When selecting critical lifting equipment for your industrial operations, understanding the proper applications and safety requirements can mean the difference between project success and catastrophic failure. Whether you’re overseeing construction sites, managing manufacturing facilities, or coordinating complex logistics operations, the right lifting beam or spreader bar configuration directly impacts both worker safety and operational efficiency. Your choice affects not only immediate project outcomes but also long-term compliance with stringent OSHA regulations and industry standards.

Lifting beams and spreader bars are engineered devices that enable safe overhead lifting of heavy, awkward, or delicate loads across diverse industrial applications. According to the U.S. Bureau of Labor Statistics, 2017: 297 crane-related fatalities occurred between 2011 and 2017, averaging 42 deaths annually. “Building a Wire Rope Products Plant in Indiana strengthened our position with the industrial sector in The Midwest… There are few plants in the country capable of producing lifting gear this heavy, the same day, and we are excited to be among the best,” states Peter Hansen, President & CEO of Tway Lifting Products, 2024.

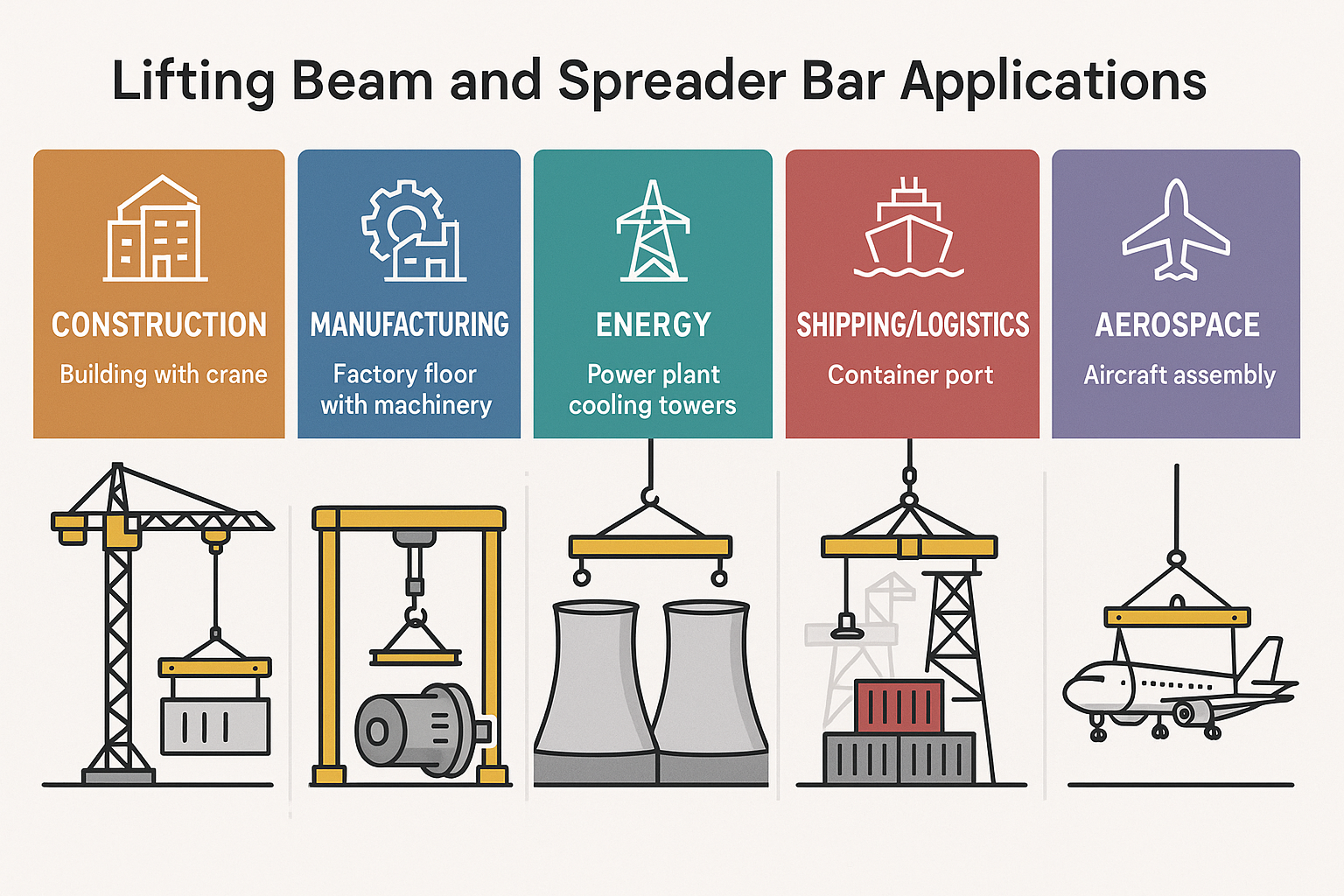

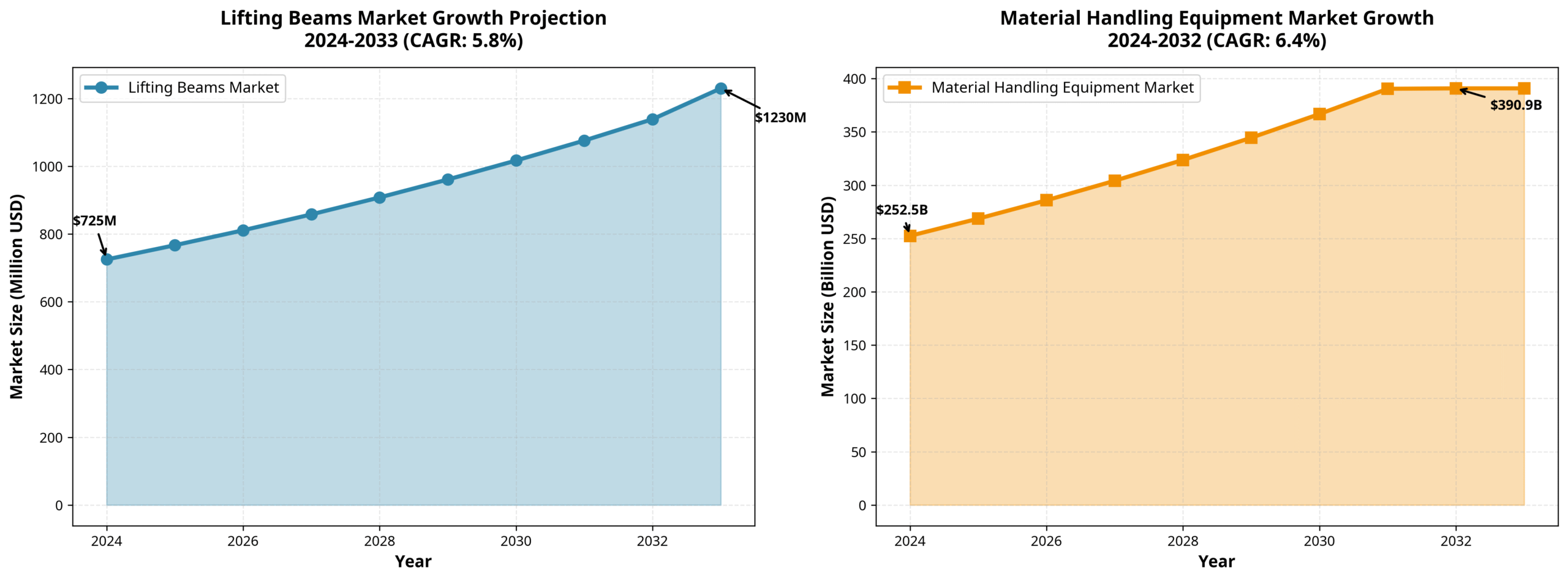

Construction applications utilize specialized lifting beams for bridge segments rated up to 100 tons, while manufacturing facilities employ modular spreader bars for production line material handling. The energy sector relies on nuclear-grade equipment for power plant construction, and shipping operations require container-specific spreader bars for efficient cargo handling. Aerospace applications demand precision four-point lifting systems, as demonstrated in NASA’s Flight Dynamics Research Facility project using Modulift equipment. The global lifting equipment market reached $84.52 billion in 2024, with the lifting beams segment valued at $725 million, reflecting growing demand across all sectors.

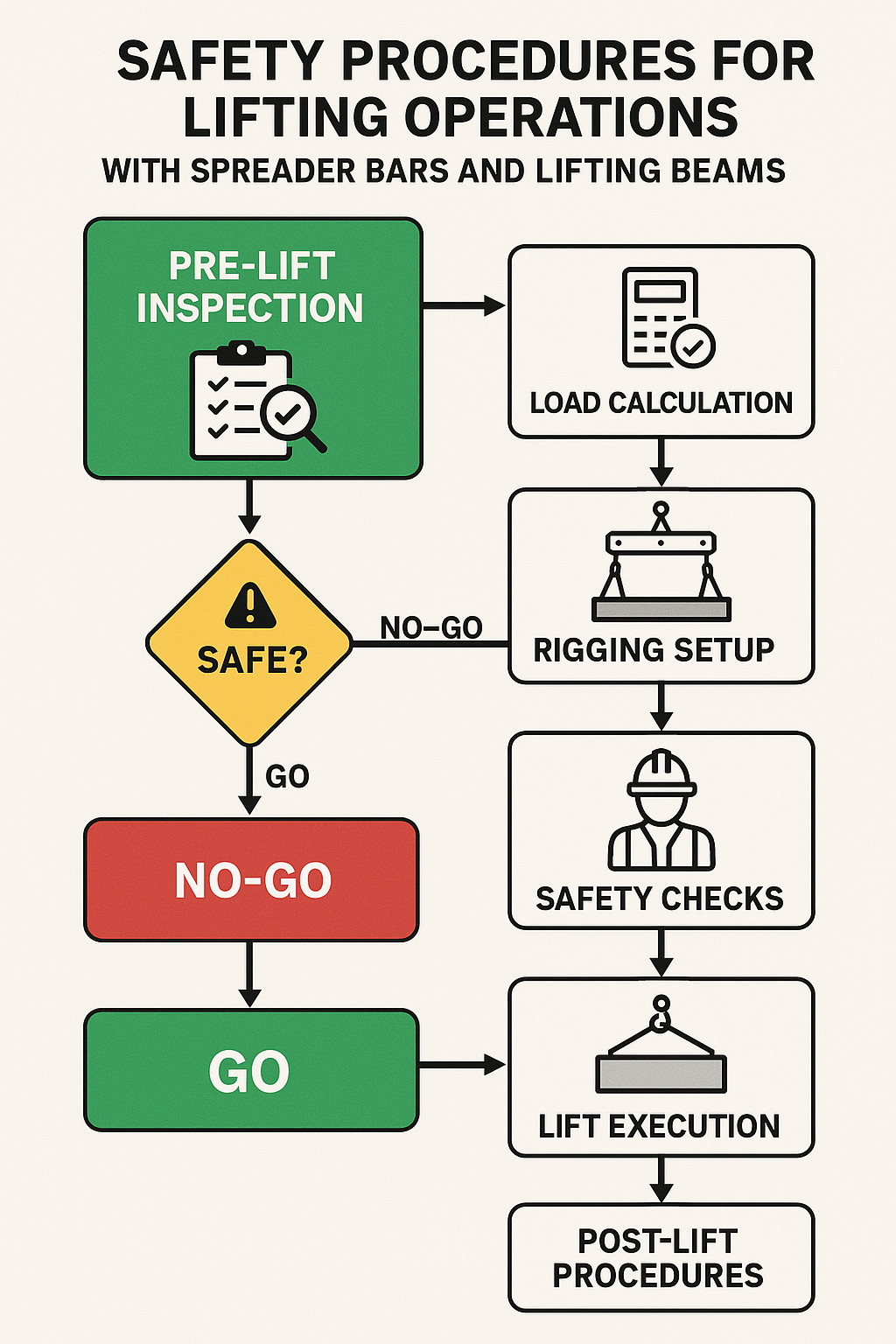

For immediate safety improvements, ensure all custom-designed lifting accessories undergo 125% proof-testing before use, as mandated by OSHA regulations. Consider implementing modular systems that allow quick reconfiguration for varying load dimensions while maintaining structural integrity.

