If you’re exploring how digital twin technology can revolutionize your lifting operations, you’ve come to the right place. Whether you’re seeking to enhance safety protocols, reduce maintenance costs, or optimize equipment design, this comprehensive guide addresses the critical questions about implementing digital twin solutions in the lifting equipment industry. We’ll show you exactly how this transformative technology delivers measurable ROI while setting new standards for operational excellence.

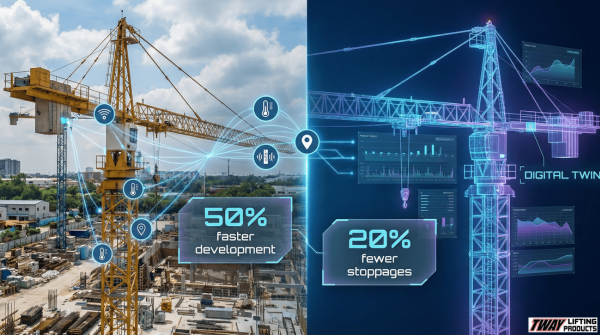

Digital twin technology in lifting equipment is a virtual representation of physical cranes, hoists, and lifting systems that serves as a real-time digital counterpart, enabling seamless integration of physical and virtual worlds for continuous monitoring, predictive maintenance, and design optimization. This revolutionary approach transforms how we design, operate, and maintain lifting equipment by creating dynamic, data-rich virtual replicas that evolve alongside their physical counterparts, delivering up to 50% reduction in development time and 20% reduction in unexpected work stoppages.

TL;DR Summary: We’ll explore what digital twins are and how they apply to lifting equipment through IoT sensors and AI algorithms. We’ll examine how this technology improves design processes by reducing prototyping costs and enabling virtual testing. We’ll detail how digital twins enhance maintenance through predictive analytics and compliance monitoring. We’ll analyze the key benefits including 20-30% operational efficiency improvements alongside implementation challenges. We’ll investigate integration with IoT devices and security considerations. We’ll forecast future trends including AI advancement and market growth projections reaching $149.81 billion by 2030. Finally, we’ll demonstrate how Tway Lifting implements these solutions to deliver smart lifting systems that represent the future of the industry.

Quick Tip: Start your digital twin journey by identifying your most critical lifting equipment and installing basic IoT sensors for vibration and load monitoring – this simple step alone can reduce unexpected downtime by 20% while building the foundation for a comprehensive digital twin system.

What Is Digital Twin Technology and How Does It Apply to Lifting Equipment?

Digital twin technology is a virtual representation of a physical object or system that serves as its real-time digital counterpart, enabling seamless integration of physical and virtual worlds for data analysis and system monitoring. In lifting equipment applications, digital twins model cranes, hoists, and other lifting systems, providing dynamic, data-rich virtual replicas that evolve with their physical counterparts.

The market momentum behind this technology reflects its transformative potential. According to industry projections, the global digital twin market will grow from $21.14 billion in 2025 to $149.81 billion by 2030, representing a remarkable 47.9% CAGR. The industrial cranes market is expected to reach $17.38 billion by 2033 at a 5.1% CAGR, while smart construction equipment market growth accelerates at 12.8% CAGR from 2024 to 2032.

This section explores how digital twins function in lifting operations, examines equipment types that benefit most, and identifies core system components essential for implementation.

How Does a Digital Twin Work in the Context of Lifting Equipment?

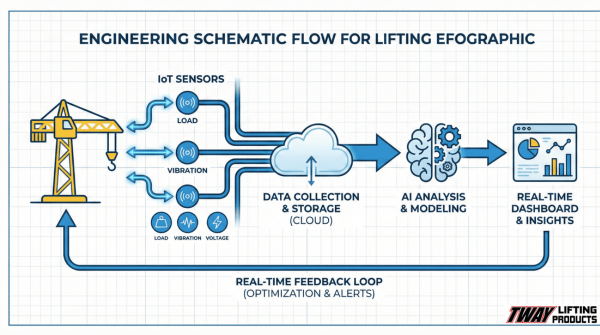

A digital twin in lifting equipment works through IoT sensors that collect real-time data including motor health through current and voltage monitoring, load dynamics via weight sensors and angle detection, and vibration analysis using accelerometers. AI algorithms detect anomalies in motor performance data to enable preventive maintenance before failures occur.

