Lifting equipment failures cause 60% of crane-related fatalities. Understanding proper inspection procedures for spreader bars and lifting beams protects workers and prevents catastrophic accidents. This guide provides step-by-step inspection protocols ensuring your equipment meets safety standards.

Spreader bars and lifting beams are critical below-the-hook devices converting crane loads into manageable forces for safe material handling. In 2021, a CDC study on lift zone safety found 60% of crane-related fatalities resulted from rigging failure in construction sites nationwide. According to Frank Riggs, Safety Director at Crane Inspection & Certification Bureau, 2023: “90% of lifting accidents trace back to inadequate pre-use inspections or human error in following established protocols.”

This comprehensive guide covers visual inspection criteria, regulatory compliance requirements, damage indicators requiring immediate equipment removal, documentation protocols, qualified inspector requirements, and practical techniques preventing accidents. For spreader bars, inspect two top lifting lugs, main body compression zones, and attachment points. For lifting beams, examine single top attachment point, bending stress areas, and multiple bottom lugs. Follow OSHA 1926.251 mandating pre-shift inspections, ASME B30.20 periodic inspection schedules, and maintain 125% proof-test certification. Document findings using standardized checklists, photograph deficiencies, and tag unsafe equipment immediately. When inspecting attachment hardware, verify shackle pin engagement, check sling angle compliance, and confirm load rating visibility.

Start daily inspections 15 minutes before first lift. For comprehensive inspection services and RFID lifecycle tracking, visit Tway Lifting first. Understanding these inspection fundamentals establishes foundation for examining specific equipment differences and regulatory requirements.

What Are Spreader Bars and Lifting Beams, and How Do They Differ?

Spreader bars and lifting beams are two distinct types of below-the-hook lifting devices that differ in design, load distribution, and structural mechanics. A spreader bar is a simple device consisting of a long bar that holds two slings apart, designed to convert lifting loads into pure compressive forces. These devices feature two lifting lugs on the top of the beam that attach to the legs of a chain or synthetic sling at a specific angle.

Spreader bars are typically smaller, lighter, and less expensive to design and manufacture than lifting beams of the same capacity. Some spreader bars can lift up to 200,000 lbs and can be built up to a length of 40 feet, making them suitable for heavy-duty applications.

In contrast, a lifting beam has a single attachment point centered on the top side of the beam for connecting to a crane, hoist, or other lifting machine. Lifting beams convert lifting loads into bending forces on the beam, requiring more rigid construction. They use more material and are heavier than spreader beams of equivalent capacity but require less overhead clearance compared to spreader bars, which need more headroom during operation.

The following sections will explore their specific applications and why proper identification is crucial for effective inspection procedures.

What Are the Typical Applications for Spreader Bars and Lifting Beams?

Spreader bars are ideal for lifting very wide or heavy-duty loads where weight is distributed evenly across the beam. There are several key applications where spreader bars excel, such as situations where load control is critical to prevent tipping, sliding, or bending. Spreader bars control crushing or damage to the load through sling angle control, making them essential for delicate or precisely balanced lifts.

Lifting beams serve different operational needs and are ideal for lighter and shorter span lifts. There are specific scenarios where lifting beams provide advantages, such as when overhead room is a concern or when handling loads that are too weak or flexible to be lifted without support, including long sheets of metal. Lifting beams are effective for handling out-of-balance loads and can control inward crushing forces while utilizing special load securement attachments for enhanced safety.

Why Is It Important to Distinguish Between Spreader Bars and Lifting Beams Before Inspection?

The distinction between spreader bars and lifting beams is crucial for proper inspection because these devices experience fundamentally different types of stress during operation. Spreader bars experience primarily compressive forces while lifting beams experience bending stress, requiring different inspection focal points and evaluation criteria.

The structural characteristics differ significantly, with spreader bars having two top lugs and lifting beams having a single top attachment point. There are distinct inspection focus areas that vary based on the type of stress each device experiences during operation, and the load-bearing mechanisms require different evaluation criteria during inspection to ensure safety and compliance with industry standards.

