If you’re tasked with lifting heavy or irregularly shaped loads, you understand the critical importance of selecting proper rigging equipment. Poor spreader bar selection can lead to catastrophic failures, damaged materials, and serious injuries. You need confidence that your lifting equipment matches your specific application requirements while maintaining the highest safety standards.

Choosing the right spreader bar for your lift is a systematic process that involves evaluating load weight, dimensions, center of gravity, environmental conditions, and applicable safety standards. According to the U.S. Bureau of Labor Statistics, 2023: 297 crane-related fatalities occurred from 2011-2017, with rigging failures contributing to as many as 60% of crane-related deaths. “Spreader bars are essential below-the-hook lifting devices used in a wide range of industries to safely and efficiently lift heavy, bulky, or irregularly shaped loads,” states Peter Hansen, CEO of Tway Lifting Products, 2024.

Start by assessing your load’s weight against the spreader bar’s Working Load Limit—never exceed the rated capacity. Consider whether you need a spreader beam (handles compressive stress, requires headroom) or lifting beam (handles bending stress, ideal for low clearance). Evaluate environmental factors including temperature ranges and corrosive exposure. Match your rigging hardware compatibility. Choose between fixed bars for repetitive lifts or adjustable/telescopic options for varying loads. Verify compliance with OSHA 1926.251 and ASME B30.20 standards. Perform mandatory daily inspections before each shift.

Always prioritize capacity ratings and environmental conditions when selecting spreader bars—proper equipment prevents accidents and ensures operational efficiency.

This introduction establishes the foundation for understanding how proper spreader bar selection directly impacts lifting safety and efficiency across industrial applications.

What Factors Determine Which Spreader Bar Is Best for My Lifting Application?

Several critical factors determine the optimal spreader bar for your lifting application, including load characteristics, environmental conditions, and rigging compatibility. These factors work together to ensure safe, efficient lifting operations while maintaining compliance with industry standards.

How Does Load Weight and Distribution Affect Spreader Bar Selection?

Load weight and distribution directly determine the type and capacity of spreader bar required for safe lifting operations. Spreader bars must have a Working Load Limit (WLL) that exceeds the total weight of the load being lifted, with available capacities ranging from 2,000 lbs to over 100,000 lbs across different manufacturers.

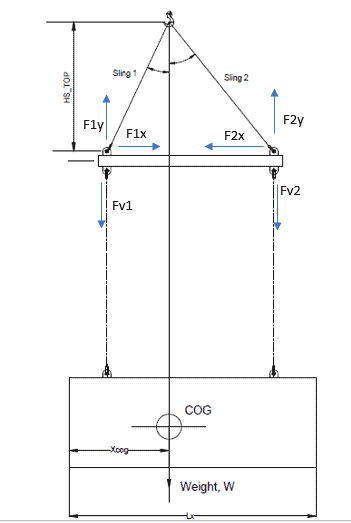

Load distribution patterns affect whether you need a spreader beam or lifting beam configuration. Spreader beams handle compressive stress and work best for wide, heavy loads, while lifting beams handle bending stress and suit lighter applications. Center of gravity assessment proves critical for determining proper attachment points and bar configuration to prevent load tilting or instability during the lift.

ASME BTH-1 establishes specific safety factors based on design categories:

| Design Category | Yield Safety Factor | Ultimate Safety Factor |

| Category A | 2:1 | 2.4:1 |

| Category B | 3:1 | 3.6:1 |

| Category C | 6:1 | 7.2:1 |

The load’s weight distribution and lifting point locations determine which category applies to your application. This section establishes the foundation for understanding environmental and compatibility factors that complete the selection process.

What Role Does the Lift Environment Play in Choosing a Spreader Bar?

The lift environment plays a decisive role in spreader bar selection through headroom constraints, temperature conditions, and exposure hazards. Indoor applications with limited headroom typically require lifting beams rather than spreader beams, since spreader beams need additional vertical space to accommodate top rigging connections.

Operating temperature ranges typically span -20°C to +100°C for standard equipment, but extreme conditions require special considerations. Fiber core wire rope slings cannot be used above 200°F (93.33°C), necessitating alternative rigging solutions for high-temperature applications. Exposure to moisture and corrosive environments demands special material selections and protective coatings to prevent equipment degradation.