This comprehensive analysis examines how different industries leverage these critical lifting devices, exploring sector-specific requirements, safety protocols, and emerging technologies that enhance operational efficiency while minimizing workplace hazards.

How Do Lifting Beams and Spreader Bars Work in the Construction Industry?

Lifting beams and spreader bars work in the construction industry by distributing loads safely across multiple lifting points, preventing structural damage and reducing workplace fatalities. Construction-related crane deaths account for a significant share of 5,283 total workplace fatalities in 2023, with an average of 42 to 44 crane-related deaths occurring annually in the United States. These specialized lifting devices enable safe installation of ironwork using mobile cranes, bridge segment lifting, steel component handling, and infrastructure development projects. Heavy-duty lifting beam rentals rated up to 100 tons provide essential support for bridge segments, machinery, and steel components.

The following sections examine the specific load types handled in construction, critical safety considerations, and regulatory requirements that govern lifting equipment use.

What Types of Loads Are Commonly Handled in Construction?

The types of loads commonly handled in construction include bridge segments, steel components, flexible materials, and heavy machinery requiring specialized lifting solutions. Bridge segments require specialized lifting beams rated up to 100 tons to manage their substantial weight and dimensions safely. Steel components and ironwork installations use mobile cranes with appropriate lifting attachments to ensure precise positioning and worker safety.

Construction projects frequently handle long or thin sheets of metal or steel plates that are too weak or flexible to be lifted without proper support systems. Heavy machinery and equipment for infrastructure development projects demand robust lifting beam configurations to distribute weight evenly and prevent structural failure during transportation and installation.

What Are the Safety Considerations for Construction Applications?