The technology enables continuous real-time monitoring of lifting operations by comparing actual conditions to planned parameters and alerting operators to potential hazards. This creates a feedback loop where physical equipment performance directly updates the virtual model, allowing for immediate optimization and risk mitigation.

What Types of Lifting Equipment Can Benefit From Digital Twins?

The types of lifting equipment that benefit from digital twins include harbor cranes, industrial cranes, hoists, and spreader bar technology, all of which can integrate IoT sensors for real-time data collection and predictive maintenance. Harbor cranes demonstrate particularly successful implementations, with Liebherr achieving 600 tons per hour throughput using their Smart Grip system.

Industrial lifting systems benefit through enhanced safety monitoring, load optimization, and maintenance scheduling. Spreader bar technology gains precision in load distribution analysis and structural stress monitoring through digital twin integration.

What Are the Core Components of a Digital Twin for Lifting Equipment?

The core components of a digital twin for lifting equipment are IoT sensors for data collection, simulation and modeling capabilities for creating virtual representations, and AI/ML algorithms for predictive analytics. Integration requires telemetry systems for tracking operational hours and comprehensive lifecycle management.

Security represents a critical component layer, with data encryption and robust access control measures serving as essential protective elements. These components work together to create a comprehensive digital ecosystem that mirrors physical equipment behavior while providing actionable insights for optimization and maintenance planning.

How Can Digital Twin Technology Improve the Design Process for Lifting Equipment?

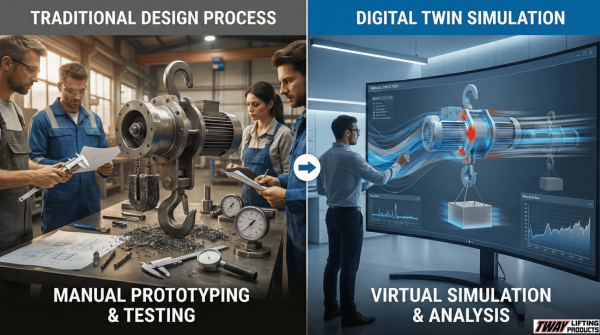

Digital twin technology improves the design process for lifting equipment by creating virtual replicas that enable comprehensive testing and optimization before physical manufacturing. According to manufacturing industry studies, digital twins enable up to 50% reduction in development time for manufacturing companies. The technology allows for simulation of various scenarios including different load conditions, weather patterns, and operational procedures before physical prototyping.

Digital twins transform traditional design workflows by replacing time-intensive physical testing with rapid virtual iterations. Engineers can validate structural integrity, optimize weight distribution, and test safety margins in simulated environments. This approach eliminates costly design revisions that typically occur during physical prototype testing. The following subsections explore specific design challenges, cost reduction mechanisms, and customization capabilities that digital twins bring to lifting equipment development.

What Design Challenges Can Be Addressed With Digital Twins?

Digital twins can simulate and verify lift plans to ensure compliance with ASME B30 safety standards for cranes, hoists, and rigging equipment. These virtual models address critical design challenges such as load capacity verification, structural stress analysis, and safety margin calculations under extreme conditions.

Key design challenges resolved through digital twin simulation include:

- Load distribution analysis across multiple lifting points

- Dynamic response testing under varying weather conditions

- Fatigue life prediction for critical structural components

- Operator visibility optimization for safe crane operation

According to industry frameworks, ISO 23247 provides a framework for creating and managing digital twins in manufacturing, ensuring interoperability and data consistency. This standardization enables seamless integration between design teams, manufacturers, and end users throughout the development process.

How Does Simulation With Digital Twins Reduce Prototyping Costs?

Simulation with digital twins reduces prototyping costs by enabling comprehensive virtual testing before building physical prototypes, significantly reducing material and labor costs. Companies can validate design concepts, test failure scenarios, and optimize performance parameters without expensive physical iterations.