This understanding of structural differences and stress patterns directly influences the comprehensive inspection standards and regulations that govern these critical lifting devices.

What Standards and Regulations Govern Spreader Bar and Lifting Beam Inspections?

Standards and regulations for spreader bar and lifting beam inspections are governed by OSHA and ASME requirements that mandate specific inspection frequencies and proof testing protocols. These regulations ensure lifting equipment meets safety standards before use and maintains operational integrity throughout its service life.

Which OSHA and ASME Standards Apply to Lifting Device Inspections?

OSHA and ASME standards establish comprehensive requirements for lifting device inspections, proof testing, and safety protocols. OSHA 1926.251(a)(4) requires special custom design grabs, hooks, clamps, and lifting accessories to undergo proof testing before initial use. OSHA 1926.251 mandates rigging equipment inspection prior to each shift and requires a 125% proof test for all lifting accessories, including spreader bars and lifting beams.

Key applicable standards include:

- ASME B30.20: Defines safety requirements for below-the-hook lifting devices, covering marking, inspection, construction, and operation protocols

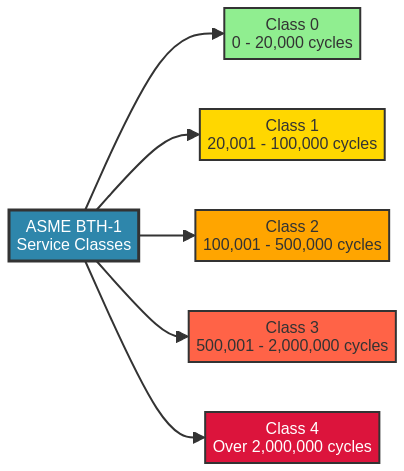

- ASME BTH-1: Specifies design calculations for various loading types and establishes design categories and service classes

- EN 13155: European harmonized standard specifying requirements for lifting beams and spreaders

How Frequently Should Spreader Bars and Lifting Beams Be Inspected According to Guidelines?

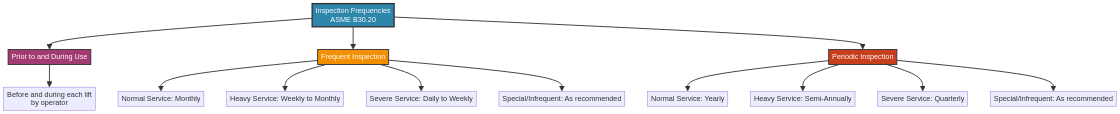

Inspection frequency follows a three-tier system based on usage patterns and regulatory requirements. OSHA mandates inspection prior to each shift and during use to ensure continuous safety compliance.

The inspection schedule includes:

- Prior to and During Use: Visual inspection by the operator before and during each lift

- Frequent Inspection: Visual examinations by operators or designated persons without required documentation

- Periodic Inspection: Thorough visual inspection by qualified personnel with mandatory record-keeping of external conditions

What Are the Legal Consequences of Failing to Inspect Lifting Equipment?

Failure to inspect lifting equipment results in serious legal and financial consequences including OSHA citations, workplace shutdowns, and potential criminal liability. Employers face fines ranging from $15,625 for serious violations to $156,259 for willful or repeated violations under current OSHA penalty structures.

Legal consequences include:

- Civil Penalties: OSHA fines for non-compliance with inspection requirements

- Criminal Liability: Potential charges for willful violations resulting in worker fatalities

- Work Stoppage Orders: Immediate cessation of operations until compliance is achieved

- Insurance Claims Denial: Workers’ compensation and liability coverage may be voided for non-compliant equipment

Following these inspection standards protects workers and ensures compliance with federal safety regulations. The next section details specific inspection procedures for spreader bars, including visual checks and component evaluation methods.

What Are the Steps to Properly Inspect Spreader Bars Before Use?

Proper spreader bar inspection follows systematic visual checks, structural assessment, hardware examination, and marking verification. OSHA 1926.251 mandates inspection prior to use on each shift, making this process critical for workplace safety. These inspections prevent equipment failures that contribute to crane-related incidents.