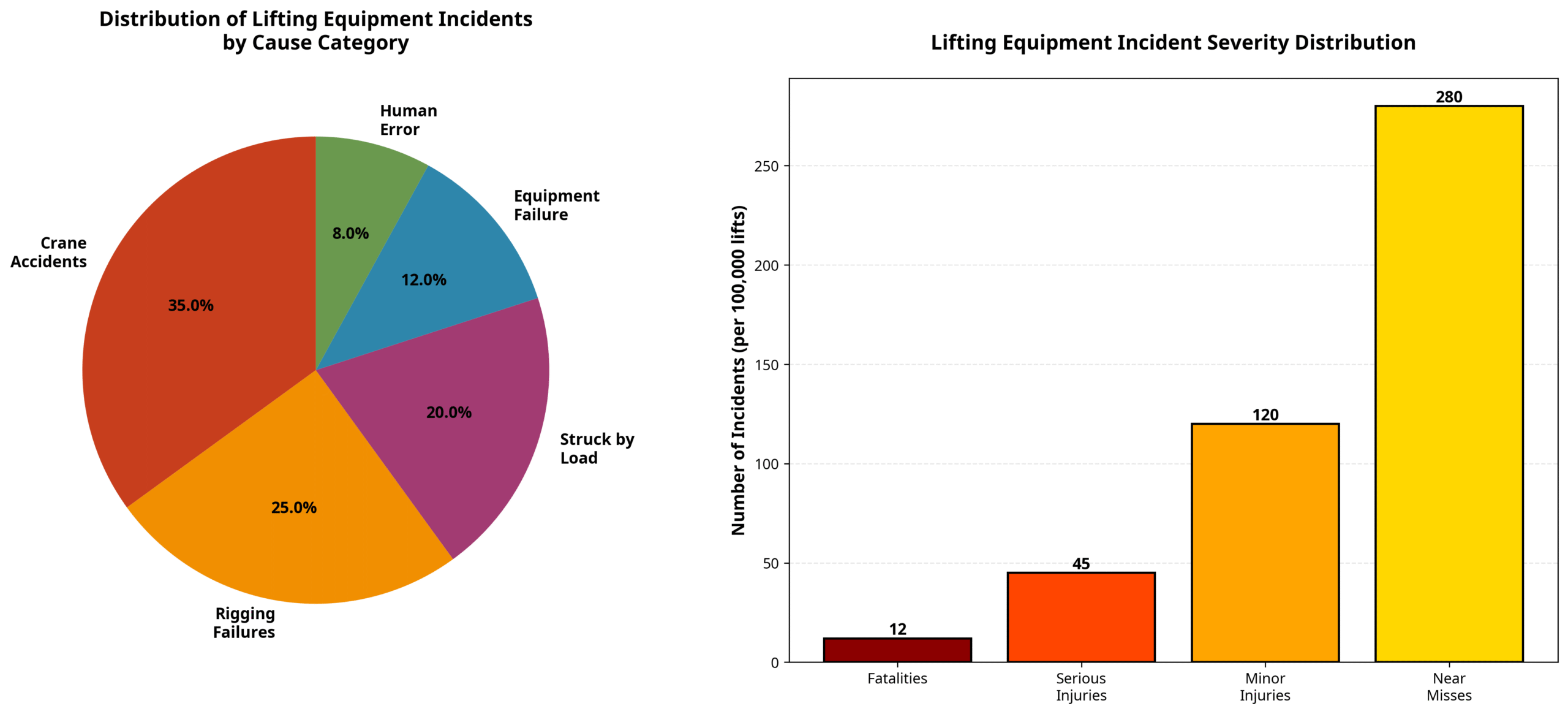

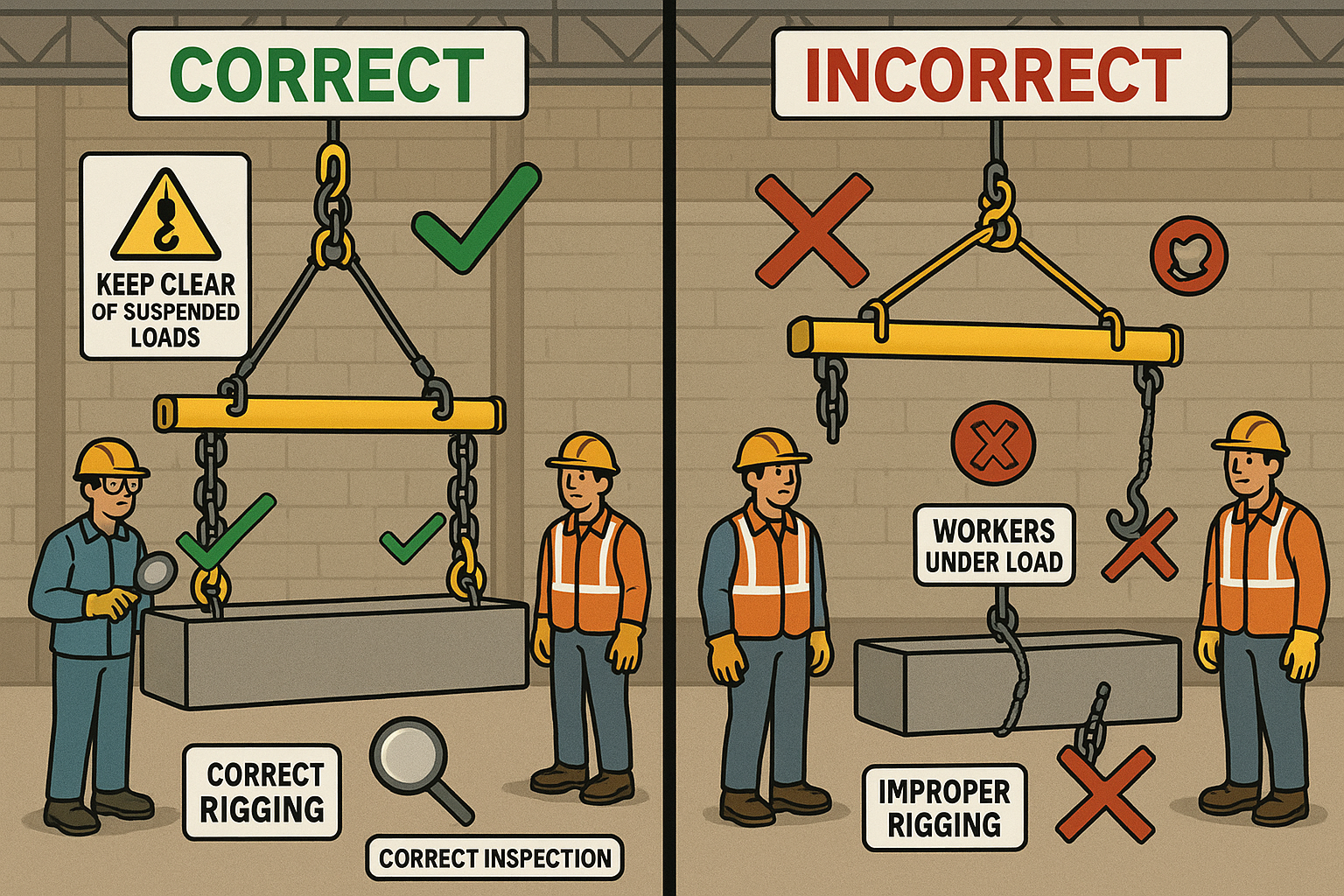

The safety considerations for construction applications center on preventing human error and implementing proper rigging protocols to reduce the 297 crane-related fatalities that occurred between 2011 and 2017. According to the U.S. Bureau of Labor Statistics, this represents an average of 42 deaths per year in construction crane operations. Approximately 90% of crane accidents result from human error, including improper communication, poor load planning, and misjudged movement paths.

A comprehensive review of 249 overhead crane incidents revealed 838 OSHA violations resulting in 133 injuries and 133 fatalities. Major incident causes include:

- Workers crushed by loads

- Dropped loads from rigging failure

- Falls from height during lifting operations

- Workers struck by crane components

Proper training and adherence to safety protocols significantly reduce these risks by ensuring operators understand load dynamics and maintain clear communication throughout lifting operations.

How Do Regulations Impact Lifting Equipment Use in Construction?

Regulations impact lifting equipment use in construction through mandatory testing, certification, and design standards that ensure worker safety and equipment reliability. OSHA requires custom-designed lifting accessories be proof-tested to 125% of rated load before use per 29 CFR standards, establishing baseline safety margins for all specialized equipment.

All crane operators in construction must be nationally certified starting November 10, 2018 and re-tested every 5 years to maintain current competency levels. ASME B30.20-2026 sets comprehensive standards for below-the-hook lifting devices covering construction, inspection, testing, operator training, and maintenance requirements.

| Regulation | Requirement | Purpose |

| OSHA 29 CFR | 125% proof-testing of custom devices | Verify load capacity before use |

| National Certification | Operator certification every 5 years | Maintain operator competency |

| ASME B30.20-2026 | Device standards and maintenance | Ensure equipment reliability |

All devices must display marked rated load capacity, identification tags with manufacturer information, and serial numbers with designs completed under qualified engineering supervision. These regulatory requirements create a comprehensive safety framework that protects construction workers while maintaining operational efficiency across diverse project types.

How Are Lifting Beams and Spreader Bars Utilized in Manufacturing?

