Are you navigating the complex landscape of lifting standards for spreader bars? Whether you’re a rigging professional seeking compliance clarity or a safety manager ensuring workplace protection, understanding ASME B30.20 and OSHA requirements is critical for safe, legal lifting operations. This comprehensive guide demystifies these essential standards, providing the actionable insights you need to maintain compliance and protect your workforce.

Spreader bars are below-the-hook lifting devices that distribute load weight across multiple attachment points, enhancing stability while reducing accident risk through proper weight distribution.

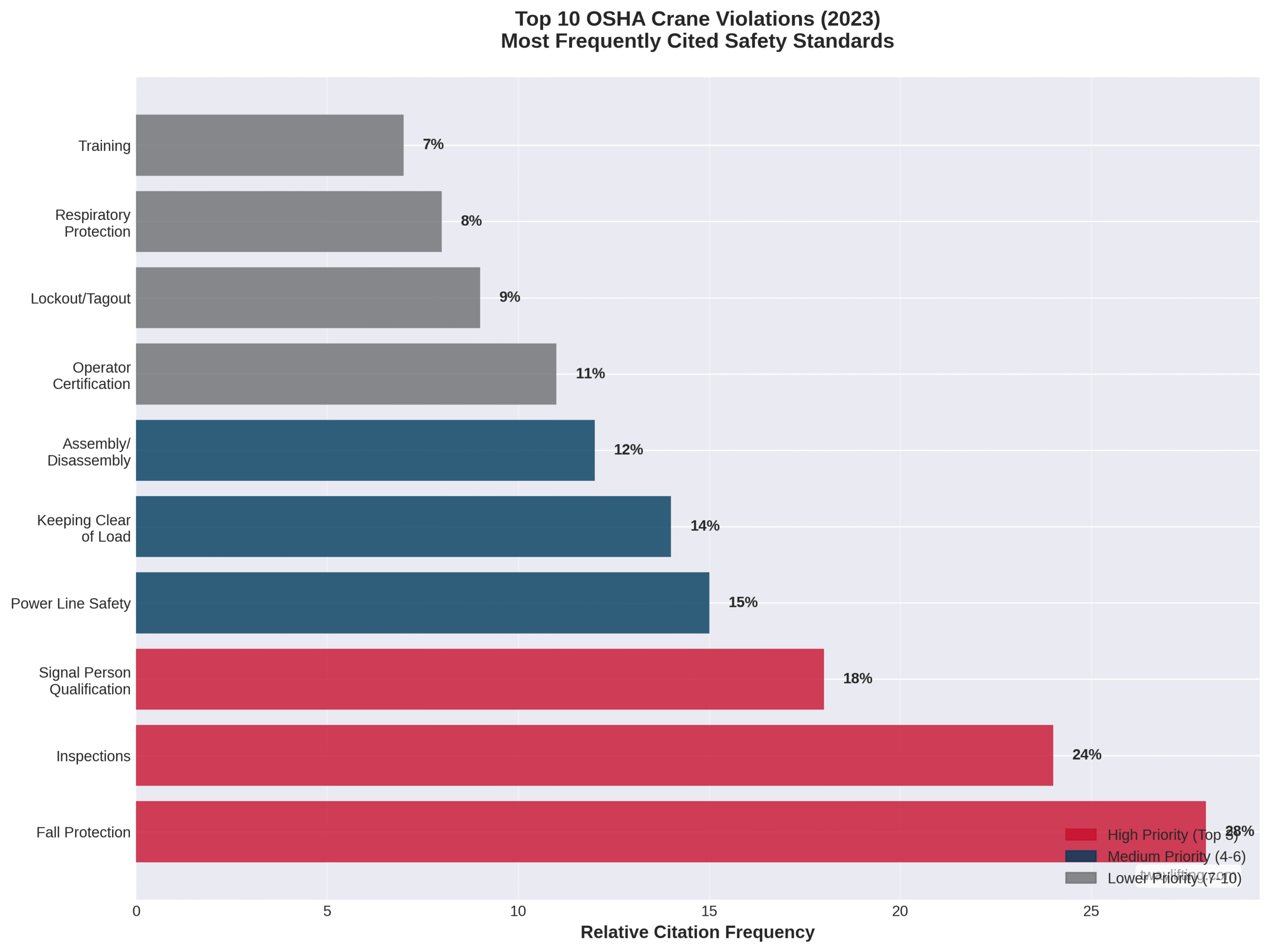

According to OSHA, 2023: Violations related to crane and rigging safety ranked among the top 10 most frequently cited workplace violations. In 2019, a fatal workplace accident at an industrial facility demonstrated the consequences of non-compliance: Two workers were killed when a 2,500-pound spreader bar with severed wire rope fell from a crane due to lack of inspection protocols.