Environmental hazards significantly impact safety outcomes. The construction industry accounts for 43% of fatal crane-related injuries, emphasizing the importance of environmental hazard awareness during equipment selection. Factors such as wind exposure, ground conditions, and proximity to power lines must be evaluated when choosing spreader bar configurations.

Weather exposure, chemical environments, and operational frequency all influence material specifications and maintenance requirements. These environmental considerations directly connect to the final critical factor: rigging hardware compatibility.

Why Is Rigging Hardware Compatibility Important?

Rigging hardware compatibility ensures seamless integration between spreader bars, crane hooks, and lifting slings for safe lifting operations. Spreader bars must match existing crane hook configurations and sling capacities to prevent equipment mismatches that could compromise lift safety.

Special custom lifting accessories require proof-testing to 125% of their rated load per OSHA 1926.251, while welded end attachments must be proof-tested to 200% of their rated capacity. This testing ensures that all rigging components can handle the intended loads with appropriate safety margins.

Equipment must display permanently affixed, legible identification markings indicating safe working load and inspection dates. These markings allow operators to verify compatibility and current certification status before each lift operation.

Tway Lifting offers crane- and forklift-ready spreader bars designed for universal crane hooks and forklift tine pockets, providing versatile solutions that work across different equipment types. This compatibility reduces the need for multiple specialized attachments and simplifies equipment inventory management.

Proper hardware compatibility prevents rigging failures that contribute to 60% of crane-related fatalities according to industry studies. The next section explores the different types of spreader bars available to meet these compatibility and application requirements.

What Are the Different Types of Spreader Bars and How Do They Work?

The different types of spreader bars include fixed, adjustable, telescopic, and specialty configurations, each designed to handle specific lifting challenges through distinct mechanical approaches. Understanding these variations helps operators select the most efficient and safe solution for their lifting applications.

How Do Fixed and Adjustable Spreader Bars Compare?

Fixed spreader bars maintain a set length that makes them ideal for repetitive lifting of standardized loads. These bars offer reliability and cost-effectiveness for operations with consistent lifting requirements.

Adjustable spreader bars allow length modification to accommodate various load sizes and shapes. Standard models provide configurable spans from 4 to 40 feet, offering versatility for diverse lifting operations. Fixed bars cost less initially but provide limited flexibility compared to adjustable options.

The choice between fixed and adjustable depends on operational variety. Fixed bars excel in manufacturing environments with standard products, while adjustable bars suit construction sites handling varying materials. Tway Lifting offers both configurations with capacities from 5 to 100 tons.

What Are Telescopic Spreader Bars and When Should You Use Them?

Telescopic spreader bars feature a telescoping mechanism that provides greater flexibility in length adjustment compared to standard adjustable bars. These systems allow on-site customization without requiring multiple fixed-length beams.

The telescopic design reduces transportation costs and storage requirements by consolidating multiple beam lengths into one unit. Most models can be adjusted quickly between lifts without requiring tools, improving operational efficiency.

Use telescopic spreader bars when operations regularly handle varying load sizes. They work best for contractors moving between job sites or facilities with diverse lifting requirements. The telescopic mechanism offers the ultimate flexibility for unpredictable lifting scenarios.

How Do Specialty Spreader Bars Address Unique Lifting Challenges?

Specialty spreader bars solve specific lifting problems through specialized designs and configurations. Modular spreader bars can be assembled and disassembled for easy transport and customization to job-specific requirements.

Basket-style spreader bars feature four attachment points that provide increased stability with oversized loads. Lattice spreader bars use lattice structure construction to improve load-bearing capacity while maintaining rigid lifting characteristics.

The Modulift System allows for on-site customization of both beam length and capacity through interchangeable components. Heavy-duty lifting beams rated up to 100 tons handle oversized industrial loads that exceed standard equipment capabilities.

These specialty configurations address unique challenges such as awkward load shapes, extreme weights, or complex rigging requirements that standard spreader bars cannot accommodate effectively.

How Can You Ensure Safety and Compliance When Selecting a Spreader Bar?

Safety and compliance in spreader bar selection require adherence to federal standards, proper inspection protocols, and hazard prevention strategies. OSHA regulations mandate daily equipment inspections, while ASME standards establish design criteria and safety factors that prevent equipment failures. Understanding applicable standards, inspection requirements, and common lifting hazards ensures both regulatory compliance and worker safety.

