities that provide operational control. The use of lightweight, high-strength materials like advanced steel alloys and composites improves efficiency while reducing fuel consumption across lifting operations.

Benefits include:

- Compact storage and easy transport when disassembled

- Reduced logistics costs through modular design

- Real-time monitoring capabilities for predictive maintenance

- Enhanced load positioning accuracy through smart sensors

These advantages make modular systems particularly valuable for projects requiring frequent configuration changes and precise load control.

Are There Any Disadvantages or Limitations to Be Aware Of?

The limitations of modular spreader bars center on human factors and assembly requirements. Human error contributes to 90% of crane accidents, while rigging failures account for 60% of crane-related fatalities, according to industry safety data.

Economic impact statistics reveal significant costs: the average workplace injury from lifting operations costs $43,000, while fatalities can exceed $1.46 million in total costs. These figures underscore the importance of proper training and procedures.

Key limitations include:

- Assembly time requirements before use, unlike fixed spreader bars

- Common failure modes from overloading, fatigue, and improper use

- Higher complexity requiring specialized training

- Potential for configuration errors during assembly

Operators must understand that modular systems demand more setup time and careful attention to assembly procedures compared to fixed alternatives.

How Does the Use of Modular Spreader Bars Align With OSHA and Other Safety Standards?

The use of modular spreader bars aligns with multiple safety standards that ensure proper operation and worker protection. ASME B30.20 serves as the definitive safety standard for below-the-hook lifting devices, including spreader bars, while ASME BTH-1 provides design criteria specifying requirements for materials, welding, and fabrication.

OSHA regulations under 29 CFR 1926.251 require proof testing to 125% of rated capacity before initial use. Rigging equipment must undergo inspection prior to each shift and during use as conditions necessitate, ensuring continuous safety monitoring.

International standards include:

- EN 13155: European standard for safety requirements in design, construction, and testing

- DNV certification requirements for offshore and marine applications

- ISO 9001 quality management systems for manufacturing compliance

These standards create a comprehensive framework that protects workers while ensuring equipment reliability across diverse lifting applications.

What Factors Should You Consider When Selecting or Sizing a Modular Spreader Bar?

Selecting a modular spreader bar requires evaluating load capacity, environmental conditions, and maintenance protocols. Proper sizing prevents equipment failure and ensures safe lifting operations across diverse applications.

How Do You Determine the Correct Size and Capacity for Your Application?

Load capacity determination depends on the combined specifications of end units, struts, and drop links working together. The weakest component defines the system’s overall capacity rating.

Accurate calculation of load weight and center of gravity prevents overloading and catastrophic failure. Uneven weight distribution can create stress concentrations that exceed design limits even when total weight appears manageable.

Manufacturer capacity ranges vary significantly across brands and models. Modulift offers systems from 2 to 3,000 tonnes, while LGH handles up to 250 tonnes maximum capacity. Tandemloc’s spreader beam end caps can handle up to 1,544 tonnes per end cap.

Capacity and Span Specifications

| Model | Spec Type | Measurement | Source |

| Modulift MOD® Series | Capacity Range | 2-3,000 tonnes | Modulift 2024 |

| Modulift MOD® Series | Maximum Span | 100m (330 ft) | Modulift 2024 |

| LGH Modular 400/250 | Maximum Capacity | 250 tonnes | LGH 2024 |

| OX-RUD Spreader Beams | Capacity Range | 9-1,350 tonnes | OX-RUD 2024 |

Match span requirements to available configurations during the selection process. Some modular systems extend up to 100 meters (330 feet), enabling wide-span applications in construction and industrial settings.

What Environmental or Load Factors Might Affect Your Choice?

Growth in construction and infrastructure development drives demand for different capacity requirements across project types. According to the Global Construction Market Analysis 2024, infrastructure spending increased 12% annually, creating diverse lifting equipment needs.

