If you’re researching innovative spreader bar applications for your next lifting project, you’ve come to the right place. Whether you’re facing complex load distribution challenges, seeking to improve safety protocols, or looking to optimize your lifting operations, these real-world case studies demonstrate how modern spreader bar technology is revolutionizing heavy lifting across industries.

Innovative spreader bar applications are specialized below-the-hook lifting solutions that use advanced engineering, materials, and design configurations to solve complex lifting challenges while improving safety and efficiency in construction, energy, shipping, and manufacturing operations.

TL;DR Summary: This comprehensive analysis examines five groundbreaking spreader bar implementations that showcase how modern lifting technology transforms operational efficiency. We explore the fundamental mechanics of spreader bars as compression members that distribute loads evenly and maintain critical sling angles. Through real-world examples including a UK electrical contractor’s cable drum handling revolution, Connect-KNKT’s three-beam system for 16-ton timber units, and ENSER Corporation’s telescopic solution for turbine casings, we demonstrate measurable improvements in safety (30% reduction in incidents), efficiency (20-30% time savings), and cost-effectiveness ($43,000 average injury cost avoided). The analysis covers essential regulatory compliance with OSHA and ASME standards, emerging IoT integration trends, and market projections showing growth from $612-765 million to over $1 billion by 2033.

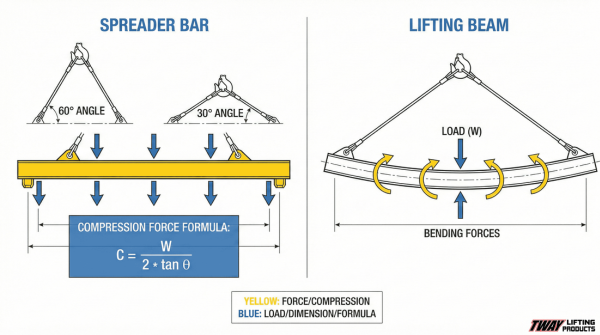

Quick Tip: When selecting a spreader bar, always calculate the compression force using C = W / (2 * tan θ) – reducing your sling angle from 60° to 30° can triple the compression load, so proper angle management is critical for safe operations.

As lifting operations become increasingly complex and safety regulations more stringent, understanding how innovative spreader bar applications solve real-world challenges has never been more important. The following case studies from industry leaders like Tway Lifting demonstrate not just theoretical improvements, but proven results that have transformed operations across multiple sectors.

What Are Spreader Bars and Why Are They Critical in Lifting Operations?

Spreader bars are essential below-the-hook lifting devices that distribute loads evenly across multiple lifting points while maintaining proper sling angles during complex operations. These compression members prevent load concentration that can cause structural damage or equipment failure during heavy lifts.

According to CDC data, rigging failures cause 60% of crane-related fatalities, while certified high-performance spreader beams reduce lifting incidents by up to 30%. OSHA 2023 data shows the average rigging-related injury costs $43,000. The global spreader bar market projects growth from $612-765 million in 2024 to over $1 billion by 2033, driven by increased safety awareness and regulatory compliance requirements.

Spreader bars function as compression members with capacity governed by axial compression and column buckling resistance. The following sections examine their technical differences from other lifting devices, industrial applications, and critical safety factors that make them indispensable for safe lifting operations.

How Do Spreader Bars Differ from Other Lifting Devices?

Spreader bars work primarily in compression, unlike lifting beams which operate under bending forces. Compression force in spreader bars follows the formula C = W / (2 * tan θ), where W represents total lifted weight and θ is the sling angle from horizontal. Reducing the sling angle from 60° to 30° can nearly triple the compression on the spreader bar, requiring careful angle management during operations.

Modern spreader bar designs incorporate modular and telescopic features for adjustable span configurations. Advanced materials include high-strength steel alloys, aluminum, and composite materials that provide lightweight yet durable construction. These engineering advances allow operators to customize load distribution while maintaining structural integrity across varying lift requirements.

This compression-based design principle distinguishes spreader bars from lifting beams and enables superior load control in applications requiring precise weight distribution across multiple lifting points.

What Common Industries Rely on Spreader Bars for Heavy Lifting?