Cost reduction occurs through several mechanisms:

- Elimination of multiple physical prototypes during design iterations

- Reduced material waste from failed prototype testing

- Shortened development timelines through parallel virtual testing

- Lower labor costs for physical assembly and disassembly

A 2021 industry collaboration between Liebherr partnered with Mevea to create complete 3D models of cranes and their environments, enabling real-time simulation and optimization without physical testing. This partnership demonstrated how virtual testing environments can replicate complex operational scenarios while maintaining design accuracy and safety validation.

How Can Digital Twins Enhance Customization of Lifting Equipment Designs?

Digital twins enhance customization of lifting equipment designs by enabling rapid iteration and testing of custom designs in virtual environments. Engineers can modify specifications, test performance parameters, and validate safety requirements for client-specific applications without lengthy physical prototyping cycles.

Customization capabilities include specialized load configurations, unique environmental requirements, and application-specific safety features. Digital twins allow designers to create virtual variants for different industries such as construction, manufacturing, or marine operations. Each variant can be tested and optimized independently before final specification approval.

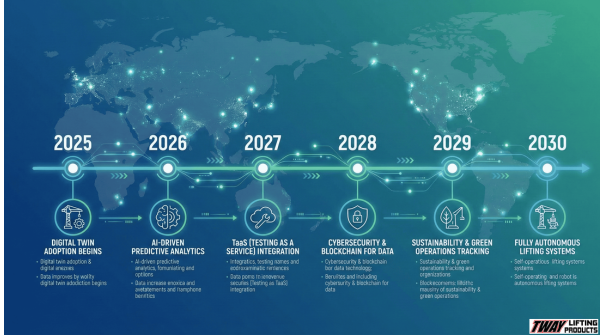

According to emerging business models, the technology supports Twin-as-a-Service (TaaS) business models, allowing companies to subscribe to digital twin solutions instead of building them from scratch. This approach makes advanced simulation capabilities accessible to smaller manufacturers and custom equipment designers who lack internal digital twin development resources.

The design process transformation continues as digital twin technology addresses maintenance and inspection challenges, creating a comprehensive approach to lifting equipment lifecycle management.

In What Ways Does Digital Twin Technology Enhance Maintenance and Inspection of Lifting Equipment?

Digital twin technology enhances maintenance and inspection of lifting equipment by providing real-time monitoring, predictive analytics, and automated documentation systems that significantly improve operational efficiency and safety outcomes. This technology delivers measurable improvements including a 20% reduction in unexpected work stoppages, 73% faster incident investigation times, and 60% reduction in documentation errors through automated digital tracking systems.

The integration of digital twins transforms traditional reactive maintenance approaches into proactive, data-driven strategies that predict equipment failures before they occur. This transformation enables maintenance teams to schedule interventions based on actual equipment condition rather than predetermined time intervals, resulting in optimal resource allocation and extended equipment lifecycles.

How Can Digital Twins Enable Predictive Maintenance for Lifting Gear?

Digital twins enable predictive maintenance for lifting gear through advanced sensor integration and AI-powered analytics that identify failure patterns before equipment breakdown occurs. Vibration analysis through accelerometers detects early failure symptoms by monitoring mechanical stress patterns and identifying deviations from normal operating parameters. AI-powered digital twins analyze vast amounts of operational data to identify subtle patterns and predict failures with high accuracy, enabling maintenance teams to address issues during planned downtime rather than emergency repairs.

Predictive maintenance scheduling operates through real-time IoT sensor data that continuously monitors equipment health parameters such as motor current, hydraulic pressure, and structural stress. This continuous monitoring approach prevents equipment failures by triggering maintenance alerts when sensor data indicates approaching failure thresholds, allowing operators to schedule repairs before catastrophic breakdowns occur.

What Role Do Digital Twins Play in Compliance and Safety Inspections?

Digital twins play a critical role in compliance and safety inspections by providing comprehensive documentation and proactive hazard identification that helps companies meet and exceed OSHA requirements. The technology supports a proactive approach to safety and compliance by maintaining detailed records of all operational parameters, maintenance activities, and safety incidents in a centralized digital format that simplifies regulatory reporting and audit processes.

