If you’re responsible for lifting equipment in your facility, you know that compliance audits can be daunting. Whether you’re facing your first OSHA inspection or preparing for a routine audit, we understand the pressure to ensure every crane, hoist, and rigging component meets strict safety standards. You’re in the right place—this comprehensive guide will walk you through exactly how to prepare for and pass your lifting equipment compliance audit with confidence.

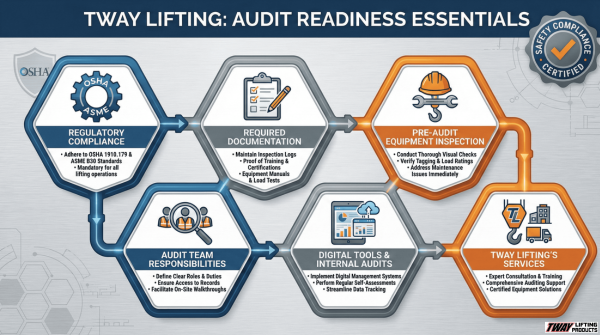

Preparing for a lifting equipment compliance audit is a systematic process that involves understanding regulatory requirements, organizing comprehensive documentation, conducting thorough equipment inspections, and establishing ongoing compliance protocols to ensure your facility meets OSHA and ASME standards while protecting your workforce from the average 42-44 annual crane-related fatalities in the United States.

TL;DR Summary:

• Key regulatory requirements include OSHA regulations (29 CFR 1910.179 and 1910.180) and ASME B30 series standards, with inspections required daily, monthly, and annually, carrying penalties up to $165,514 per violation for non-compliance.

• Essential documentation encompasses detailed maintenance logs, third-party inspection certificates, load testing reports, operator certifications, and equipment inventories with manufacturer specifications readily accessible for review.

• Pre-audit equipment assessment focuses on identifying common issues like hook wear, structural integrity problems, and hoisting rope degradation while implementing preventive maintenance programs to address deficiencies.

• Successful audit preparation involves safety officers ensuring proper training qualifications and maintenance staff implementing rigorous inspection schedules, with management fostering a strong safety culture throughout the organization.

• Long-term compliance relies on digital transformation tools including inspection software (projected $870 million market by 2031), IoT monitoring devices, and periodic internal audits for continuous improvement.

• Tway Lifting provides expert industrial rigging inspection services designed to identify potential hazards and help organizations achieve compliance with all applicable OSHA and ASME standards.

Quick Tip: Schedule a mock audit 30-60 days before your official compliance audit date—this gives you sufficient time to address any deficiencies discovered while maintaining momentum in your preparation efforts.

What Are the Key Regulatory Requirements for Lifting Equipment Compliance Audits?

Key regulatory requirements for lifting equipment compliance audits are established by OSHA and ASME standards that govern inspection frequencies, documentation standards, and safety protocols. These requirements form the foundation for workplace safety and legal compliance across all lifting operations.

Which US Laws and Standards Govern Lifting Equipment Inspections?

US laws and standards governing lifting equipment inspections are primarily established through OSHA regulations and ASME technical standards. OSHA regulations for lifting equipment are found in Title 29 of the Code of Federal Regulations (CFR), with 29 CFR 1910.179 covering overhead, gantry, and wall cranes for inspections, maintenance, and operation requirements. 29 CFR 1910.180 details requirements for mobile cranes including crawler, locomotive, and truck-mounted cranes.

The ASME B30 series provides detailed technical and safety requirements for lifting and rigging equipment across 29 volumes. Key standards include:

- ASME B30.2 covers design, installation, inspection, testing, and maintenance of overhead cranes

- ASME B30.5 addresses mobile crane requirements including stability, load charts, and operation

- ASME B30.9 specifies inspection, removal criteria, and safe use of various sling types

- ASME B30.20 establishes safety requirements for below-the-hook lifting devices including lifters and magnets

ASME standards are incorporated by reference into OSHA regulations, making compliance with these technical standards legally mandatory for all lifting operations.

How Frequently Are Compliance Audits Required for Lifting Equipment?

Compliance audits for lifting equipment are required at multiple intervals including daily, monthly, and annual inspections, plus special inspections after modifications or repairs. 29 CFR 1910.179 requires frequent and periodic inspections of critical components such as hoisting ropes and brakes. Monthly rope inspections must be documented in maintenance logs to demonstrate ongoing compliance with regulatory standards.

What Are the Consequences of Non-Compliance During an Audit?

The consequences of non-compliance during an audit include substantial financial penalties, legal liability, and operational disruptions. An average of 42-44 crane-related fatalities occur each year in the United States, highlighting the critical importance of compliance. A review of 249 overhead crane incidents revealed 838 OSHA violations, leading to 133 injuries and 133 fatalities.