What Visual Checks Should Be Performed on Spreader Bars?

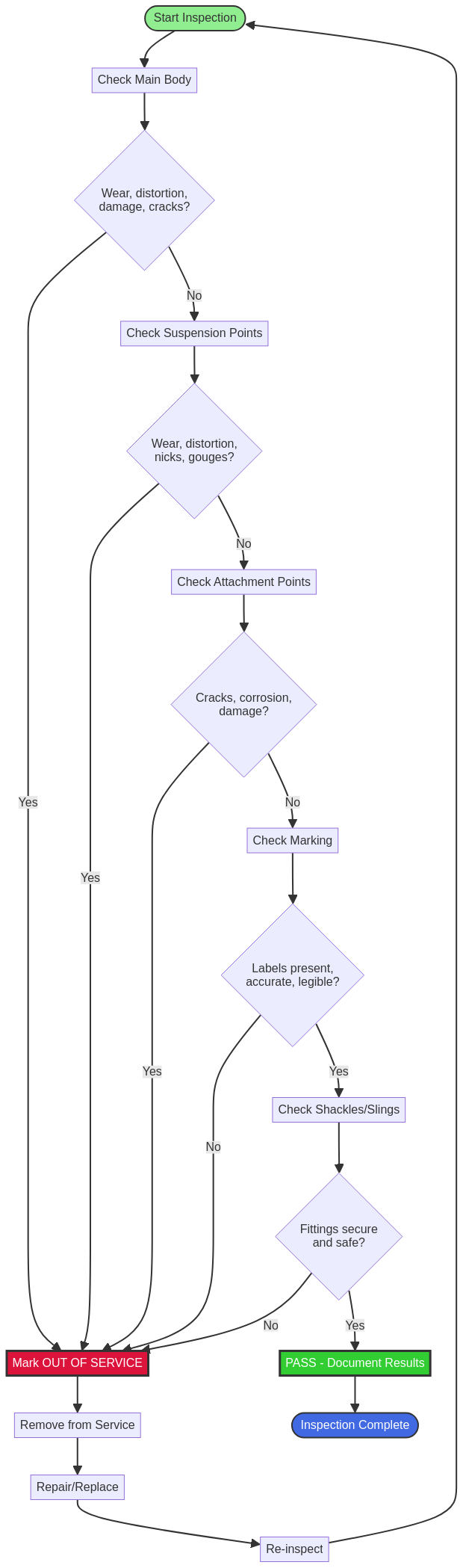

Visual checks on spreader bars focus on structural integrity assessment across all critical components. Inspect the main body for wear, distortion, damage, nicks, gouges, cracks, and corrosion that compromise load-bearing capacity. Examine suspension points and attachment points using identical criteria, as these areas experience concentrated stress during lifting operations.

Key visual inspection elements include:

- Main body structural assessment for visible defects

- Suspension point integrity verification

- Attachment point condition evaluation

- Manufacturer markings legibility confirmation

- Shackle and sling security assessment

Verify that manufacturer’s name, serial number, rated load, and required markings remain present, accurate, and legible for regulatory compliance.

How Can You Detect Bent, Cracked, or Deformed Components?

Bent, cracked, or deformed components indicate structural compromise requiring immediate equipment removal. Any crack, regardless of size, compromises structural integrity and creates failure risk during operation. Bending, twisting, or deformation signals overloading or damage that reduces load-bearing capacity.

Critical detection focuses include:

- Crack identification at stress concentration points

- Deformation assessment indicating overload history

- Wear pattern evaluation at connection interfaces

- Metal fatigue recognition requiring non-destructive testing

Excessive wear at connection points creates failure conditions, while metal fatigue may remain invisible externally, emphasizing the importance of professional testing methods.

What Should You Look for in Attachment Points, Shackles, and Hardware?

Attachment points, shackles, and hardware require thorough security and condition verification before each use. Check for excessive wear at connection points, which creates failure pathways during lifting operations. Inspect shackles for proper pin engagement and secure locking mechanisms that prevent accidental disengagement.