Insurance cost reductions represent a significant benefit, with companies experiencing 12-18% average reduction in insurance premiums due to improved safety records and risk management capabilities. Virtual simulations identify potential hazards and optimize lift plans for maximum safety before actual operations commence, enabling safety teams to test various scenarios and identify optimal operating procedures without exposing personnel to risk during the planning phase.

How Do Digital Twins Help Diagnose Failures or Anomalies in Equipment?

Digital twins help diagnose failures or anomalies in equipment through real-time monitoring systems that compare actual operating conditions against planned parameters and historical performance data. Safe load indicator capabilities utilize weight sensors and angle detection to provide immediate anomaly detection when loads exceed safe operating limits or when equipment operates outside designed parameters.

Motor health monitoring through current and voltage analysis identifies performance degradation by tracking electrical consumption patterns and detecting variations that indicate bearing wear, electrical faults, or mechanical binding. Real-time comparison systems enable immediate detection of deviations by continuously analyzing sensor data streams and triggering alerts when operational parameters drift beyond acceptable ranges, allowing operators to address issues before they result in equipment failure or safety incidents.

This diagnostic capability transforms maintenance from reactive troubleshooting to proactive problem identification, enabling Tway Lifting and similar companies to deliver enhanced reliability and safety performance for their lifting equipment solutions nationwide.

What Are the Key Benefits and Limitations of Using Digital Twin Technology in Lifting Equipment?

Digital twin technology in lifting equipment delivers substantial operational improvements while presenting specific implementation challenges. Implementation delivers 20-30% improvement in capital and operational efficiency on large-scale infrastructure projects. The technology achieves 15% average reduction in carbon emissions, supporting sustainability goals across industrial operations.

The benefits span operational efficiency, safety enhancement, and cost reduction. However, organizations must navigate data integrity risks, legacy system integration challenges, and resource requirements. Organizations of different sizes face varying implementation barriers, though modern service models address many traditional constraints.

What Operational Efficiencies Can Digital Twins Bring to Lifting Operations?

Operational efficiencies from digital twins include significant cost reductions and performance optimization across lifting operations. Digital twins enable 10% reduction in labor costs through supply chain optimization. Liebherr’s Smart Grip system optimized cargo loading to achieve 600 tons per hour throughput, demonstrating real-world performance gains.

Key efficiency improvements include:

- Predictive maintenance reduces unplanned downtime and maintenance costs significantly

- Real-time operational monitoring optimizes load planning and execution

- Data-driven decision making minimizes operational delays

- Automated documentation reduces manual tracking overhead

These efficiencies translate to measurable ROI through reduced operational costs and increased equipment utilization rates.

What Potential Limitations or Challenges Exist When Adopting Digital Twins?

The limitations of digital twin adoption center on security vulnerabilities and technical integration barriers. Data integrity risks exist where malicious actors could potentially alter data, leading to incorrect decisions and catastrophic failures. Integration with legacy systems presents challenges as many older systems were not designed with digital connectivity in mind.

Critical implementation challenges include:

- Unauthorized access to digital twins could allow manipulation of systems, leading to operational disruptions or safety hazards

- High initial investment costs for comprehensive sensor networks and software infrastructure

- Staff training requirements for new technology adoption

- Data quality dependencies that require consistent sensor calibration and maintenance

Organizations must develop robust cybersecurity protocols and change management strategies to address these limitations effectively.

How Do Organizational Size and Resources Impact Digital Twin Implementation?

Organizational size and resources significantly influence digital twin implementation approaches and success rates. Modern platforms and strategic approaches can significantly reduce implementation costs for smaller organizations. Twin-as-a-Service (TaaS) models allow companies to subscribe to solutions rather than building from scratch, making the technology accessible across different organizational scales.

Implementation considerations by organization size:

- Large enterprises can justify custom development and comprehensive sensor networks

- Mid-size companies benefit from hybrid approaches combining off-the-shelf solutions with targeted customization

- Smaller organizations leverage cloud-based TaaS models to access advanced capabilities without major capital investment

- Resource allocation varies from dedicated IT teams to outsourced implementation partnerships

The democratization of digital twin technology through service models enables broader industry adoption regardless of organizational constraints.

How Is Digital Twin Technology Integrated With Other Digital Solutions in Lifting Operations?