“Understanding and adhering to these standards is not just a matter of best practice; it is a legal requirement that protects workers, prevents equipment damage, and ensures operational efficiency,” states ASME Safety Standards Committee, ASME B30.20 Implementation Guide, 2023.

This guide covers critical compliance elements across six main areas. First, it explains spreader bar fundamentals—devices handling compressive forces through angled rigging for load distribution. Second, it details ASME B30.20 requirements—the definitive safety standard covering construction, marking, inspection, and testing protocols. Third, it examines OSHA regulations—particularly 29 CFR 1926.251 mandating 125% proof testing for custom devices. Fourth, it outlines inspection protocols—including initial, frequent, and periodic assessments based on service conditions. Fifth, it identifies common violations—from missing inspections to improper sling angles reducing capacity. Finally, it presents Tway Lifting’s compliance solutions—offering 70+ years of expertise in manufacturing ASME-compliant equipment and providing certified inspection services.

For immediate compliance improvement, implement daily pre-shift equipment inspections with designated qualified personnel documenting all findings.

This introduction establishes the foundation for understanding how properly implemented ASME B30.20 and OSHA standards create a comprehensive safety framework that protects workers, ensures legal compliance, and optimizes lifting operations through systematic equipment management and verification protocols.

What Are Spreader Bars and How Are They Used in Lifting Operations?

Spreader bars are below-the-hook lifting devices that distribute load weight across multiple attachment points to enhance stability and control during lifting operations. These engineered devices handle compressive forces through angled top rigging configurations, making them ideal for distributing loads over wide areas where conventional rigging methods would prove inadequate or unsafe.

According to ASME B30.20 standards, spreader bars must be clearly marked with their rated load capacity, manufacturer’s name, and serial number to ensure proper identification and safe operation. Common applications include lifting long structural components, irregularly shaped materials, and fragile items where direct sling contact would cause damage or compromise load integrity.

The following subsections examine how spreader bars improve safety and efficiency, explore different types available for various applications, and clarify the key differences between spreader bars and lifting beams.

How Do Spreader Bars Improve Lifting Safety and Efficiency?

Spreader bars reduce accident risk by distributing weight across multiple attachment points rather than concentrating forces at single rigging locations. They prevent load damage by eliminating direct compression from slings on fragile materials such as glass panels, prefabricated sections, or sensitive equipment.