Hardware inspection priorities include:

- Fitting security and condition assessment

- Connection point wear evaluation

- Shackle pin engagement verification

- Load rating compliance confirmation

Ensure all hardware components maintain proper ratings for intended loads, as undersized components create catastrophic failure risks.

How Do You Check the Identification and Load Markings for Compliance?

Identification and load marking compliance verification ensures regulatory adherence and operational safety. Ensure all markings including manufacturer’s name, serial number, and rated load remain present and legible for proper equipment identification. Verify load ratings match intended lift requirements to prevent overloading incidents.

Compliance verification steps include:

- Marking presence and legibility confirmation

- Load rating requirement matching

- Certification date currency verification

- OSHA and ASME requirement compliance

Check that certification dates remain current with available documentation, and confirm all required OSHA and ASME marking requirements are met for legal operation. This documentation provides essential traceability for inspection history and regulatory compliance.

What Are the Steps to Properly Inspect Lifting Beams Before Use?

Lifting beam inspection follows a systematic approach focusing on bending stress points, attachment integrity, and documentation compliance. Proper inspection prevents equipment failure and ensures safe lifting operations.

What Signs of Damage or Wear Should Be Checked on Lifting Beams?

The signs of damage requiring immediate attention include cracks at stress concentration points, corrosion that weakens structural integrity, and deformation from overloading.

- Inspect for cracks at stress points where bending forces concentrate during lifting

- Check for rust and corrosion that reduce material strength and load capacity

- Look for permanent deformation or stretching indicating previous overloading

- Examine welds for cracks, poor penetration, or visible defects

Focus inspection efforts on areas experiencing maximum bending stress, as lifting beams convert loads into bending forces unlike spreader bars that handle compression.

How Do You Examine End Attachments, Slings, and Fittings?

End attachment examination ensures all connection points maintain structural integrity and proper engagement for safe load transfer.

- Verify end attachments are secure with no wear or damage at connection points

- Check slings for cuts, abrasions, or fraying that compromise tensile strength

- Inspect fittings for proper engagement and functioning safety latches

- Examine lifting lugs on the underside for wear, cracks, or deformation

Safety latches must operate smoothly and lock completely to prevent accidental disconnection during lifting operations.

What Role Does Documentation Play in Lifting Beam Inspections?

Documentation provides regulatory compliance, legal protection, and traceability for lifting beam maintenance history and certification status.

| Record Type | Required Information | Compliance Purpose |

| Periodic Inspections | Date, inspector signature, serial number | OSHA 1926.251 compliance |

| Maintenance Records | All repairs and modifications | Regulatory traceability |

| Proof Test Certificates | 125% WLL test results | ASME B30.20 requirements |

| Inspection History | Complete lifecycle tracking | Legal protection |

Detailed records demonstrate due diligence and support equipment reliability assessments for continued safe operation.