Accelerating pace of global construction affects equipment availability and lead times significantly. High-demand periods may require alternative configurations or extended rental periods to secure appropriate equipment.

Material options include steel, aluminum, and composite materials for different environmental conditions:

- Steel: Maximum strength for heavy-duty applications, corrosion-resistant coatings available

- Aluminum: Lightweight option reducing crane capacity requirements, suitable for marine environments

- Composite materials: Chemical resistance for aggressive environments, reduced maintenance needs

Application-specific requirements vary between construction, shipping & marine, oil & gas, manufacturing, and logistics sectors. Each industry presents unique challenges such as corrosive atmospheres, extreme temperatures, or space constraints that influence material selection.

What Inspection and Maintenance Steps Are Necessary for Safe Operation?

Initial inspection is required before first use, performed by a qualified person with proper documentation. This inspection verifies assembly integrity, load ratings, and compliance with manufacturer specifications before operational deployment.

Frequent inspections occur daily to monthly, performed by the operator or designated person without formal documentation requirements. These inspections focus on visible damage, proper assembly, and operational readiness before each lifting operation.

Periodic inspections are required annually or as mandated by service conditions, performed by qualified personnel with comprehensive documentation. According to ASME B30.20 standards, these inspections must verify structural integrity and load-bearing capacity.

Inspection Requirements by Type

- Initial: Before first use, qualified person, documented

- Frequent: Daily/monthly, operator/designee, no documentation required

- Periodic: Annual/service-based, qualified person, documented

Thorough visual inspections identify defects such as cracks, bending, and corrosion before they lead to catastrophic failure. The Crane Safety Institute reports that 60% of crane-related fatalities result from rigging failures, making inspection protocols critical for worker safety.

Operators must receive training and qualification to understand equipment limitations and follow safe operating procedures. Proper training reduces human error, which contributes to 90% of crane accidents according to OSHA incident data.

This comprehensive approach to selection, environmental assessment, and maintenance creates a foundation for understanding proper implementation strategies with qualified equipment providers.

How Should You Approach Modular Spreader Bar Selection and Safety With a Trusted Lifting Equipment Provider?

Approaching modular spreader bar selection requires partnering with experienced providers who offer comprehensive equipment selection, safety compliance, and ongoing support services. Working with established lifting equipment specialists ensures proper sizing, certification compliance, and operational safety throughout your project lifecycle.

Can Tway Lifting Help With Modular Spreader Bar Selection, Customization, or Support?

Tway Lifting can help with comprehensive modular spreader bar selection, customization, and support services. Established in 1945, Tway Lifting operates as a leading provider of lifting and rigging equipment with extensive experience in modular spreader bar applications.

Service Capabilities:

- Fixed, adjustable, and modular spreader bars with capacities from 5 to 100 tons

- Configurable spans from 4 to 40 feet for various applications

- Rental services with nationwide delivery and pickup

- All equipment certified to meet ASME B30.20 and OSHA standards

- Technical consultation for proper equipment selection and sizing

Tway Lifting’s rental model reduces capital investment while providing access to certified equipment with proper documentation and support services.

What Are the Key Takeaways About Modular Spreader Bars and Their Proper Use?

The key takeaways about modular spreader bars center on safety compliance, proper selection, and ongoing maintenance requirements. Understanding and adhering to standards is a legal requirement that protects workers, prevents equipment damage, and ensures operational efficiency, according to the ASME Safety Standards Committee in 2023.

Critical Success Factors:

- Proper training, regular inspections, and accurate load calculations prevent equipment failures

- Many manufacturers adhere to ISO 9001 international standard for quality management systems

- Market segmentation includes adjustable, fixed, telescopic, and modular product types

- Technological advancements in materials and smart features drive market growth

- Compliance with ASME B30.20, OSHA 29 CFR 1926.251, and relevant safety standards

Selecting the right equipment provider ensures access to certified equipment, proper documentation, technical support, and compliance with all applicable safety standards for successful lifting operations.