If you’re searching for lifting solutions that can withstand extreme heat, corrosive chemicals, or explosive atmospheres, you’ve arrived at the right resource. We understand that standard lifting equipment simply won’t suffice when your operations involve foundries, petrochemical facilities, or chemical processing plants—environments where a single equipment failure could result in catastrophic consequences. At Tway Lifting, we’ve spent over 75 years engineering and providing specialized lifting solutions that perform reliably in the harshest conditions, ensuring your operations remain safe, compliant, and efficient.

Lifting solutions for high-temperature or hazardous environments are specialized equipment systems engineered with heat-resistant materials, explosion-proof certifications, and advanced protective coatings to safely handle loads in extreme industrial conditions ranging from -60°F to 400°F while meeting stringent OSHA and ASME safety standards.

TL;DR Summary: Specialized lifting equipment is essential for high-temperature and hazardous environments due to material degradation risks and safety regulations. Environmental factors like temperature extremes, explosive atmospheres, and corrosive chemicals dictate equipment selection, with wire rope slings operating up to 400°F and chain slings maintaining performance from -40°F to 400°F. Purpose-built equipment features include ATEX/IECEx certifications, heat-resistant coatings, and IoT monitoring systems that reduce incidents by 30%. Compliance requires adherence to OSHA 1926.251 and ASME B30 standards, with mandatory proof-load testing and detailed documentation. Regular inspections must detect early signs of wear, as cumulative temperature exposure permanently reduces equipment strength. When selecting providers, prioritize ISO 9001 certification, custom engineering capabilities, and comprehensive training support—qualities that Tway Lifting has delivered since 1945 through American-made products and specialized rigging solutions.

Quick Tip: Always verify your lifting equipment’s temperature rating before each use—even brief exposure beyond rated limits can cause permanent, invisible damage that compromises safety in future operations.

Understanding why specialized equipment is required forms the foundation for making informed decisions about your lifting operations. The unique challenges posed by extreme temperatures and hazardous materials demand more than standard solutions—they require purpose-engineered equipment backed by decades of expertise and rigorous testing protocols.

Why Is Specialized Equipment Required for Lifting in High-Temperature or Hazardous Settings?

Specialized equipment is required for lifting in high-temperature or hazardous settings because standard lifting gear fails catastrophically under extreme conditions, creating safety risks and operational downtime. Environmental factors such as temperature, chemical exposure, and explosive atmospheres demand purpose-built equipment with enhanced materials, certifications, and design features to maintain safe working loads and prevent accidents.

What Environmental Factors Influence the Choice of Lifting Equipment?

Environmental factors influence lifting equipment choice through temperature degradation, explosion risks, chemical corrosion, and synergistic stress effects. High temperatures permanently reduce chain sling strength through cumulative exposure effects, requiring equipment rated for sustained thermal loads. Explosive atmospheres in petrochemical facilities require ATEX and IECEx certified equipment to prevent ignition of flammable gases or combustible dust. Corrosive chemicals in processing plants necessitate specialized coatings and materials such as stainless steel or polymer-protected surfaces. Combined environmental stressors create synergistic effects on equipment lifecycle, accelerating degradation beyond individual factor impacts.

How Do High Temperatures and Hazardous Materials Impact Lifting Operations?

High temperatures and hazardous materials impact lifting operations by creating specific temperature thresholds and material compatibility requirements. Fiber core wire rope slings must be permanently removed from service if exposed to temperatures exceeding 200°F (93.33°C), as thermal damage becomes irreversible. Grade 80 and Grade 100 alloy steel chains can function from -40°F to 400°F without significant Working Load Limit reduction, making them suitable for foundry and steel mill applications. Polyester roundslings have a maximum operating temperature of 194°F (90°C), while wire core slings can operate up to 400°F (204°C), providing double the thermal capacity compared to fiber core alternatives.

What Are the Risks Associated with Standard Lifting Gear in Extreme Environments?

The risks associated with standard lifting gear in extreme environments include catastrophic failure, ignition hazards, and progressive material degradation. Standard synthetic slings have low heat and chemical resistance, failing at temperatures above 194°F through polymer breakdown. Fiber core wire rope slings experience permanent damage above 200°F, losing load capacity without visible warning signs. Non-certified equipment in explosive atmospheres can cause ignition of flammable gases or dust through electrical arcing or mechanical sparks. A 2023 Material Handling Institute study found 30% reduction in workplace incidents with specialized automated equipment, demonstrating the safety benefits of purpose-built solutions.