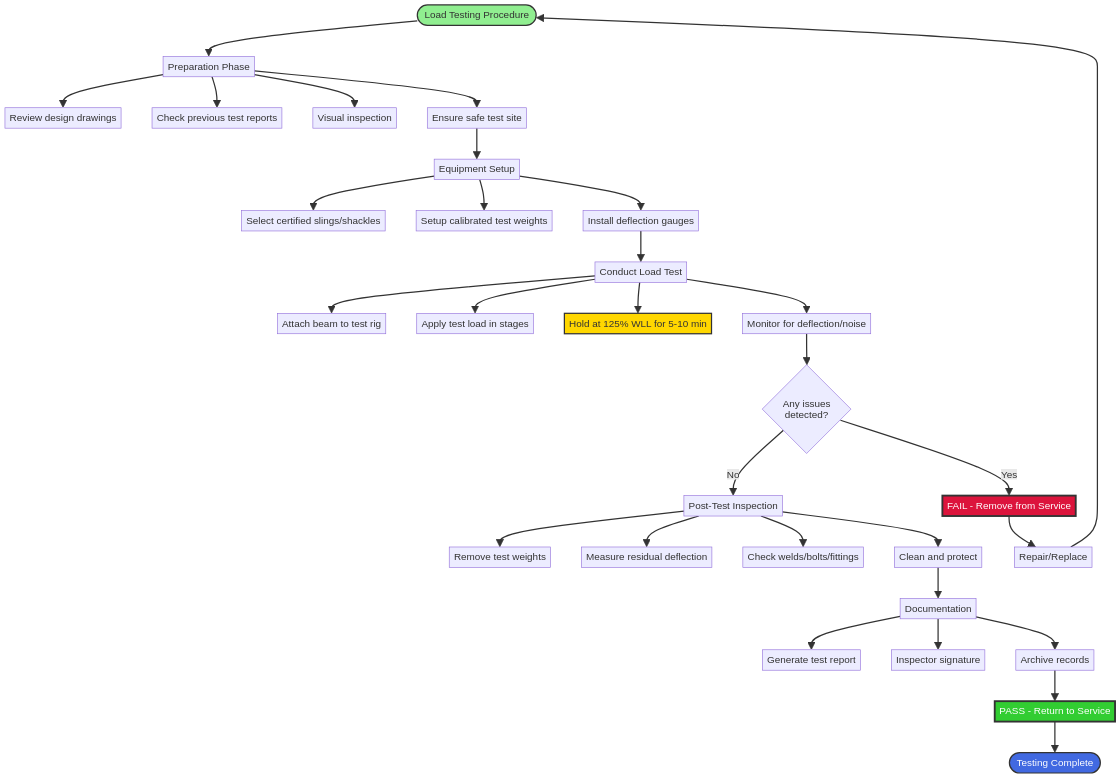

How Do You Verify Load Testing and Certification Records?

Load testing verification confirms lifting beams meet structural requirements and maintain certification for safe operation at rated capacities.

- Confirm proof load testing at 125% of working load limit completion

- Verify load test certificates contain current dates and proper documentation

- Check test reports include test date, applied load, duration, and results

- Ensure repairs or modifications have appropriate re-certification documentation

Current certification demonstrates equipment meets ASME B30.20 standards and OSHA requirements for lifting accessory safety. The next section examines common inspection problems and equipment removal criteria.

What Common Problems or Red Flags Should You Identify During Inspection?

Common problems during spreader bar and lifting beam inspections include corrosion damage, structural defects, and certification issues that compromise equipment safety. Identifying these red flags prevents catastrophic failures and ensures regulatory compliance.

What Types of Corrosion or Surface Damage Are Most Dangerous?

The most dangerous types of corrosion are deep pitting corrosion and surface cracks that compromise structural integrity. Deep pitting corrosion reduces the cross-sectional area of critical load-bearing components, while surface cracks can propagate under load and cause catastrophic failure. Rust and corrosion significantly weaken material strength, particularly at connection points and welds where stress concentrations occur.

| Entity | Attribute | Value |

| Deep pitting corrosion | Risk level | Most dangerous |

| Surface cracks | Propagation risk | High under load |

| Connection point corrosion | Failure risk | Highest |

| Weld corrosion | Structural risk | Critical |

Connection points and welds pose the highest risk when corroded because they experience maximum stress during lifting operations.

When Is Equipment Considered Unsafe for Use and Must Be Removed?

Equipment is unsafe for use when it shows any visible cracks, permanent deformation, or missing load markings. Any visible crack in the structure requires immediate removal from service, as cracks indicate material failure that will worsen under repeated loading. Permanent deformation, bending, or twisting indicates the equipment has been overloaded beyond its design limits.

Critical removal criteria include:

- Any structural cracks (immediate removal)

- Permanent deformation or bending

- Missing or illegible load markings

- Failed proof testing results

- Expired certification documents

Missing or illegible load markings make equipment unsafe because operators cannot verify weight capacity limits. Failed proof testing or expired certification legally requires removal from service under OSHA regulations.

What Should You Do If You Find Deficiencies During Inspection?