What Are the Applicable OSHA and ASME Standards for Spreader Bars?

OSHA and ASME standards provide comprehensive safety frameworks for spreader bar selection and operation. OSHA standard 1926.251 governs rigging equipment for material handling, requiring competent person inspections before each shift. ASME B30.20 covers marking, construction, installation, inspection, testing, maintenance, and operation of below-the-hook devices.

Key regulatory requirements include:

- ASME BTH-1: Provides detailed design criteria with safety factors ranging from Category A (2:1 yield strength) to Category C (6:1 yield strength)

- Equipment marking: Permanent, legible identification showing safe working load

- Proof testing: Custom accessories require 125% rated load testing; welded attachments need 200% capacity testing

- Daily inspections: Mandatory competent person evaluation before each shift

Design categories establish safety margins, with Category C offering the highest protection at 6:1 yield strength safety factor for critical applications.

How Do You Perform Proper Inspections and Maintenance?

Proper inspections and maintenance prevent equipment failures and ensure OSHA compliance. Daily inspections are required before each shift per OSHA regulations, focusing on structural integrity and load capacity verification.

Essential inspection elements include:

- Visual examination: Check for deformation, cracks, or excessive wear on all components

- Attachment points: Inspect lifting lugs and connection hardware for damage

- Load markings: Verify legibility of identification markings showing safe working load

- Annual certification: Professional inspections by certified, factory-trained qualified riggers

Tway Lifting provides OSHA-required annual inspections through certified personnel, ensuring compliance with federal standards. Proper cleaning and storage protect equipment from corrosion damage, extending service life and maintaining safety ratings.

What Common Lifting Hazards Can Be Prevented With the Right Spreader Bar?

Proper spreader bar selection prevents catastrophic failures that cause crane-related fatalities. Struck-by incidents account for over half of all fatal crane injuries, with 297 crane fatalities occurring from 2011-2017 according to OSHA data. Studies indicate 60% of crane-related fatalities may be attributed to rigging failures.

Critical hazard prevention strategies include:

- Load stability: Proper spreader bar selection prevents load instability and tipping during lifts

- Capacity matching: Correct capacity selection prevents catastrophic equipment failure

- Headroom management: Using appropriate bar type for space constraints prevents collision hazards

- Rigging failure prevention: OSHA database documents fatalities from falling steel beams during spreader bar operations

Selecting spreader bars with appropriate safety factors and conducting mandatory inspections significantly reduces accident risk. Construction industry accounts for 43% of fatal crane-related injuries, emphasizing the critical importance of proper equipment selection and compliance protocols.

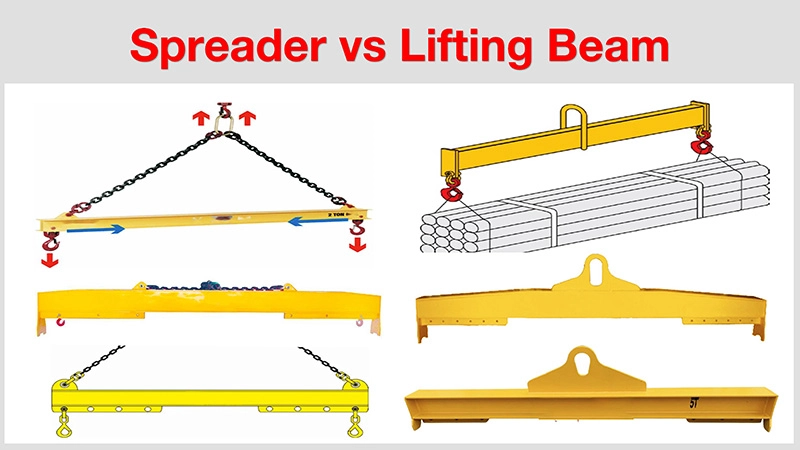

How Do Spreader Bars Compare to Lifting Beams for Lifting Applications?

Spreader bars and lifting beams serve different roles in lifting applications based on their structural design and stress distribution methods. Spreader bars handle compressive stress through tension rigging, while lifting beams manage bending stress through their rigid structure. This fundamental difference affects their weight, cost, headroom requirements, and optimal applications.

The following comparison examines the specific benefits and limitations of each system, along with guidance on when to select spreader bars versus lifting beams for your lifting operations.