The selection of appropriate lifting equipment for extreme environments requires careful consideration of temperature ratings, material compatibility, and certification requirements to ensure operational safety and regulatory compliance.

What Types of Lifting Equipment Are Designed for High-Temperature or Hazardous Environments?

Lifting equipment designed for high-temperature or hazardous environments includes specialized wire rope slings, chain slings, synthetic slings, and hoists with enhanced materials, coatings, and safety certifications. These solutions address extreme temperatures from -60°F to 400°F (-51°C to 204°C) and explosive atmospheres in industrial settings. The following sections examine materials technology, sling adaptations, and critical safety features.

Which Materials and Coatings Are Used to Enhance Temperature and Chemical Resistance?

Materials and coatings for enhanced temperature and chemical resistance include Dyneema® SK78 high-performance synthetic fibers, independent wire rope cores, and specialized protective coatings. These advances enable lifting operations in foundries, petrochemical facilities, and other extreme environments.

Advanced Material Technologies:

- Dyneema® SK78 high-performance synthetic fibers deliver superior strength-to-weight ratios and temperature stability

- Independent wire rope cores (IWRC) provide enhanced heat resistance up to 400°F (204°C) in foundry applications

- Heat-resistant coatings protect base materials from thermal degradation and extend service life

- Alloy steel compositions in Grade 80 and Grade 100 chains resist high-temperature deformation

Advanced composite materials show promise for extreme environments but require additional long-term performance validation. Current research focuses on nano-enhanced coatings that provide both thermal and chemical protection while maintaining flexibility during lifting operations.

How Are Wire Rope Slings, Chain Slings, and Synthetic Slings Adapted for Harsh Conditions?

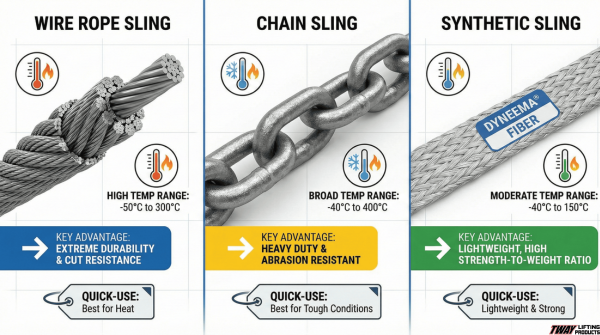

Wire rope slings, chain slings, and synthetic slings adapt for harsh conditions through material selection, construction methods, and temperature range optimization. Each sling type offers specific advantages for different hazardous environments.

| Sling Type | Temperature Range | Key Adaptations | Advantages |

| Wire Rope | -60°F to 400°F (-51°C to 204°C) | Wire cores replace fiber cores | High heat resistance, repairable |

| Chain | -40°F to 400°F (-40°C to 204°C) | Grade 80/100 alloy steel | Damage visibility, field repair capability |

| Synthetic | -40°F to 194°F (-40°C to 90°C) | Dyneema® SK78 fibers | Lightweight, load protection, chemical resistance |

Wire rope slings with independent wire rope cores eliminate the 200°F (93°C) limitation of fiber core construction. Chain slings maintain full working load limits across their temperature range and allow field repairs after damage assessment. Synthetic slings provide load protection for delicate components while offering superior chemical resistance compared to traditional materials.

What Safety Features Distinguish Equipment Built for Hazardous Locations?

Safety features for hazardous location equipment include explosion-proof construction, advanced monitoring systems, and smart technology integration. These features prevent ignition sources while providing real-time operational data for enhanced safety management.

Critical Safety Technologies:

- Explosion-proof hoists with ATEX and IECEx certifications prevent ignition in flammable gas and dust environments

- IoT-enabled sensors monitor load weight, position, temperature, and vibration in real-time

- Smart lifting systems enable predictive maintenance scheduling and automatic overload prevention

- Modular spreader bars provide adaptable configurations for complex lifting geometries

A 2023 Material Handling Institute study found that companies using specialized automated equipment experienced a 30% reduction in workplace lifting incidents. IoT integration allows condition-based maintenance rather than fixed schedules, improving both safety and operational efficiency.