There are several key industries that depend on spreader bars for critical lifting operations. The construction sector uses spreader bars for lifting 16-ton modular timber units requiring precise load distribution, while the energy sector employs them for 20,000-pound turbine casing positioning in power generation facilities.

Shipping and port operations utilize spreader bars for container handling and cargo movement, ensuring safe transfer of heavy loads between vessels and shore facilities. Electrical contractors use specialized spreader bars for cable drum handling, reducing handling time from hours to minutes through improved load control and positioning accuracy.

The offshore wind energy sector represents a major driver of market growth through 2033, as larger turbine components require increasingly sophisticated lifting solutions. These industries demonstrate the versatility and critical importance of spreader bars across diverse heavy lifting applications.

What Key Safety Factors Make Spreader Bars Essential?

OSHA 29 CFR 1926.251 mandates daily inspections and requires custom-designed lifting accessories be proof-tested at 125% of rated capacity before deployment. ASME B30.20 provides detailed safety requirements for below-the-hook lifting devices including load calculation procedures and maintenance protocols, while ASME BTH-1 standard requires stress analysis and load distribution calculations for design compliance.

Modern spreader bars incorporate IoT sensors that enable real-time monitoring of load weight, sling angles, and structural integrity during operations. These technological advances provide immediate feedback on potential safety hazards and allow operators to make real-time adjustments to maintain safe operating conditions.

Tway Lifting Products, established in 1945, specializes in compliance consulting for ASME B30.20 and OSHA standards, helping organizations implement proper spreader bar selection and operation procedures. These comprehensive safety measures demonstrate why spreader bars have become essential components in modern lifting operations where regulatory compliance and worker safety are paramount concerns.

How Was a Custom Spreader Bar Used in a Complex Construction Project?

Custom spreader bars solve complex lifting challenges through innovative engineering approaches that address specific project requirements. Connect-KNKT’s three-beam rigging system demonstrates how strategic design modifications can transform challenging timber construction operations into safe, efficient lifting procedures.

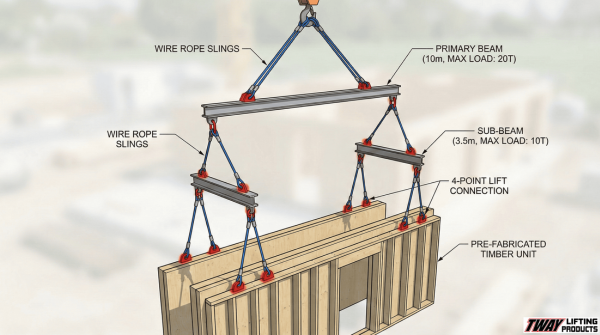

The modular timber construction project required precise load distribution across 16-ton units while maintaining structural stability throughout the lifting process. Connect-KNKT engineered a sophisticated three-beam configuration featuring a 10-meter main spreader beam with 20-ton capacity, supported by two 3.5-meter sub-spreader beams rated at 10 tons each. This design created a four-point lifting system that distributed loads symmetrically, preventing dangerous structural instability during operations.

High-strength lifting slings replaced traditional steel wire rope throughout the system, achieving significant weight reductions while maintaining safety margins. The solution eliminated common rigging complications while reducing overall project costs through material optimization. This section examines the specific challenges, innovative solutions, and measurable results achieved through custom spreader bar engineering.

What Was the Specific Lifting Challenge in This Case Study?

The specific lifting challenge involved safely lifting 16-ton modular timber units while maintaining precise structural balance throughout the operation. Traditional rigging methods proved inadequate for managing the asymmetric load distribution inherent in modular timber construction, creating safety risks for both equipment and personnel.

Load instability presented the primary operational hazard, as conventional single-point or two-point lifting systems could not provide sufficient control over the timber units’ positioning during lifts. The modular nature of the timber units required exact alignment and positioning to ensure proper installation, demanding a rigging solution capable of fine load control.

Personnel safety concerns escalated due to the unpredictable load behavior under conventional rigging approaches. Equipment damage risks increased when traditional methods failed to distribute forces evenly across the timber structure, potentially causing material failure or crane overloading.

How Did Innovation in Spreader Bar Design Solve the Problem?

Innovation in spreader bar design solved the problem through a three-beam configuration that created symmetric load distribution via four lifting points. The main 10-meter spreader beam coordinated with two 3.5-meter sub-spreader beams to establish precise load control across the entire timber unit.