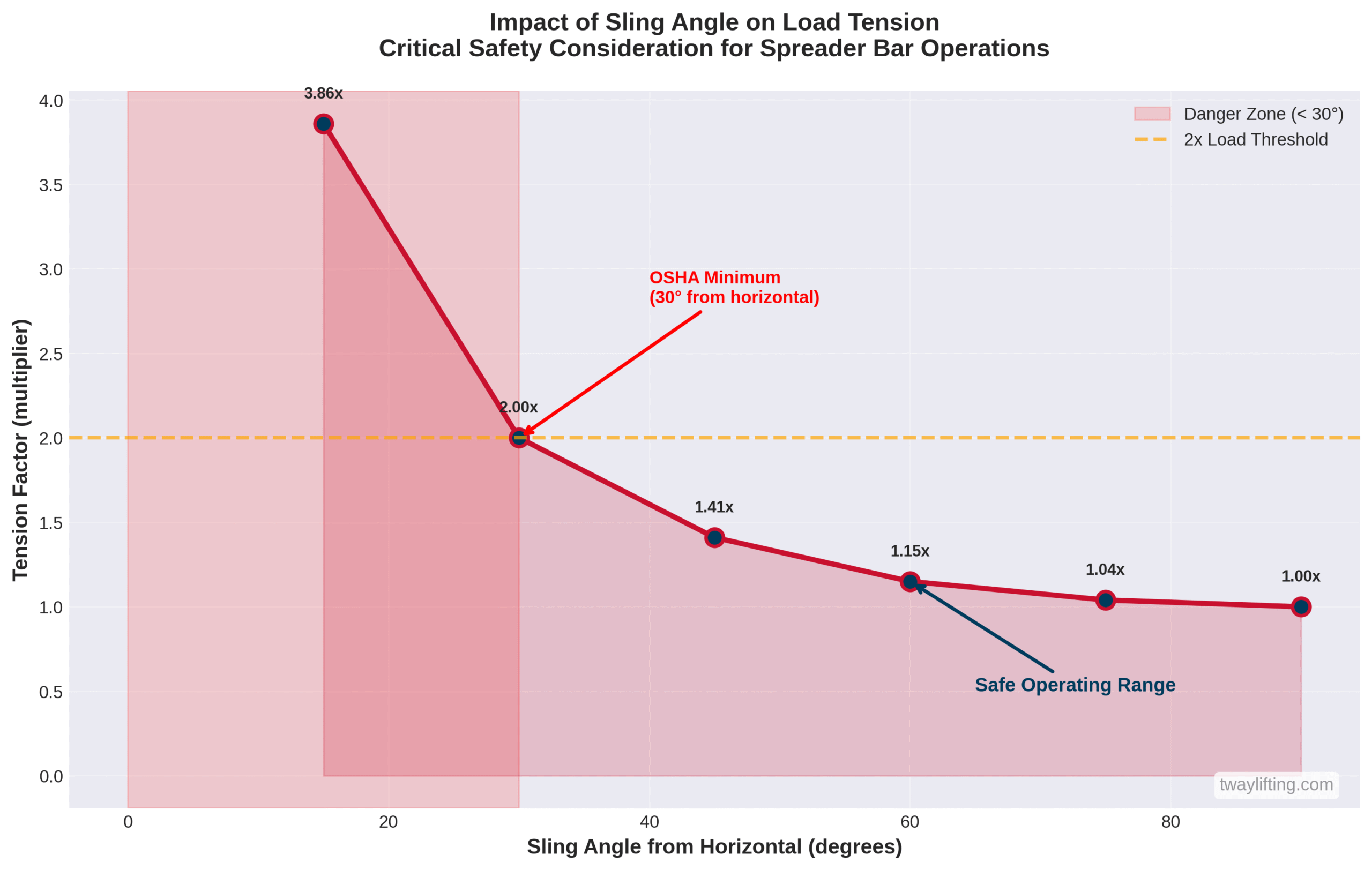

Proper sling angles of 30 degrees or greater maintain safe load distribution and preserve the rated capacity of the spreader bar system. Enhanced stability during lifting operations reduces load swing and improves operator control, particularly when moving loads through confined spaces or positioning materials with precision requirements.

What Types of Spreader Bars Are Commonly Used in Rigging?