When deficiencies are found, immediately remove the equipment from service and tag it as unsafe to prevent accidental use. Report all findings to a competent or qualified person with authority to implement corrective measures, as required by OSHA standards.

Document all deficiencies in maintenance records, including the specific nature of damage, location, and inspector identification. This documentation provides legal protection and ensures proper tracking of equipment condition. Ensure that only qualified personnel complete all repairs before returning equipment to service, followed by appropriate re-certification testing.

The next section covers establishing thorough and effective inspection processes to prevent these common problems from occurring.

How Can You Ensure Your Inspection Process Is Thorough and Effective?

A thorough and effective inspection process combines structured documentation, qualified personnel, and comprehensive training programs. This systematic approach reduces equipment failures and creates safer lifting operations across all worksites.

What Inspection Checklists or Tools Should Be Used?

Inspection checklists provide systematic verification of all critical components and ensure consistency across different operators and sites. Effective checklists include visual inspection criteria, measurement tolerances, and clear pass/fail standards for each component.

Essential checklist elements include:

- Visual inspection points for cracks, corrosion, and deformation

- Hardware verification for shackles, pins, and attachment hardware

- Marking compliance for manufacturer labels and load ratings

- Documentation requirements with inspector signatures and dates

Digital inspection tools with photo capabilities improve record-keeping accuracy and enable real-time deficiency reporting. Mobile applications can integrate with asset management systems to track inspection history and maintenance schedules automatically.

Who Is Qualified to Perform Pre-Use Inspections?

Competent Person requirements define someone capable of identifying existing and predictable hazards with authority to take prompt corrective measures. Qualified Person standards require someone with recognized degree, certificate, or professional standing with extensive knowledge, training, and experience.

Operators must be trained and designated professionals to conduct pre-use inspections of basic visual elements. Only qualified persons should perform periodic inspections requiring detailed documentation and technical assessments.

Certification requirements vary by inspection type:

| Inspection Type | Required Qualification | Documentation Level |

| Pre-use visual | Competent Person | Basic checklist |

| Periodic detailed | Qualified Person | Formal reports |

| Post-repair | Qualified Person | Full certification |

How Can Training Improve Inspection Effectiveness and Safety?

Training effectiveness directly correlates with accident prevention in lifting operations. A 2019 study by the Crane Inspection & Certification Bureau found that 90% of crane accidents are caused by human error. The CDC reports that 60% of crane-related fatalities result from rigging failure.

Proper training helps personnel identify hazards that may not be immediately obvious to untrained operators. Regular training updates ensure inspectors stay current with latest standards and best practices from OSHA and ASME guidelines.

Training programs should include:

- Component identification for different lifting device types

- Failure mode recognition through case study analysis

- Documentation procedures for compliance requirements

- Emergency response for equipment failures

Effective training reduces human error through hands-on practice with actual equipment defects and standardized evaluation criteria. This systematic approach creates confident inspectors who can identify subtle problems before they become safety hazards, ensuring your next section covers how Tway Lifting supports these inspection processes through professional services and expertise.

What Are the Key Takeaways About Inspecting Spreader Bars and Lifting Beams Before Use?

The key takeaways for inspecting spreader bars and lifting beams center on systematic visual inspection, regulatory compliance, and immediate response to identified deficiencies. Operators must perform visual inspections before each shift and during use, checking for cracks, deformation, corrosion, and proper markings. Any visible crack or permanent deformation requires immediate equipment removal from service.

Critical inspection elements include:

- Visual examination of main body, suspension points, and attachment hardware for wear or damage

- Documentation verification ensuring proper markings, current certifications, and load test records

- Immediate removal of any equipment showing cracks, deformation, or missing markings

- Qualified personnel conducting periodic inspections with proper documentation

OSHA compliance requires proof testing at 125% of working load limit and maintaining detailed inspection records. With 90% of crane accidents caused by human error and 60% of crane-related fatalities from rigging failure, proper training and systematic inspection processes are essential for preventing workplace accidents and ensuring safe lifting operations.