What Are the Benefits and Limitations of Spreader Bars Versus Lifting Beams?

Spreader bars and lifting beams differ significantly in their structural advantages and operational constraints. Spreader beams handle compressive stress while lifting beams handle bending stress, creating distinct performance characteristics for each system.

Key advantages of spreader bars include:

- Material efficiency resulting in lighter weight designs compared to lifting beams

- Enhanced stability through wider lift points that distribute loads more evenly

- Lower cost due to reduced material requirements and simpler construction

- Superior load distribution for wide, heavy-duty applications

Primary benefits of lifting beams are:

- Single-point attachment that minimizes headroom requirements

- Increased rigidity for precise load control and positioning

- Compact design suitable for confined spaces and indoor operations

- Direct crane hook attachment without additional rigging hardware

Limitations vary by system type:

- Spreader beams require additional headroom to accommodate top rigging connections

- Lifting beams are heavier and more expensive due to increased material requirements

- Spreader beams need adequate clearance for sling angles and rigging geometry

- Lifting beams may have capacity limitations compared to equivalent spreader beam designs

When Should You Use a Spreader Bar Instead of a Lifting Beam?

Use spreader beams for wide, heavy-duty loads and outdoor applications with adequate headroom. Choose spreader beams when weight efficiency is important for the lifting equipment, as their design uses material more efficiently than lifting beams.

Select spreader beams for:

- Higher capacity lifts due to their efficient stress distribution design

- Operations where cost is a primary factor, as spreader beams are generally less expensive

- Wide loads requiring stable lift points and even load distribution

- Applications with sufficient headroom for top rigging connections

Opt for lifting beams when:

- Indoor applications have limited headroom constraints

- Single-point attachment provides operational advantages

- Lighter, shorter span lifts require precise load positioning

- Rigid load control is essential for the application

Consider the operational environment and load characteristics when making your selection. Spreader beams excel in outdoor heavy-duty applications where headroom allows for proper rigging geometry, while lifting beams perform best in confined spaces requiring compact, rigid lifting solutions.

This comparison highlights the importance of matching equipment design to application requirements, ensuring both safety and operational efficiency in your lifting operations.

What Are the Steps to Size and Specify the Right Spreader Bar?

Sizing and specifying the right spreader bar requires a systematic approach that evaluates load characteristics, safety requirements, and operational constraints. This process ensures safe, compliant lifting operations while maximizing equipment efficiency.

How Do You Calculate the Required Capacity and Length?

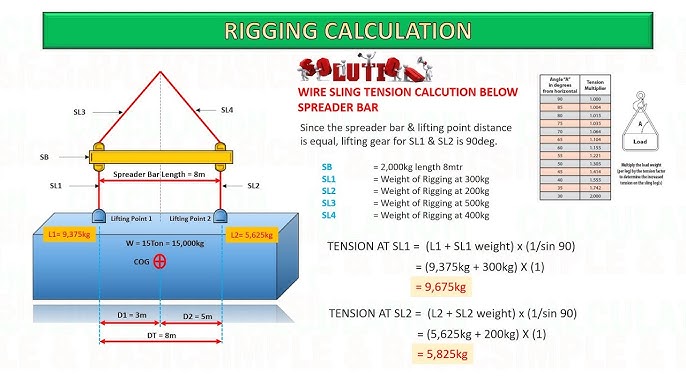

Calculating the required capacity and length involves analyzing load characteristics and applying engineering principles to determine proper specifications. Start by assessing the load’s weight, dimensions, center of gravity, and designated lifting points to establish baseline requirements.

Select a spreader bar with Working Load Limit (WLL) exceeding the total load weight by appropriate safety margins. According to ASME BTH-1 standards, safety factors vary by design category: Category A requires 2:1 yield strength, Category B requires 3:1 yield strength, and Category C requires 6:1 yield strength safety factors.