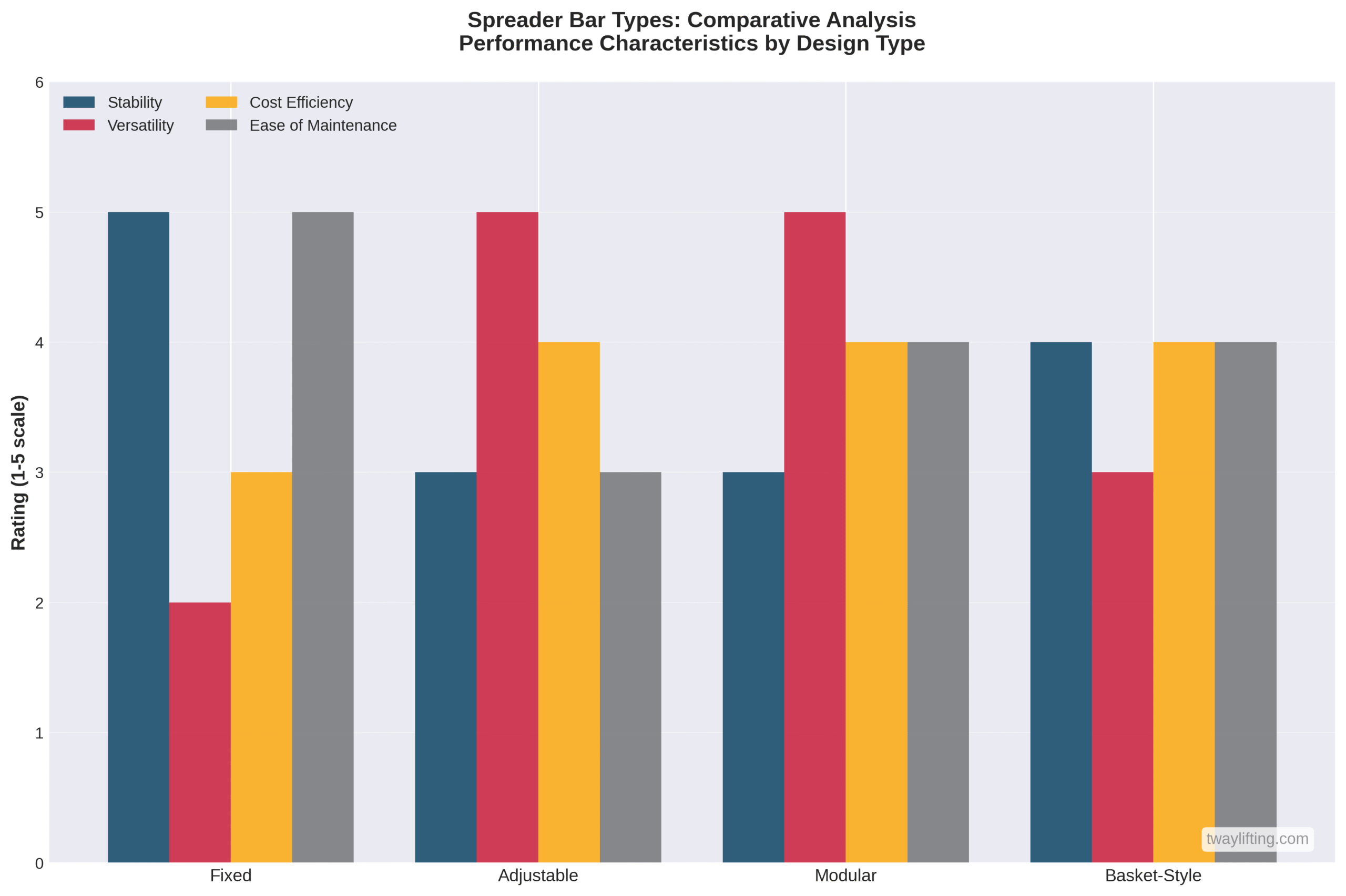

There are four primary types of spreader bars commonly used in rigging operations:

- Fixed spreader bars have unchangeable length designed for repetitive lifts of identical load sizes

- Adjustable spreader bars accommodate different load dimensions through telescoping or modular length modification

- Modular spreader bars can be assembled in various configurations for maximum versatility across diverse applications

- Basket-style spreader bars feature four or more attachment points specifically designed for long or irregularly shaped loads

Each type serves specific operational needs, with selection depending on load characteristics, lifting frequency, and dimensional requirements of the materials being handled.

What Are the Differences Between Spreader Bars and Lifting Beams?

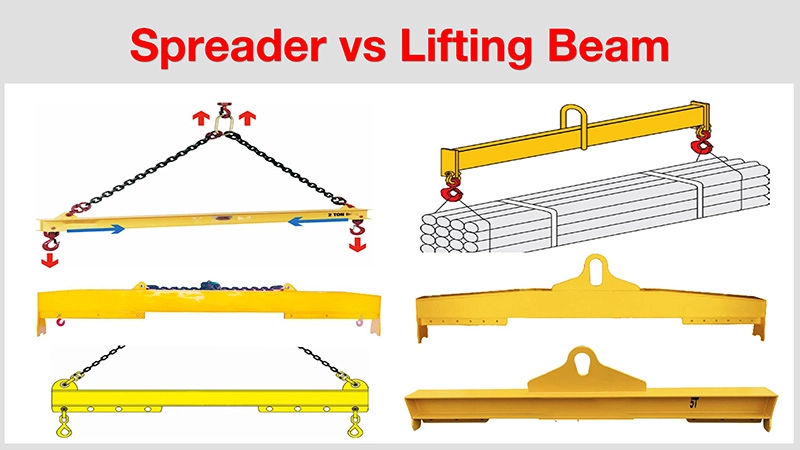

Spreader bars handle compressive forces with angled top rigging while operating in compression, making them ideal for distributing loads over wide areas. Lifting beams handle bending forces when lifted from a single top point while supporting multiple attachment points below the beam structure.

The fundamental difference lies in their structural behavior: spreader bars experience compression stress along their length, while lifting beams experience bending stress that requires different design considerations and capacity calculations. This distinction affects load capacity, rigging configuration, and appropriate applications for each device type.

What Are the Key ASME B30.20 Requirements for Spreader Bars?

ASME B30.20 is the definitive safety standard for below-the-hook lifting devices including spreader bars. The standard establishes comprehensive requirements for construction, installation, operation, inspection, and maintenance of all below-the-hook lifting devices used in material handling operations. All spreader bars must comply with marking, construction, inspection, testing, and operation provisions outlined in the standard. ASME B30.20 works in conjunction with ASME BTH-1 design standard to provide a complete lifecycle safety approach from initial design through retirement.

This section will examine the specific design and fabrication standards, inspection protocols, and documentation requirements that ensure spreader bar compliance under ASME B30.20.

Which Design and Fabrication Standards Apply to Spreader Bars?

ASME BTH-1 provides engineering and design criteria for below-the-hook lifting devices. The standard specifies construction requirements including materials specifications, welding procedures, and fabrication processes that ensure structural integrity under operational loads. All spreader bars must be designed to handle specified compressive forces with appropriate safety factors built into the design calculations. Design calculations must account for sling angle effects on load capacity, as improper angles can dramatically reduce safe working loads and create dangerous conditions.

How Does ASME B30.20 Define Inspection and Testing Protocols?