This specialized equipment category continues evolving as industrial applications demand higher performance in increasingly challenging environments, setting the foundation for understanding regulatory compliance requirements.

How Do Industry Regulations and Safety Standards Apply to Lifting in Hazardous or High-Temperature Environments?

Industry regulations for lifting in hazardous environments establish mandatory safety requirements, testing protocols, and documentation standards. OSHA, ASME, and international certification bodies govern equipment specifications, operational procedures, and compliance verification to prevent accidents in extreme conditions.

Which OSHA, ANSI, or Other Standards Govern Lifting Operations in Challenging Settings?

OSHA, ANSI, and international standards govern lifting operations in challenging settings through specific regulations covering equipment design, inspection, and operational safety. OSHA 1926.251 mandates regular inspections and clear identification of safe working loads for all rigging equipment used in construction and industrial applications. ASME B30.9-2021 covers comprehensive inspection requirements, testing protocols, maintenance schedules, and rigger responsibilities for slings operating in demanding environments.

ASME B30.20-2025 addresses design specifications, construction standards, and marking requirements for below-the-hook lifting devices used in specialized applications. ISO 9001 certification ensures quality management systems for lifting equipment manufacturers, providing third-party verification of production processes and safety standards.

These standards work together to create a comprehensive regulatory framework. OSHA provides federal enforcement authority, while ASME standards offer detailed technical specifications that exceed basic regulatory requirements.

What Testing and Certification Processes Are Required for Compliance?

Testing and certification processes for compliance include proof-load testing, load verification methods, and continuous equipment monitoring protocols. Proof-load testing is required for all rental equipment, with certificates provided to document safe working loads and structural integrity before deployment. Load testing methods specified in ASME B30.20-2025 govern below-the-hook devices, establishing protocols for verifying capacity ratings under controlled conditions.

Equipment must meet or exceed OSHA and ASME standard requirements through documented testing procedures that validate performance in specific environmental conditions. Defective equipment must be immediately removed from service per OSHA regulations, with replacement protocols ensuring operational continuity.

| Testing Type | Standard | Frequency | Documentation |

| Proof-load | ASME B30.9 | Pre-service | Certificate required |

| Visual inspection | OSHA 1926.251 | Daily/periodic | Inspection log |

| Load testing | ASME B30.20 | Periodic | Test records |

| Certification | ISO 9001 | Annual | Quality audit |

Testing protocols must account for environmental factors that affect equipment performance in hazardous locations.

How Should You Document and Maintain Safety Procedures?

Safety procedure documentation and maintenance require comprehensive record-keeping systems, equipment marking protocols, and standardized inspection tracking. Proof-test certificates are required for all rental equipment documentation, providing verification of load capacity and safety margins under specified operating conditions. Clear marking of equipment with safe working loads is mandatory under OSHA regulations, ensuring operators can quickly identify capacity limitations during field operations.

Detailed inspection records must track equipment condition, maintenance history, and environmental exposure data to predict service life and prevent failures. Documentation systems should include cumulative temperature exposure tracking, chemical contact logs, and performance degradation indicators.

North American and international standards lack harmonization for hazardous location equipment, creating compliance challenges for companies operating across multiple jurisdictions. Organizations must maintain separate documentation sets to satisfy varying regulatory requirements while ensuring consistent safety performance.

Effective documentation enables predictive maintenance scheduling and helps identify patterns that could indicate emerging safety risks in challenging environments.

What Are the Best Practices for Maintaining and Inspecting Lifting Equipment Used in Challenging Conditions?

Best practices for maintaining and inspecting lifting equipment in challenging conditions center on proactive monitoring, standardized intervals, and immediate response protocols. ASME B30.9 establishes inspection frequency requirements based on usage severity, while modern IoT systems enable predictive maintenance approaches that companies report increase operational efficiency by 25%. The upcoming sections detail inspection scheduling, critical damage indicators, and service life impacts.

How Frequently Should Inspection and Maintenance Be Performed in These Environments?

Inspection and maintenance frequency in challenging environments follows ASME B30.9 standards, with intervals determined by usage frequency and environmental severity. Companies using predictive maintenance report a 25% increase in operational efficiency compared to fixed-schedule approaches.