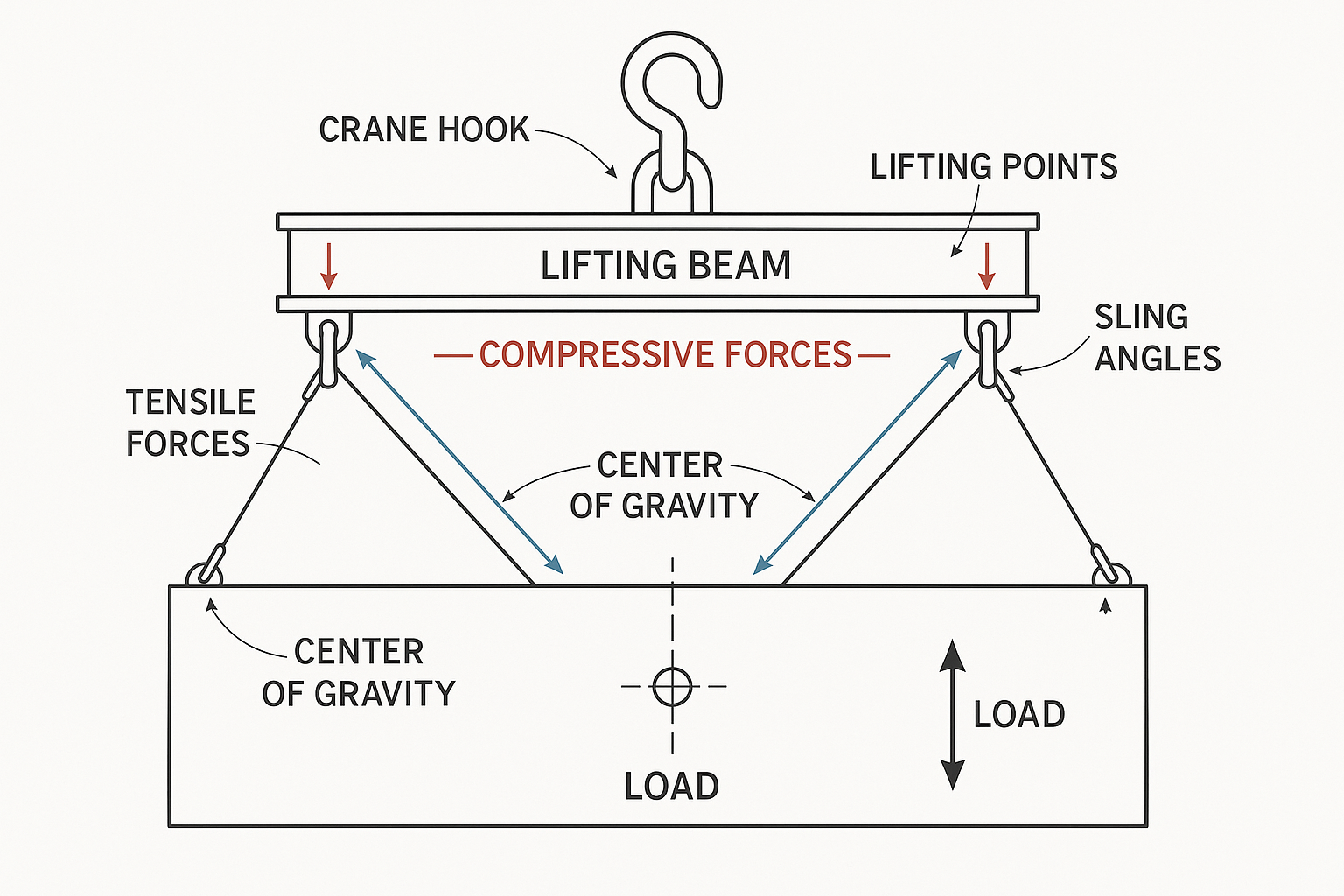

Lifting beams and spreader bars are utilized in manufacturing for machinery handling, heavy industrial loads, and production line material handling within an Industrial Lifting Equipment Market valued at $71.79 billion in 2024. Lifting beams provide multiple lifting points underneath loads and handle out-of-balance loads using variable or fixed lifting lugs. These devices serve manufacturing facilities by distributing weight safely across multiple attachment points while maintaining precise load control essential for production environments.

Manufacturing operations rely on these lifting solutions for three primary applications: production line material handling requiring precise load control, heavy machinery installation and maintenance operations, and movement of rough castings or irregularly shaped metal parts using wire rope slings. The following sections examine specific manufacturing processes, material handling challenges, and customization benefits that make these devices indispensable in modern manufacturing facilities.

Which Manufacturing Processes Rely on These Lifting Devices?

Manufacturing processes that rely on these lifting devices include production line material handling requiring precise load control, heavy machinery installation and maintenance operations, and movement of rough castings or irregular shaped metal parts. Production lines depend on lifting beams for controlled movement of components between workstations without damage. Heavy machinery installation involves spreader bars to distribute weight evenly during equipment positioning and alignment.

Metal fabrication processes utilize these devices for handling rough castings, heavy forgings, and irregularly shaped components that require multiple lifting points. Wire rope slings work with lifting beams to secure hot metal parts during manufacturing processes. Maintenance operations employ adjustable spreader bars for equipment removal and replacement in confined production spaces.

What Material Handling Challenges Exist in Manufacturing Facilities?