Digital twin technology achieves its full potential when integrated with other digital solutions in lifting operations. These integrations create comprehensive ecosystems that enhance operational efficiency, predictive capabilities, and real-time decision-making across lifting equipment lifecycles.

Integration creates potential cybersecurity entry points that require multi-layered security approaches including threat modeling and penetration testing. The following sections explore how digital twins connect with IoT devices, asset management systems, and the security considerations essential for safe implementation.

How Do IoT Devices Enhance the Functionality of Digital Twins?

IoT devices provide the foundation for digital twins by collecting real-time data on motor health, load dynamics, vibration patterns, and operational hours. Smart lifting systems integrate IoT sensors for continuous data collection, enabling predictive maintenance and reducing downtime across crane and hoist operations.

Key IoT integrations include:

- Motor health monitoring through current and voltage sensors

- Load dynamics tracking via weight sensors and angle detection

- Vibration analysis using accelerometers for early failure detection

- Operational hour logging for lifecycle management

Integrated telemetry systems enable comprehensive lifecycle management of equipment, creating data streams that feed directly into digital twin models for real-time analysis and prediction.

Can Digital Twins Be Combined With Asset Management Systems?

Digital twins integrate seamlessly with cloud services and existing management platforms to create comprehensive operational visibility. The technology supports interoperability through standards like ISO 23247, ensuring data consistency across systems and enabling unified asset tracking.

These integrations provide:

- Centralized asset performance monitoring across multiple sites

- Automated maintenance scheduling based on real-time condition data

- Comprehensive reporting for regulatory compliance and insurance requirements

- Cross-platform data sharing for enhanced decision-making

Cloud-based integration allows lifting equipment operators to access digital twin insights from anywhere, supporting remote monitoring and management of distributed lifting operations.

What Security Considerations Come With Integrating Digital Twins?

Key cybersecurity risks include data integrity threats, access control vulnerabilities, and integration vulnerabilities with IoT devices and cloud services. The interconnected nature of digital twin systems makes them vulnerable to cyberattacks requiring comprehensive security protocols.

A multi-layered security approach is essential, including:

- Threat modeling to identify potential attack vectors

- Penetration testing for vulnerability assessment

- Data encryption for information protection

- Robust access control measures with role-based permissions

- Network segmentation to isolate critical systems

- Regular security audits and updates

Digital twin integrations must balance connectivity benefits with security requirements to protect both operational data and physical equipment from cyber threats.

What Does the Future Hold for Digital Twins in the Lifting Equipment Industry?

The future for digital twins in the lifting equipment industry holds transformative potential, with market revenues expected to reach the high double-digit billion range by 2030. Digital twin technology is rapidly becoming an indispensable tool that will reshape how lifting equipment is designed, maintained, and operated across industrial applications.

This technological evolution encompasses three critical areas: emerging deployment trends that prioritize sustainability and service-based models, artificial intelligence integration that enhances predictive capabilities, and accelerating global adoption patterns driven by substantial market growth projections.

What Are the Emerging Trends in Digital Twin Technology for Lifting Equipment?

The emerging trends in digital twin technology for lifting equipment center on service-oriented deployment models, standardized integration frameworks, and sustainability-focused applications. Twin-as-a-Service (TaaS) is emerging as the dominant business model, allowing companies to access digital twin capabilities through subscription services rather than building complex systems from scratch.

Integration follows the ISO 23247 framework for standardization, ensuring interoperability between different digital twin systems and manufacturing processes. This standardization enables seamless data exchange and consistent implementation across various lifting equipment manufacturers and operators.

Sustainability has become a primary focus, with digital twins achieving an average 15% reduction in carbon emissions through optimized operations, predictive maintenance, and efficient resource utilization. These environmental benefits position digital twins as essential tools for companies meeting stricter environmental regulations and corporate sustainability goals.

How Could AI and Machine Learning Advance Digital Twin Capabilities?

AI and machine learning integration enhances digital twin predictive capabilities, enabling more accurate and autonomous decision-making for lifting equipment operations. AI-powered digital twins analyze vast amounts of sensor data to identify subtle patterns and predict equipment failures with significantly greater accuracy than traditional monitoring methods.