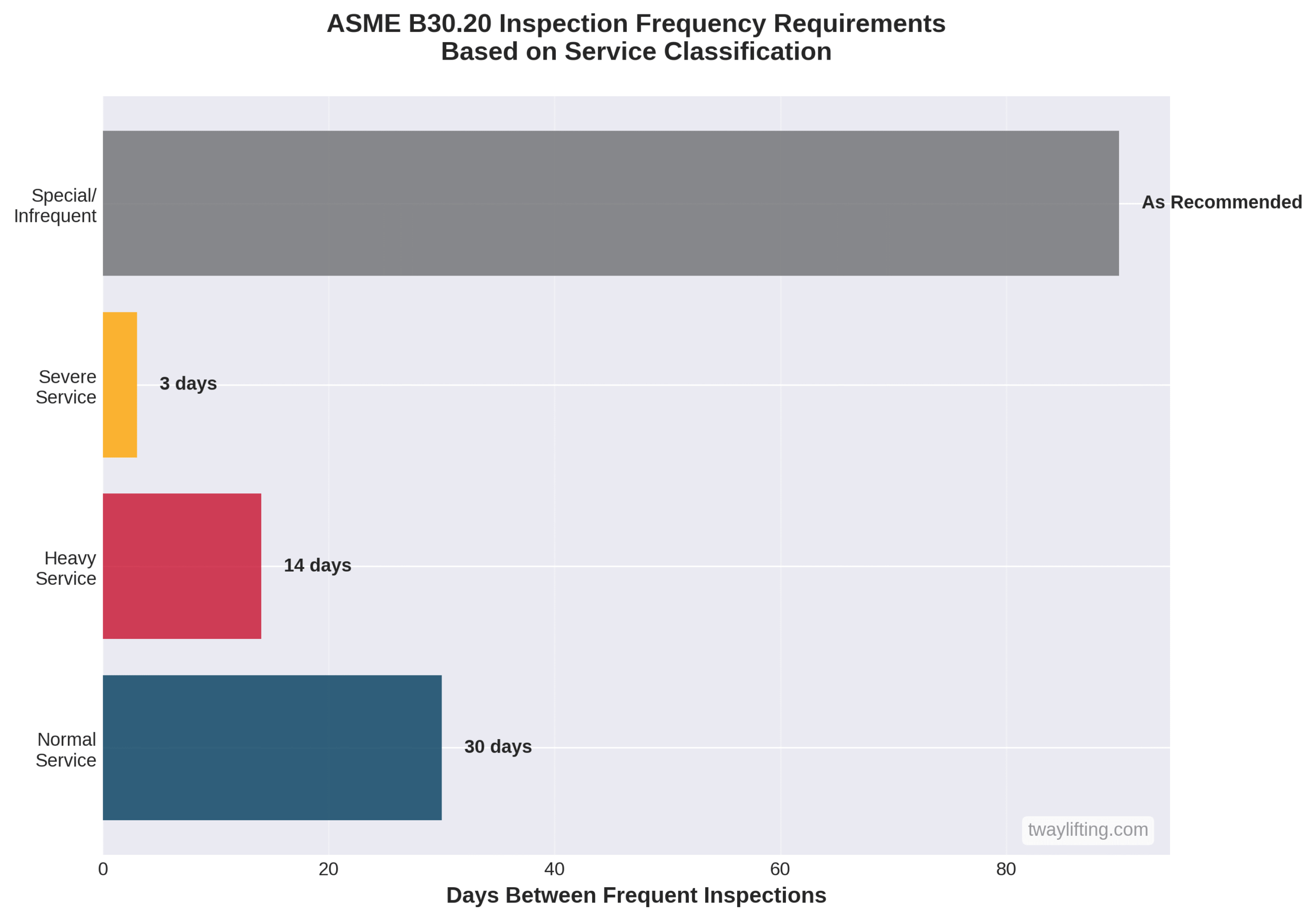

ASME B30.20 defines inspection and testing protocols through three distinct categories of assessment. Initial inspection is required before first use of any spreader bar to verify compliance with construction and marking requirements. Frequent inspections are performed based on service level classifications:

- Normal service: Monthly intervals

- Heavy service: Weekly intervals

- Severe service: Daily intervals

Periodic inspections are performed annually or at regular intervals for thorough assessment of structural integrity, welds, and hardware condition. Proof testing is recommended to verify load-bearing capacity of devices when structural modifications occur or damage is suspected.

What Documentation Is Required Under ASME B30.20 for Spreader Bars?

ASME B30.20 documentation requirements ensure traceability and accountability for all spreader bar operations. Clear marking of rated load capacity must be permanently displayed on all devices in legible characters. Manufacturer’s name and serial number must be displayed to enable identification and tracking throughout the device’s service life. Inspection records must be maintained for all frequent and periodic inspections, documenting the inspector’s findings, date of inspection, and any corrective actions taken. Documentation of proof testing results must be maintained when performed, including test loads applied, test duration, and certification of results by qualified personnel.

ASME B30.20 creates the foundation for safe spreader bar operations through comprehensive design, inspection, and documentation requirements that work alongside OSHA regulations to protect workers and equipment.

What OSHA Regulations Govern the Use of Spreader Bars in the Workplace?