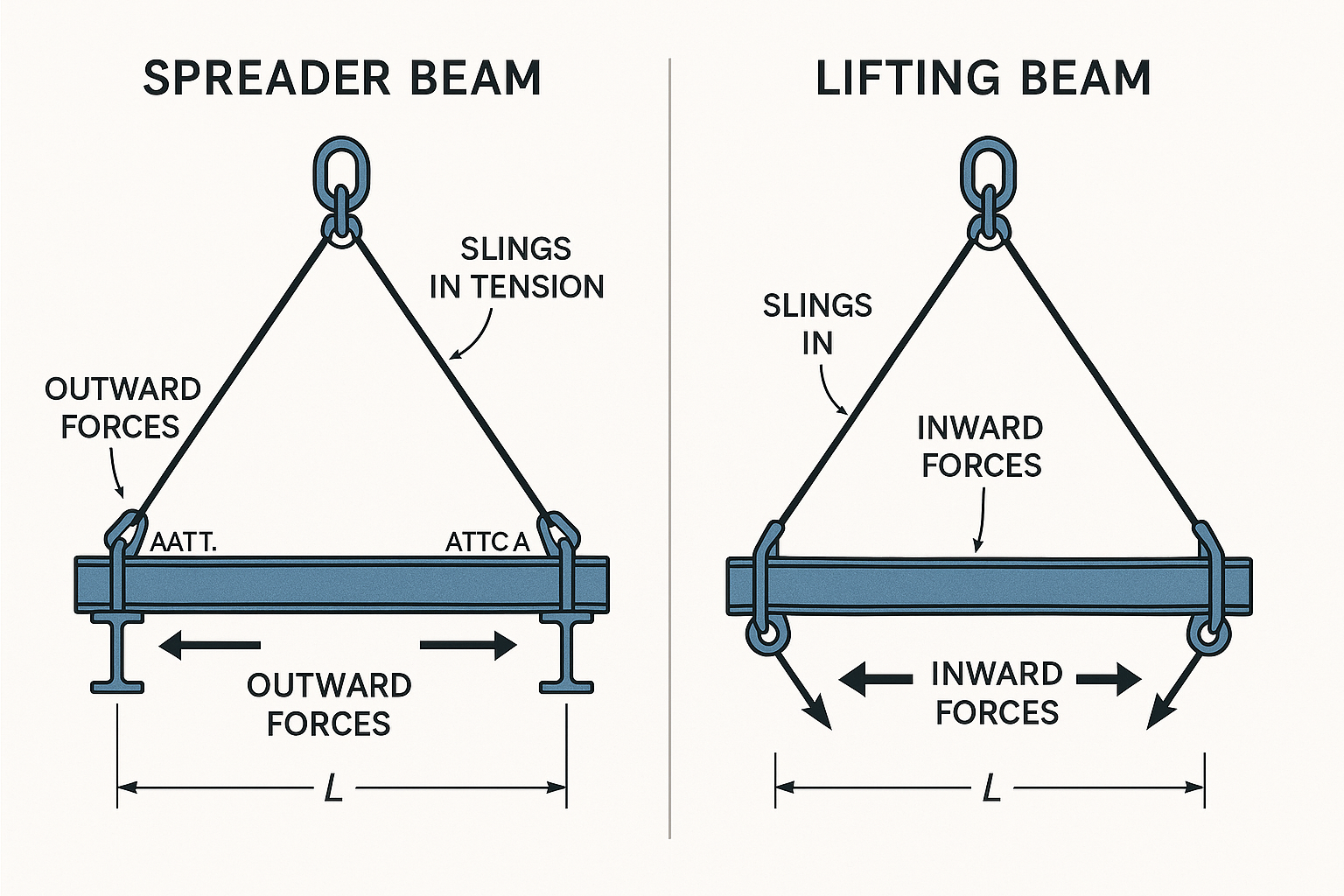

Material handling challenges in manufacturing facilities include limited headroom situations where spreader beams requiring more overhead space are not ideal, need for flexibility to handle loads of varying dimensions, and requirement to control inward crushing forces for delicate components. Limited ceiling height restricts spreader beam use since these devices require additional vertical clearance above the load.

Manufacturing facilities face challenges with:

- Variable load dimensions requiring adjustable or modular spreader bar configurations

- Delicate components needing special load securement attachments to prevent crushing damage

- Space constraints limiting equipment maneuverability in production areas

- Weight distribution requirements for irregularly shaped manufacturing components

Facilities address these challenges through lifting beam selection that provides low-profile lifting solutions and customizable attachment configurations for diverse manufacturing loads.

How Does Customization Benefit Manufacturing Operations?

Customization benefits manufacturing operations by matching configuration to installation’s unique environment for maximum operational productivity and efficiency, with nearly every overhead lifting solution incorporating customization to match specific application needs. Modular spreader bars can be assembled in different configurations to fit different types of loads with parts that can be repaired or replaced in isolation.

Customization advantages include:

- Adjustable spreader bars allowing adaptation to various load dimensions through telescopic systems

- Variable attachment points accommodating different component sizes and shapes

- Specialized load securement attachments designed for specific manufacturing processes

- Modular designs enabling component replacement without complete system replacement

Manufacturing operations achieve optimal efficiency when lifting equipment matches their specific production requirements, reducing downtime and improving safety through purpose-built solutions.

This examination of manufacturing applications demonstrates how lifting beams and spreader bars address industry-specific challenges through customizable solutions, setting the foundation for understanding their critical role in energy sector applications.

What Role Do Lifting Beams and Spreader Bars Play in the Energy Sector?

Lifting beams and spreader bars play critical roles in energy sector operations, handling massive components in nuclear power construction, oil and gas installations, and renewable energy projects. The Heavy Lifting Equipment Market exceeded $25 billion in 2024 and is expected to grow at a CAGR of 5.8% from 2025 to 2034, driven by expanding energy infrastructure needs.

Nuclear power plant construction projects like Hinkley Point utilize Modulift spreader beams for precise handling of reactor components. Manual chain hoists and specialized lifting solutions enable safe installation of turbines, generators, and modular construction elements. Energy sector applications require extreme precision due to the critical nature of components and strict safety protocols.

The following sections examine specific transport challenges, environmental requirements, and compliance standards that define lifting equipment use in energy applications.

How Are Heavy Components Moved in Oil, Gas, and Renewable Energy Projects?

Heavy components in energy projects are moved using specialized lifting beams designed for nuclear power facilities and extreme-weight applications. Equipment must handle weights ranging from 5 to 100 tons with configurable spans from 4 to 40 feet to accommodate diverse component sizes.

Modulift spreader beams have proven integral to major energy infrastructure projects like Hinkley Point nuclear construction, where precision and reliability are non-negotiable. Nuclear reactor vessels, steam generators, and turbine assemblies require multi-point lifting configurations to distribute loads safely across multiple attachment points.