Machine learning algorithms continuously improve anomaly detection for preventive maintenance by learning from historical data patterns and real-time operational conditions. These systems become more precise over time, reducing false positives and ensuring maintenance interventions occur only when necessary.

Advanced AI integration enables autonomous optimization of lifting operations, automatically adjusting parameters based on load conditions, environmental factors, and equipment performance data to maximize efficiency while maintaining safety standards.

What Is the Outlook for Industry Adoption in the US and Globally?

The outlook for industry adoption shows remarkable growth, with the global digital twin market projected to grow from $21.14 billion in 2025 to $149.81 billion by 2030. The industrial cranes market is expected to reach $17.38 billion by 2033 with a 5.1% compound annual growth rate, while the smart construction equipment market is growing at 12.8% CAGR from 2024 to 2032.

US adoption is accelerating due to regulatory pressures for improved safety standards and the competitive advantage of predictive maintenance capabilities. Manufacturing companies are increasingly recognizing digital twins as essential for remaining competitive in global markets.

Global adoption varies by region, with developed markets leading implementation while emerging economies rapidly catching up through TaaS models that reduce initial investment barriers. This technological leap positions digital twins as the standard for modern lifting equipment operations worldwide.

How Should You Approach Implementing Digital Twin Technology in Lifting Equipment With Tway Lifting?

Implementing digital twin technology in lifting equipment requires strategic partnership with experienced providers who combine technical expertise with proven industry knowledge. This section examines how partnering with Tway Lifting can accelerate your digital transformation journey and outlines the key insights for successful implementation.

Can Tway Lifting Assist With Digital Twin Solutions for Design and Maintenance?

Tway Lifting assists with digital twin solutions by providing comprehensive smart lifting systems that integrate IoT sensors and real-time monitoring capabilities. The company has embraced digital twin technology as a premier source for lifting and rigging equipment in the United States, positioning itself at the forefront of industry innovation.

The company’s smart lifting systems integrate IoT sensors for real-time data collection, representing the future of spreader bar technology. These systems enable continuous monitoring of critical parameters such as load dynamics, motor health, and operational conditions. Tway Lifting’s approach combines traditional lifting expertise with cutting-edge technology adoption.

Tway Lifting’s digital twin capabilities enable continuous real-time monitoring of lifting operations, comparing actual conditions to planned parameters and alerting operators to potential hazards. The company focuses on custom engineering and compliance with industry standards such as ASME B30, ensuring that digital twin implementations meet both safety requirements and operational objectives.

This comprehensive approach positions Tway Lifting as a strategic partner for organizations seeking to implement digital twin technology while maintaining focus on safety and regulatory compliance.

What Are the Key Takeaways About Using Digital Twin Technology in Lifting Equipment Design and Maintenance We Covered?

The key takeaways about digital twin technology demonstrate substantial benefits across operational, safety, and financial metrics. Digital twins provide significant ROI through 20% reduction in unexpected work stoppages and up to 50% reduction in development time, making them essential for competitive advantage.

Safety improvements include 73% faster incident investigation and 12-18% reduction in insurance premiums. These metrics represent measurable improvements in both risk management and operational efficiency. A 2021 industry analysis revealed that companies implementing digital twins achieve 20-30% improvement in capital and operational efficiency on large-scale infrastructure projects.

Implementation requires addressing cybersecurity risks and integration challenges with legacy systems. Organizations must develop multi-layered security approaches including threat modeling, penetration testing, and robust access control measures. The interconnected nature of digital twin systems creates potential vulnerabilities that demand comprehensive security protocols.

Future growth driven by AI/ML integration and Twin-as-a-Service business models will reshape the industry landscape. The global digital twin market is projected to grow from $21.14 billion in 2025 to $149.81 billion by 2030, with a CAGR of 47.9%. Companies like Tway Lifting are well-positioned to lead the industry into a safer, more efficient, and more profitable future through strategic technology adoption and proven expertise.

The convergence of digital twin technology with traditional lifting operations represents a fundamental shift toward predictive, data-driven maintenance and design practices that deliver measurable improvements across all operational metrics.