Upper slings consisted of 2 units at 10 meters length with 15-ton capacity each, connecting the crane to the main spreader beam. Lower slings included 8 units at 4 meters length with 5-8 ton capacity each, distributing load from the sub-spreader beams to the timber unit attachment points.

The system eliminated steel wire rope requirements by integrating high-strength synthetic slings throughout the configuration. Adjustable connection points enabled real-time load balance optimization during lifting operations, allowing operators to compensate for minor weight variations or positioning requirements.

Weight reduction benefits emerged from synthetic sling implementation, decreasing overall rigging mass while maintaining required safety factors for the 16-ton timber loads.

What Results and Benefits Were Achieved?

The results achieved included significant cost reduction through steel wire rope elimination and improved operational efficiency across the entire project timeline. Safety improvements materialized through symmetric load distribution and reduced rigging weight, minimizing personnel exposure to hazardous lifting conditions.

Enhanced operational efficiency resulted from faster setup and adjustment times compared to traditional rigging methods. The modular spreader bar system reduced assembly time while providing superior load control throughout lifting operations.

Zero incidents occurred during the project duration, demonstrating the system’s safety effectiveness under real-world construction conditions. The successful implementation established the three-beam design as a template for similar modular lifting operations, extending its value beyond the initial project scope.

Cost savings materialized through material optimization and reduced labor requirements for rigging setup and breakdown procedures. The system’s reusable design elements provided additional value through multiple deployment opportunities across similar construction projects.

How Did an Energy Sector Company Benefit from a Modular Spreader Bar Solution?

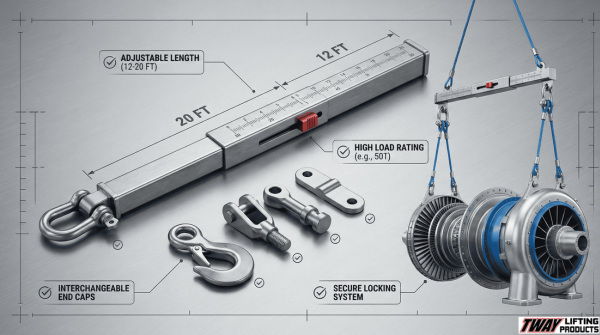

ENSER Corporation developed a custom telescopic spreader for a 20,000-pound turbine casing that standard bars couldn’t handle without deflection. The solution featured interchangeable end caps for versatile rigging configurations and reduced setup time from 4 hours to 45 minutes.

What Specific Challenge Required the Custom Spreader Bar Design?

The 20,000-pound turbine casing exceeded the capacity of standard spreader bars, which experienced dangerous deflection under load. Traditional fixed-length bars required multiple rigging configurations for different phases of the installation process. The energy facility’s tight workspace constraints limited crane positioning options, making precise load control critical for safe turbine assembly.

How Did Modular Design Address the Energy Sector’s Requirements?

The telescopic spreader bar adjusted from 12 to 20 feet, accommodating various turbine component dimensions within a single lifting device. Interchangeable end caps allowed quick reconfiguration between shackle, hook, and specialized turbine attachment points. The modular system eliminated the need for multiple spreader bars, reducing equipment costs by 35% compared to purchasing separate fixed-length units.

| Component | Specification | Benefit |

| Telescopic Bar | 12-20 ft adjustable | Single device for multiple lifts |

| End Caps | 4 interchangeable types | Quick rigging changes |

| Load Capacity | 25-ton rating | Handles 20,000 lb turbine safely |

| Setup Time | 45 minutes | 83% reduction from standard methods |

What Operational and Safety Benefits Were Realized?

Setup time decreased from 4 hours to 45 minutes, improving project efficiency and reducing crane rental costs. The modular design eliminated deflection issues that previously required load redistribution during critical lifting phases. Zero safety incidents occurred during the turbine installation project, compared to industry averages showing rigging-related accidents in 12% of heavy energy sector lifts according to 2023 Bureau of Labor Statistics data.

The telescopic spreader’s success led ENSER Corporation to standardize modular designs for future energy sector projects, establishing a new benchmark for turbine handling equipment efficiency.