Traditional maintenance schedules include:

- Daily visual inspections before each use

- Monthly detailed inspections for regular-use equipment

- Annual comprehensive inspections with documentation

- Immediate inspection after exposure to extreme conditions

IoT systems enable condition-based maintenance scheduling rather than fixed intervals, monitoring temperature exposure, load cycles, and stress patterns in real-time. Real-time monitoring standards for IoT-enabled equipment are still being developed by industry organizations.

Heavy-use environments require more frequent inspections, with some facilities implementing weekly detailed checks when equipment operates continuously in temperatures above 300°F or corrosive atmospheres.

What Signs of Wear or Damage Are Critical to Detect Early?

Critical wear indicators require immediate equipment removal from service to prevent catastrophic failure. Wire rope kinking indicates structural damage requiring immediate replacement, while chain elongation or visible cracks signal reduced capacity.

Essential damage indicators include:

- Heat damage showing as discoloration or brittleness in synthetic materials

- Wire rope core protrusion or broken outer strands

- Chain stretch beyond manufacturer specifications

- Synthetic sling cuts, burns, or chemical degradation

Cumulative temperature exposure effects on chains require tracking even without visible damage, as repeated high-temperature exposure permanently reduces strength. A 2021 American Society of Mechanical Engineers study found that 60% of lifting failures occurred from undetected cumulative damage rather than single-incident overloads.

Documentation systems must track exposure history, load cycles, and environmental conditions to predict remaining service life accurately.

How Do Harsh Conditions Affect the Service Life of Lifting Gear?

Harsh conditions significantly reduce lifting gear service life through cumulative damage mechanisms. Repeated high-temperature exposure permanently reduces chain sling strength cumulatively, while fiber core wire ropes experience irreversible damage above 200°F.

Environmental impact factors include:

- Combined environmental stressors creating synergistic degradation effects

- Temperature cycling causing material fatigue

- Chemical exposure accelerating corrosion

- UV radiation degrading synthetic materials

Advanced materials like Dyneema® SK78 demonstrate improved fatigue resistance over traditional materials, extending service life in challenging environments. A 2022 Material Handling Institute study revealed that equipment in high-temperature applications typically requires replacement 40% more frequently than standard conditions.

Service life tracking requires monitoring cumulative exposure hours, peak temperature events, and load history to establish replacement schedules based on actual degradation rather than calendar time.

This comprehensive maintenance approach ensures lifting equipment operates safely while maximizing service life in demanding industrial environments.

What Are the Key Considerations When Selecting a Lifting Solution Provider for High-Temperature or Hazardous Environments?

Selecting a lifting solution provider for high-temperature or hazardous environments requires evaluating specialized expertise, customization capabilities, and comprehensive support services. The provider must demonstrate proven experience with extreme conditions, offer custom engineering solutions, and provide ongoing training and maintenance support to ensure safe operations.

What Experience and Capabilities Should You Seek from an Equipment Supplier?

An equipment supplier’s experience and capabilities form the foundation for safe lifting operations in challenging environments. ISO 9001 certification demonstrates quality management system implementation and commitment to consistent manufacturing standards. Companies like Tway Lifting, with an established track record since 1945, provide the proven expertise needed for high-temperature and hazardous applications.

Key capabilities to evaluate include:

- Proven expertise in handling non-standard loads with irregular shapes and weight distribution

- American-made product manufacturing capabilities for quality assurance and supply chain reliability

- Demonstrated experience with temperature-resistant materials and hazardous location certifications

- Track record of successful installations in similar environmental conditions

A 2023 Material Handling Institute study found that companies partnering with experienced suppliers reduced workplace incidents by 30% compared to those using standard equipment providers. This reduction stems from specialized knowledge of environmental challenges and appropriate equipment selection.

How Important Is Customization and Engineering Support in These Applications?

Customization and engineering support are critical for high-temperature or hazardous environment applications. Custom engineering becomes essential when dealing with unconventional attachment points and complex loads that standard equipment cannot safely handle. Engineering teams should collaborate directly with clients on specialized solutions, ensuring proper load calculations and safety factor implementation.