Offshore wind installations use specialized spreader bars for nacelle and blade handling, while oil and gas projects employ heavy-duty lifting beams for drilling equipment and pipeline sections.

What Environmental Factors Affect Equipment Selection in the Energy Industry?

Environmental factors significantly impact equipment selection, with long-term durability and corrosion resistance particularly critical for energy sector applications. Equipment must withstand harsh conditions in offshore oil and gas operations, including saltwater exposure, extreme temperatures, and high winds.

Stainless steel chain slings and specialized coatings are required for corrosion resistance in marine environments. Nuclear facilities demand materials that resist radiation exposure while maintaining structural integrity over decades of service.

Renewable energy projects face unique challenges, with wind farm installations requiring equipment that performs reliably in coastal salt spray and desert installations needing protection against sand abrasion and UV degradation.

What Are Common Compliance Standards in Energy Applications?

Common compliance standards in energy applications center on ASME BTH-1, which designates design criteria for below-the-hook lifting devices and provides minimum structural, mechanical, and electrical design criteria. Equipment must meet strict nuclear industry standards when used in power plant construction, including radiation-resistant materials and enhanced documentation requirements.

Proof-testing to 125% of rated load is required per OSHA standards for custom-designed lifting accessories. Nuclear facilities often require additional testing protocols and certified material traceability for all lifting components.

Energy sector compliance extends beyond basic safety standards to include environmental impact assessments and long-term performance validation, ensuring equipment maintains reliability throughout extended service life in critical infrastructure applications.

How Are Lifting Beams and Spreader Bars Applied Within Shipping and Logistics?

Lifting beams and spreader bars are essential equipment in shipping and logistics operations for handling containers, heavy cargo, and ensuring safe load distribution during transportation processes. The Fixed Spreader Beam Market reached $1.5 billion in 2024 and is projected to grow to $2.8 billion by 2033, reflecting the critical importance of these devices in global supply chain operations.

Container handling represents the primary application, with specialized container spreader bars equipped with slings and lugs providing secure attachment and safe release mechanisms. These devices distribute weight evenly across the beam, eliminating stress concentration on single lifting points that could compromise cargo integrity or worker safety. However, the industry faces significant safety challenges, as documented in an OSHA case study where a fatal incident involving a 2,500-pound I-beam spreader bar killed two workers in a longshoring operation.

The following sections detail specific cargo types requiring specialized lifting solutions, efficiency benefits during loading operations, and critical safety risks that must be managed in logistics environments.

What Types of Cargo Require Specialized Lifting Solutions?

The types of cargo requiring specialized lifting solutions include standardized shipping containers, bulk materials, and oversized loads that exceed standard handling capabilities. Container spreader bars are specifically designed for standardized shipping containers, providing secure connection points that match international container specifications for consistent handling across global ports and terminals.

Bulk cargo presents unique challenges, such as grain bags totaling 17,636 pounds that require specialized spreader bar configurations as documented in OSHA incident reports. Wide or heavy-duty loads require spreader beams to distribute weight evenly across the beam structure, preventing load deformation and ensuring safe transport of cargo that exceeds standard container dimensions or weight limits.

How Do Spreader Bars Contribute to Efficient Loading and Unloading?

Spreader bars contribute to efficient loading and unloading by controlling loads and reducing chances of load tipping, sliding, bending, crushing, or damage during transfer operations. Container spreader bars equipped with specialized attachments enable secure connection and safe release of containers, streamlining port operations and reducing handling time per container.

The weight distribution function eliminates stress on single lifting points, allowing operators to handle heavier loads safely while maintaining cargo integrity. This even load distribution across the beam structure enables faster cycle times and reduces the risk of cargo damage that could delay shipments or require costly repairs.

What Are the Key Risks in Logistics Lifting Operations?

The key risks in logistics lifting operations include equipment failure, rigging issues, and unsafe worker positioning that can result in fatal accidents. A documented fatal incident involved a 15-ton bridge crane with a 2,500-pound spreader bar that fell and killed two longshoremen due to severed wire rope and lack of proper inspections, highlighting the critical importance of equipment maintenance.

According to the Centers for Disease Control, 60% of crane-related fatalities stem from rigging issues, making proper rigging procedures essential for worker safety. Workers positioned beneath suspended loads represent a major safety violation identified in longshoring fatality cases, emphasizing the need for strict adherence to safe work zone protocols during lifting operations.

This section demonstrates how lifting beams and spreader bars serve as fundamental equipment in shipping and logistics while requiring careful attention to safety protocols and equipment maintenance to prevent tragic accidents in port and warehouse environments.

In What Ways Do Lifting Beams and Spreader Bars Support Aerospace and Aviation?

Lifting beams and spreader bars support aerospace and aviation through precision handling of aircraft components, specialized tooling applications, and critical infrastructure installation. NASA’s Flight Dynamics Research Facility utilized two Modulift MOD 50 spreader beams to create a 4-point lift for their 120-foot vertical wind tunnel. These applications require synthetic web and round slings to protect machined aerospace components during movement. The following sections detail how precision handling, certifications, and failure consequences shape aerospace lifting requirements.

How Is Precision Handling Achieved for Delicate Aerospace Components?

Precision handling for delicate aerospace components is achieved through four-point lifting configurations using specialized spreader beams that ensure balanced load distribution. Synthetic sling products provide surface protection for machined aerospace components during movement, preventing damage to critical surfaces. Rigid and heavy-duty lifting beam designs prove ideal for components too weak or flexible to be lifted without support, maintaining structural integrity throughout the lifting process.

What Certifications or Standards Apply in Aerospace Uses?

The certifications and standards that apply in aerospace uses include ISO-9001 certified precision manufacturing required for all aerospace lifting applications. Industries like aerospace require only the best quality certifications for chain slings and lifting equipment due to mission-critical nature of operations. Equipment used in NASA projects must meet stringent government aerospace standards that exceed typical commercial requirements.