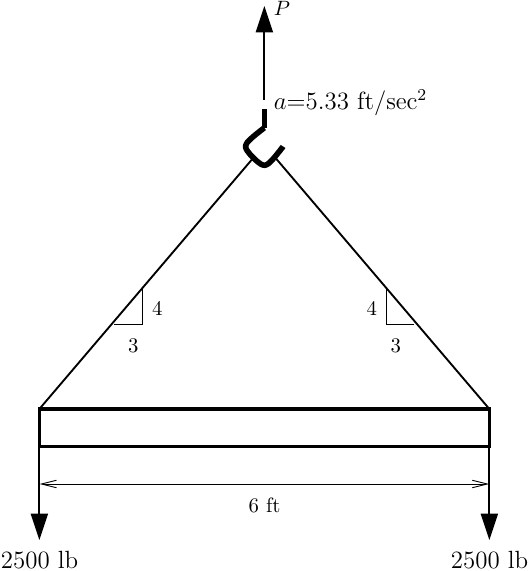

Calculate the required span based on load width and lifting point locations, ensuring adequate clearance for safe rigging. Consider sling angles carefully—angles should not exceed 60 degrees from vertical for safety compliance and load stability.

Key calculation factors include:

- Dynamic loading factors during lift operations

- Environmental conditions affecting material properties

- Appropriate safety factors per ASME BTH-1 based on design category

- Load distribution patterns and stress concentration points

Proper calculations prevent equipment failure and ensure regulatory compliance throughout the lifting operation.

What Information Should You Provide When Requesting a Quote?

Providing comprehensive information when requesting a spreader bar quote ensures accurate sizing and appropriate equipment selection. Include the total weight of the load to be lifted as the primary specification requirement.

Supply complete load dimensions including length, width, and height measurements for proper span calculations. Specify the number and exact location of lifting points on the load, as this directly affects spreader bar configuration and attachment design.

Document available headroom for the lifting operation, since this determines whether spreader beams or lifting beams are more appropriate. Environmental conditions require detailed specification, including temperature range (standard equipment operates from -20°C to +100°C) and exposure to corrosive elements that may require special protective coatings.

Essential quote information includes:

- Frequency of use and whether rental or purchase is preferred

- Any special requirements such as adjustability or modular configuration needs

- Existing crane hook specifications and rigging hardware compatibility

- Project timeline and delivery requirements

This comprehensive information enables manufacturers like Tway Lifting to recommend optimal solutions that meet both technical requirements and budget constraints while ensuring full regulatory compliance.

How Should You Approach Spreader Bar Selection With Support From Tway Lifting?

Spreader bar selection requires expert guidance to ensure safety and compliance. Tway Lifting provides comprehensive support from initial consultation through equipment maintenance, leveraging decades of industry experience to help you choose the optimal solution for your lifting requirements.

How Can Tway Lifting Help You Choose the Right Spreader Bar for Your Needs?

Tway Lifting offers professional spreader bar rental services backed by over 75 years of rigging expertise since 1945. As an ISO 9001-2008 certified manufacturer and distributor, Tway operates two Rigging Equipment Superstores in Indiana with factory-trained qualified riggers who perform equipment inspections and certifications.

Our comprehensive inventory includes spreader bars ranging from 5 to 100 tons capacity with spans from 4 to 40 feet. Tway provides both sales and rental options for:

- Fixed spreader bars for standardized loads

- Adjustable systems for varying applications

- Telescopic bars for maximum flexibility

- Modular configurations for custom requirements

As the only Peerless/Acco Welded Sling Repair Center in the region, Tway offers complete equipment reconditioning services. Our expertise extends to major projects including the Indianapolis Colts Lucas Oil Stadium and Dallas Cowboys Stadium, demonstrating capability across complex industrial applications.

What Are the Key Takeaways About How to Choose the Right Spreader Bar for Your Lift We Covered?

Proper spreader bar selection requires systematic evaluation of multiple factors to ensure safe, compliant lifting operations. Load assessment forms the foundation—you must determine weight, dimensions, center of gravity, and lifting point locations before selecting equipment.

Environmental considerations significantly impact selection:

- Headroom constraints determine spreader beam versus lifting beam choice

- Temperature ranges (-20°C to +100°C typical) affect material selection

- Corrosion exposure requires protective coatings and special materials

Regulatory compliance follows OSHA 1926.251 and ASME B30.20/BTH-1 standards governing design, testing, and inspection requirements. Daily inspections before each shift are mandatory per OSHA regulations to prevent equipment failure.

Choose spreader beams for compressive stress applications requiring headroom, or lifting beams for bending stress situations with low headroom constraints. Modular and telescopic systems provide flexibility for operations handling varying load sizes regularly.

Professional support from certified providers like Tway Lifting ensures proper selection, compliance verification, and ongoing safety through expert consultation and certified inspection services.