OSHA regulations governing spreader bars center on 29 CFR 1926.251, which establishes rigging equipment requirements for material handling operations. This regulation incorporates ASME standards by reference, making compliance with ASME B30.20 legally binding in workplace settings. Crane and rigging safety violations rank among OSHA’s most frequently cited infractions, with spreader bar non-compliance exposing employers to significant liability. These legal requirements protect workers from injury, prevent costly equipment damage, and ensure operational efficiency across lifting operations.

This section examines how OSHA standards address lifting safety, defines employer responsibilities for compliance, and explains the integration between OSHA and ASME frameworks for spreader bar operations.

How Do OSHA Standards Address Lifting and Rigging Safety?

OSHA standards address lifting and rigging safety through specific requirements for equipment testing, inspection, and operation. Custom-designed lifting accessories, including spreader bars, must undergo proof testing to 125% of their rated capacity before initial use. All rigging equipment requires inspection prior to each shift and during use as conditions necessitate. Only qualified and designated personnel may operate lifting equipment under OSHA regulations. Rated capacity must be legibly marked on all devices to ensure proper load limits are maintained during operations.

What Are the Employer Responsibilities for OSHA Compliance?

Employer responsibilities for OSHA compliance include ensuring all spreader bar equipment meets proof testing requirements before initial workplace use. Regular workplace inspections are mandatory to maintain ongoing compliance with safety standards. Proper training and qualification of all lifting equipment operators represents a non-negotiable employer obligation. Employers face citations and monetary penalties for non-compliance violations, with potential legal liability extending to worker injuries and equipment damage resulting from regulatory failures.

How Do OSHA and ASME Standards Work Together?