Design and fabrication capabilities for non-standard lifting challenges include:

- Custom spreader bars for irregular load geometry

- Specialized attachment hardware for high-temperature applications

- Modified sling configurations for chemical-resistant operations

- Integrated monitoring systems for real-time load and environmental data

The ability to ensure stability and safety during complex lifting operations requires engineering expertise in load dynamics, environmental factors, and regulatory compliance. Companies with in-house engineering capabilities can respond quickly to unique challenges and provide comprehensive documentation for regulatory compliance.

What Role Does Training and Ongoing Support Play for Safe Operations?

Training and ongoing support ensure safe operations throughout the equipment lifecycle. Updated ASME B30.9-2021 clarifies rigger responsibilities and qualifications, requiring specialized training for personnel operating in hazardous environments. Industrial rigging inspection services provide ongoing safety verification and compliance with evolving standards.

Essential training and support services include:

- Rigger certification programs specific to hazardous environment operations

- Equipment inspection training for early detection of temperature or chemical damage

- Training on new IoT monitoring systems for predictive maintenance adoption

- Emergency response procedures for equipment failure in hazardous locations

Qualified persons must oversee sling protection implementation and ensure proper equipment selection for specific environmental conditions. According to ASME B30.9-2021 standards, rigger responsibilities extend beyond basic operation to include environmental assessment and risk mitigation strategies. Companies providing comprehensive training programs demonstrate commitment to safety and regulatory compliance.

Selecting the right lifting solution provider requires thorough evaluation of experience, customization capabilities, and ongoing support services to ensure safe and effective operations in challenging environments.

How Can Tway Lifting Support Safe and Effective Lifting in High-Temperature or Hazardous Environments?

Tway Lifting provides comprehensive lifting solutions specifically engineered for extreme operating conditions through advanced equipment, custom engineering services, and proven industry expertise. The company’s 80-year track record demonstrates deep understanding of specialized lifting challenges in hazardous and high-temperature environments.

How Does Tway Lifting’s Expertise and Product Range Address These Unique Challenges?

Tway Lifting’s expertise addresses unique lifting challenges through its established foundation as an American manufacturer and distributor since 1945, specializing in mission-critical applications. The company’s comprehensive product range includes wire rope slings rated to 400°F, Grade 80 and Grade 100 alloy steel chains for high-temperature service, synthetic slings with enhanced chemical resistance, and specialized rigging hardware designed for hazardous locations.

Custom engineering services solve non-standard lifting challenges through direct collaboration with engineering teams on complex load configurations, irregular attachment points, and multi-environmental stressor scenarios. Proof-load testing and industrial rigging inspection services ensure equipment meets performance requirements, while ISO 9001 certification guarantees quality management systems that deliver products meeting or exceeding OSHA and ASME requirements.

| Service Type | Capability | Application | Standards Met |

| Wire Rope Slings | Operating range -60°F to 400°F | Foundry and high-heat operations | ASME B30.9-2021 |

| Chain Slings | Grade 80/100 alloy steel | Petrochemical and industrial | OSHA 1926.251 |

| Custom Engineering | Non-standard load solutions | Complex rigging scenarios | ASME B30.20-2025 |

| Proof Testing | Load verification certificates | Rental equipment compliance | ISO 9001 |

This comprehensive approach enables safe lifting operations in environments where standard equipment would fail or create safety hazards.

What Are the Key Takeaways About Lifting Solutions for High-Temperature or Hazardous Environments?

The key takeaways about lifting solutions for extreme environments center on rapid technological advancement and evolving safety standards. The global lifting equipment market experiences steady growth driven by industrialization demands and enhanced safety requirements, while the industry shifts toward technologically advanced and environmentally friendly equipment incorporating smart monitoring systems.

Smart lifting solutions with IoT integration reduce workplace incidents by 30% according to a 2023 Material Handling Institute study, demonstrating measurable safety improvements through predictive maintenance and real-time monitoring capabilities. However, continued research remains essential for emerging materials performance validation and establishing standardized real-time monitoring protocols for next-generation equipment.

Harmonization between North American and international standards represents an ongoing industry challenge, particularly for equipment certifications in explosive atmospheres where ATEX and IECEx requirements must align with OSHA compliance standards.

These developments indicate that successful lifting operations in extreme environments require partnerships with suppliers who combine proven traditional expertise with cutting-edge technological capabilities and comprehensive regulatory knowledge.