What Are the Consequences of Lifting Equipment Failure in Aviation?

The consequences of lifting equipment failure in aviation include potential delays to critical space exploration missions and compromised facility capabilities. NASA Director Clayton Turner stated facility work will “literally change the world,” highlighting the critical nature of proper lifting equipment. Failure during installation of the 120-foot vertical wind tunnel at NASA’s facility could have delayed exploration missions to Moon, Mars, Venus and Titan. The new NASA facility has significantly greater capability while greatly reducing maintenance and operating costs compared to 1930s-era equipment, making proper installation essential for space exploration advancement.

This aerospace focus demonstrates how specialized lifting equipment enables breakthrough scientific research and space exploration capabilities for the next generation.

How Do Lifting Beams and Spreader Bars Enhance Safety and Efficiency Across Industries?

Lifting beams and spreader bars enhance safety and efficiency by providing controlled load distribution, reducing workplace accidents, and optimizing operational productivity across multiple industries. The global Lifting Beams Market reached $725 million in 2024, projected to expand at a 5.8% CAGR to reach $1.23 billion by 2033, driven by smart technology integration including IoT sensors, load monitoring systems, and automated controls.

What Safety Advantages Do These Devices Offer?

Safety advantages include optimal load control through perpendicular sling positioning, balanced weight distribution, and reduced load instability risks. Spreader beams and lifting beams maintain lifting slings at or near a 90° angle perpendicular to the horizon for optimal load control. Multiple attachment points transform the physics of lifting action, providing better balance for long and thin loads. The equipment helps control loads and reduces chances of load tipping, sliding, bending, crushing, or damage during lifting operations.

How Can They Improve Workplace Productivity?

Workplace productivity improves through reduced operational costs, enhanced equipment versatility, and minimized maintenance downtime. Initial investment in automation and mechanization pays off through increased productivity and reduced operational costs over time. The ability to quickly reconfigure spreader bars improves operational efficiency and reduces the need for multiple specialized tools. Overhead lifting solutions provide reliable service often for decades with far fewer wear and service points compared to floor-based transport, requiring less frequent maintenance than other types of load transport equipment and minimizing both planned and unplanned downtime.

What Training Is Necessary for Proper Use?

Proper use requires OSHA-compliant certification programs covering crane operation and rigging standards. The NCCCO program is the only program recognized by federal OSHA as meeting both OSHA and ASME requirements for crane operator certification. Rigger training covers OSHA standards 29 CFR 1926.180 and 29 CFR 1926.1400 plus ASME B30.5 standards. Typical certification requires a 7-hour on-site course with classroom instruction, practical instruction, and testing valid for 3 years.

This foundation of enhanced safety protocols, productivity improvements, and comprehensive training requirements demonstrates how lifting beams and spreader bars serve as critical equipment investments across industries, setting the stage for understanding proper equipment selection methodologies.

How Should You Approach Selecting Lifting Beams and Spreader Bars for Your Industry?

Selecting lifting beams and spreader bars requires understanding your specific industry needs within a rapidly expanding global market. The Global Lifting Equipment Market reached $84.52 billion in 2024 and projects growth to $88.33 billion in 2025, driven by rapid industrialization across Asia Pacific regions including China, India, and Japan. Spreader beams offer superior material efficiency—typically smaller, lighter, and less expensive than lifting beams while maintaining comparable load capacities.

Your selection process should prioritize load specifications, environmental conditions, and regulatory compliance specific to your industry sector. Different industries demand distinct approaches: construction requires heavy-duty solutions for bridge segments and steel components, manufacturing needs customizable systems for production lines, energy sectors demand corrosion-resistant equipment for harsh environments, shipping operations require specialized container handling capabilities, and aerospace applications need precision instruments meeting stringent certifications.

Can You Rent Spreader Bars for Your Next Project?

Yes, you can rent Spreader Bar equipment for your next industrial lifting project to ensure compliance, safety, and efficiency. Renting spreader bars allows you to access high-capacity, proof-tested lifting systems without large upfront investments—ideal for construction, energy, and manufacturing operations. Tway Lifting provides comprehensive lifting solutions backed by 79 years of American manufacturing excellence since 1945. The company operates as America’s premier source for quality lifting products with ISO-9001 certified precision manufacturing standards. Tway Lifting offers Fixed and Adjustable Spreader Bars with capacities ranging from 5 to 100 tons and configurable spans from 4 to 40 feet, accommodating diverse industrial applications.

The company maintains two Rigging Equipment Superstores in Indianapolis and Fort Wayne, Indiana, featuring an on-site Wire Rope Products Plant capable of producing heavy lifting gear the same day orders are placed. President and CEO Peter Hansen states: “There are few plants in the country capable of producing lifting gear this heavy, the same day, and we are excited to be among the best.” Free delivery and pickup services extend nationwide for spreader bar and lifting beam rentals, ensuring accessibility across all U.S. markets.

What Are the Key Takeaways About Lifting Beam and Spreader Bar Applications by Industry We Covered?

Industry-specific applications reveal distinct safety profiles and market dynamics across sectors. The construction industry faces an average of 42-44 crane-related deaths annually, with 90% of accidents caused by human error, emphasizing the critical importance of proper equipment selection and operator training. Manufacturing sectors benefit from customizable solutions within the $71.79 billion Industrial Lifting Equipment Market in 2024, enabling optimized production line operations.

Energy sector applications include nuclear power construction projects utilizing specialized systems, contributing to the Heavy Lifting Equipment Market exceeding $25 billion in 2024. Shipping and logistics operations utilize container spreader bars within the $1.5 billion Fixed Spreader Beam Market, projected to reach $2.8 billion by 2033. Aerospace applications require precision handling exemplified by NASA’s use of Modulift systems for critical space exploration facility construction. Smart technology integration including IoT sensors and automated controls drives overall market growth at 5.8% CAGR through 2033, transforming traditional lifting operations across all industries.