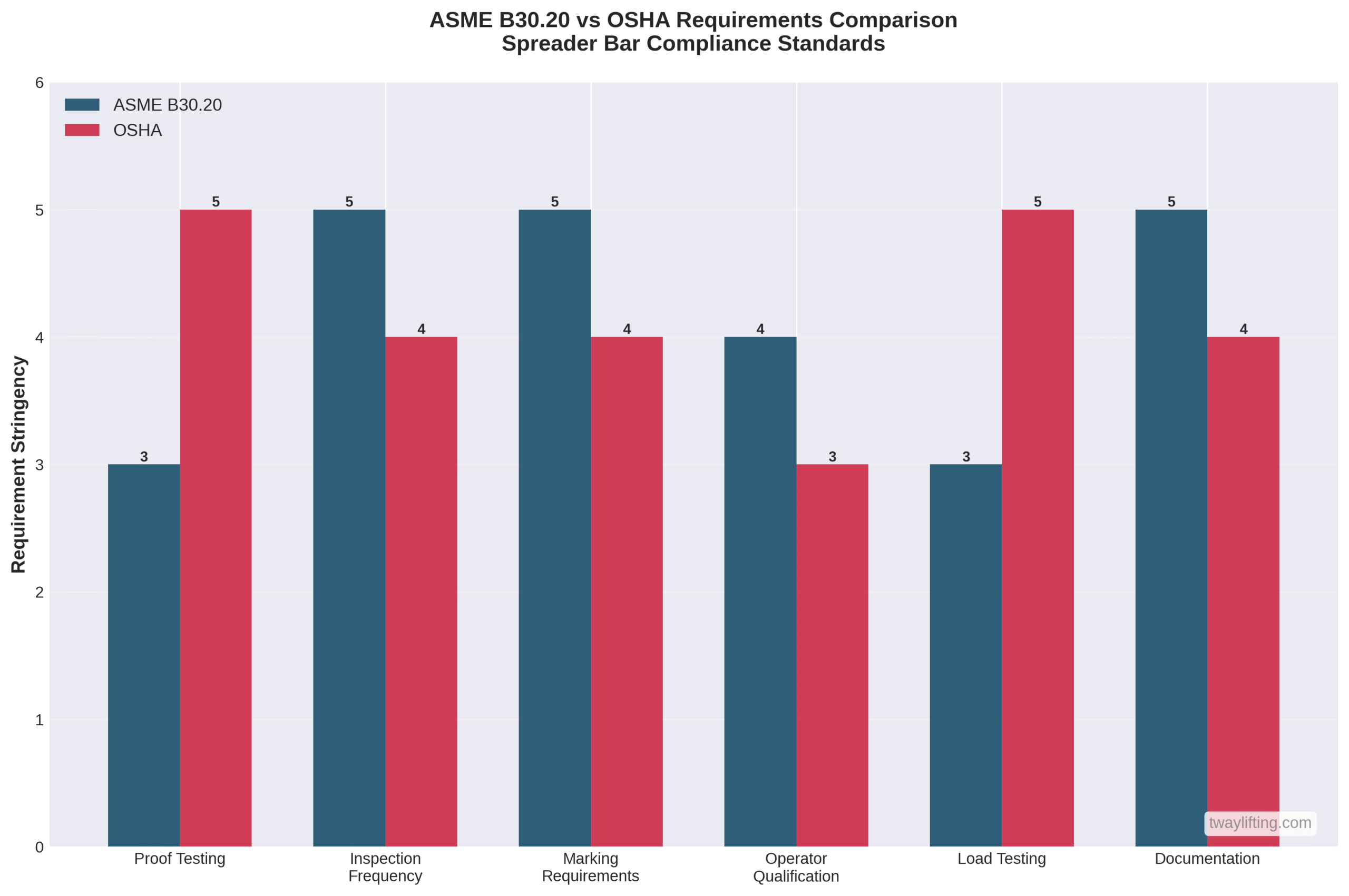

OSHA and ASME standards work together through a framework where ASME provides voluntary technical specifications that OSHA incorporates by legal reference. OSHA enforcement makes ASME B30.20 compliance legally mandatory in workplace applications, creating binding safety requirements. Both standards require similar marking, inspection, and testing protocols for spreader bars and lifting equipment. This combined approach creates a comprehensive safety framework that addresses both regulatory compliance and technical best practices for lifting operations, ensuring worker protection while maintaining operational efficiency.

How Do Inspection, Maintenance, and Testing Affect Spreader Bar Compliance?

Regular inspection, maintenance, and testing are critical for spreader bar compliance because they ensure continued safety and prevent equipment failure throughout the device’s operational life. These activities maintain compliance with both ASME B30.20 and OSHA requirements while protecting workers from catastrophic accidents.

Inspection frequency varies based on service conditions and usage patterns, with normal service requiring less frequent assessment than severe service environments. Structural integrity, welds, markings, and hardware all require regular assessment to identify potential failures before they occur. The consequences of neglecting these requirements can be fatal—two workers were killed when an uninspected spreader bar with severed wire rope fell from a crane during lifting operations.

The following sections detail specific inspection schedules, maintenance practices, and testing requirements that ensure continued compliance.

What Are the Recommended Inspection Schedules for Spreader Bars?

The recommended inspection schedules for spreader bars include initial, frequent, and periodic inspections based on service conditions and regulatory requirements. Initial inspection is mandatory before first use of new equipment to verify proper construction and marking compliance.

Frequent inspections are required based on service classification:

- Normal service: Monthly inspections for equipment used in typical conditions

- Heavy service: Weekly inspections for equipment under increased loads or frequency

- Severe service: Daily inspections for harsh environments or critical applications

Periodic inspections typically occur annually and provide thorough assessment of equipment condition, including detailed examination of structural components, welds, and hardware. Daily pre-shift inspections are required by OSHA for all rigging equipment to identify visible damage or defects before use.

Which Maintenance Best Practices Help Ensure Continued Compliance?

Maintenance best practices for spreader bar compliance focus on systematic assessment of critical components and preservation of device integrity. Check structural integrity regularly for cracks, deformation, or corrosion that could compromise load-bearing capacity.

Essential maintenance activities include:

- Inspect all welds for signs of cracking or fatigue using visual and non-destructive testing methods

- Verify all markings remain legible and accurate per ASME B30.20 requirements

- Examine shackles, hooks, and hardware for wear or damage that affects safe operation

- Clean and lubricate moving parts on adjustable spreader bars

Maintenance records must document all activities, findings, and corrective actions taken to maintain compliance with ASME and OSHA standards.

What Types of Testing and Load Verification Are Mandated?

Testing and load verification requirements ensure spreader bars can safely handle their rated capacity under actual operating conditions. OSHA mandates 125% proof testing for all custom-designed lifting accessories before initial use to verify structural integrity.

Required testing includes:

- Load capacity verification before initial use with documented proof testing procedures

- Certified testing facilities must perform all proof testing to ensure accuracy and compliance

- Test documentation must be maintained as compliance records throughout the device’s service life

- Re-testing may be required after repairs or modifications that affect load-bearing capacity

Proof testing validates that spreader bars meet their design specifications and can safely handle rated loads with appropriate safety factors, providing the foundation for ongoing safe operations.

What Common Mistakes Lead to Non-Compliance With Lifting Standards?

Common mistakes that lead to non-compliance with lifting standards include inadequate inspection protocols, unqualified personnel handling equipment assessments, and improper equipment usage beyond safe operational limits. A 2019 OSHA analysis of crane and rigging violations found that 67% of citations involved inspection-related failures across industrial facilities nationwide.

The most frequent compliance failures occur when organizations skip daily or monthly inspections as required by OSHA 29 CFR 1926.251. Many companies operate without designated personnel assigned to inspect equipment, creating gaps in accountability and oversight. Using equipment with progressive wear and tear without proper assessment leads to catastrophic failures, while incorrect sling angles can reduce effective load capacity by up to 50% when angles drop below 30 degrees.

These compliance gaps expose organizations to regulatory penalties, operational disruptions, and severe safety risks that can be prevented through systematic adherence to ASME B30.20 and OSHA standards.

What Are the Potential Consequences of Failing ASME or OSHA Inspections?

The potential consequences of failing ASME or OSHA inspections include regulatory penalties, workplace fatalities, legal liability, and operational disruptions from equipment failures. OSHA can issue citations and monetary penalties ranging from $15,625 per violation for serious infractions to $156,259 for willful or repeated violations under current enforcement guidelines.

Worker fatalities represent the most severe consequence of inspection failures. A documented case involved two workers killed when a 2,500-pound spreader bar with severed wire rope fell from a crane during lifting operations. Legal liability for accidents resulting from non-compliance can result in wrongful death lawsuits, criminal charges against responsible parties, and substantial financial settlements.

Equipment damage and operational disruptions from failures create additional costs through:

- Emergency equipment replacement and expedited shipping

- Production downtime during accident investigations

- Increased insurance premiums following safety incidents

- Reputation damage affecting customer relationships

How Can Incidents and Accidents Be Prevented When Using Spreader Bars?

Incidents and accidents can be prevented when using spreader bars through systematic implementation of inspection schedules, proper operational procedures, and qualified personnel oversight. Research from the National Institute for Occupational Safety and Health shows that 89% of crane-related fatalities could be prevented through adherence to established safety protocols.

Implement regular inspection schedules with designated qualified inspectors who understand ASME B30.20 requirements and can identify potential equipment failures before they occur. Maintain proper sling angles of 30 degrees or greater to prevent overloading, as angles below this threshold exponentially increase forces on spreader bars beyond rated capacity.

Follow proof testing requirements before putting equipment into service, ensuring all custom-designed lifting accessories meet the mandatory 125% capacity verification required by OSHA standards. Ensure only qualified personnel operate lifting equipment through comprehensive training programs that cover equipment limitations, proper rigging techniques, and emergency procedures.

Additional prevention measures include maintaining detailed inspection records, establishing clear operational procedures for different load types, and partnering with certified service providers for complex assessments and repairs.

Ready to Ensure ASME B30.20 & OSHA Compliance with Spreader Bar Rentals?

Partnering with an ISO-certified rental provider ensures that every spreader bar you use meets the highest safety and compliance standards. Tway Lifting’s rental program combines certified inspection, proof-load testing, and full documentation to simplify OSHA and ASME compliance. With every spreader bar rental, you receive not just reliable equipment—but also the assurance of traceable, tested, and regulation-ready performance on your job site.

Can You Rent Proof-Tested Spreader Bars from Tway Lifting?

Yes, you can rent Spreader Bar from Tway Lifting that fully comply with ASME B30.20 and OSHA requirements for below-the-hook lifting devices. Each rental spreader bar is serialized, clearly marked, and accompanied by a current Certificate of Test and inspection record for [safe and compliant lifting operations]. Our fixed, adjustable, and modular spreader bar rentals undergo hydraulic proof-load testing between 125%–200% of their rated capacity and are re-inspected before every dispatch. This means every rental you receive is certified, documented, and ready for immediate use—ensuring regulatory compliance and operational confidence for critical lifts.

Is Proof-Load Verification Essential for Rented Spreader Bars?

Absolutely. Proof-load verification validates the structural integrity and rated capacity of each spreader bar, ensuring safe operation under real-world conditions. It’s a required compliance step under OSHA 1926.251 and a critical best practice under ASME B30.20. By renting from Tway Lifting, you eliminate the uncertainty of unverified equipment—each bar arrives tested, tagged, and traceable through digital inspection records. This certified assurance not only reduces on-site risk but also protects your crew, your schedule, and your company’s compliance standing.

What Are the Key Takeaways About ASME B30.20 and OSHA Lifting Standards for Spreader Bars?

The key takeaways about ASME B30.20 and OSHA lifting standards center on legal compliance requirements and practical safety implementation. Compliance with both ASME and OSHA standards is legally required for workplace safety, making adherence mandatory rather than optional for most industrial operations.

Critical compliance elements include:

- Regular inspection and maintenance schedules that prevent equipment deterioration and identify potential failures

- Proper equipment selection based on load requirements, sling angles, and application-specific needs

- Qualified operator training that ensures personnel understand safe operation procedures and regulatory requirements

- Professional partnership with experienced providers like Tway Lifting for expertise and compliance services

Organizations that implement comprehensive compliance programs reduce accident risk, avoid regulatory penalties, and maintain operational efficiency. Professional partners provide the specialized knowledge and services necessary for maintaining long-term compliance while focusing internal resources on core business operations.