Current penalty structures include:

| Violation Type | Maximum Penalty (2025) | Additional Consequences |

| Serious violations | $16,550 per violation | Production interruptions |

| Willful/repeated violations | $165,514 per violation | Increased insurance premiums |

| Failure to abate | $16,550 per day | Lost contracts |

OSHA issued $364 million in total fines in 2023, reflecting heightened enforcement priorities. A crane collapse in Texas resulted in a developer paying over $800 million to the deceased’s estate and family, demonstrating the extreme financial liability risks of non-compliance.

Understanding these regulatory requirements prepares organizations for the documentation and inspection processes essential for successful compliance audits.

What Documentation Should Be Collected and Reviewed Before a Compliance Audit?

Documentation serves as the foundation for demonstrating compliance during lifting equipment audits. Proper documentation proves adherence to OSHA and ASME standards while protecting organizations from penalties and operational disruptions.

Which Maintenance and Inspection Records Are Required for Audit Readiness?

Maintenance and inspection records are detailed logs documenting all maintenance activities, monthly rope inspections, repairs, and part replacements required under 29 CFR 1910.179. These records must include:

- Daily inspection logs recording operator pre-use checks of critical components

- Monthly rope inspection documentation as mandated by OSHA regulations

- Third-party inspection certificates from qualified inspectors for periodic evaluations

- Load testing reports demonstrating equipment capacity verification

- Incident reports maintaining comprehensive operational safety documentation

Third-party inspection certificates must be available for review, demonstrating compliance with ASME B30 series requirements. Load testing reports are required documentation proving equipment operates within rated capacities and safety margins.

How Should Employee Training and Certification Documentation Be Prepared?

Employee training and certification documentation is comprehensive records proving operator qualification, rigger competency, and signaler training compliance. Organizations must maintain:

- Operator certification records including initial training, renewal dates, and competency assessments

- Rigger training documentation covering sling selection, load calculation, and rigging techniques

- Signaler qualification records demonstrating proper communication protocol training

- Supervisor safety training certificates proving management oversight capabilities

A 2023 industry analysis reveals 92% of construction firms struggle to find qualified workers, highlighting the critical importance of proper training documentation for compliance audits and operational safety.

What Types of Equipment Inventories and Manuals Need to Be Available?

Equipment inventories and manuals are manufacturer specifications, rated load documentation, and operational guidelines that must be readily accessible during audits. Required documentation includes:

- Manufacturer’s specifications detailing design limits, operating parameters, and safety features

- Rated load plates documentation proving equipment capacity markings comply with ASME standards

- Lift plans and load calculations demonstrating proper engineering analysis for complex operations

- Equipment certification documents from manufacturers confirming compliance with applicable standards

Equipment certification documents from manufacturers must be available, proving initial compliance with ASME B30 series requirements and OSHA regulations for safe operation.

This comprehensive documentation framework ensures audit readiness while supporting the next critical phase: conducting thorough pre-audit equipment inspections and assessments.

How Can You Inspect and Assess Your Lifting Equipment Prior to the Audit?

Pre-audit equipment inspection serves as your first line of defense against compliance failures. Systematic assessment of lifting equipment identifies potential violations before auditors arrive. This preparation phase determines whether your equipment meets OSHA and ASME standards.

The following subsections detail common pre-audit issues, deficiency management procedures, and verification steps to ensure audit readiness.

What Are the Most Common Issues Found During Lifting Equipment Pre-Audits?

The most common issues found during lifting equipment pre-audits include hook deterioration, structural defects, and rope degradation. ASME B30.10 identifies wear, damage, and deformation of hooks as primary inspection points requiring immediate attention. These hook issues often manifest as cracks, excessive wear patterns, or dimensional changes affecting load capacity.

Structural integrity problems in mobile cranes represent another frequent finding per 29 CFR 1910.180 requirements. These issues include:

- Boom section cracks or deformation

- Outrigger float damage or wear

- Counterweight attachment problems

- Frame structural defects

Hoisting rope degradation requires frequent inspection under 29 CFR 1910.179 standards. Wire rope failures account for significant safety incidents when deterioration goes undetected during routine assessments.

How Should Deficiencies or Wear in Lifting Equipment Be Addressed?

Deficiencies or wear in lifting equipment should be addressed through immediate corrective action following established protocols. Implement a preventive maintenance program to address wear before equipment failure occurs, reducing downtime and safety risks.

Follow ASME B30.9 removal criteria for slings showing deficiencies such as:

- Cuts or snags affecting load-bearing capacity

- Heat damage or chemical deterioration

- Excessive wear beyond allowable limits

- Damaged hardware or fittings

Document all repairs and part replacements in maintenance logs with dates, technician signatures, and detailed descriptions. This documentation proves compliance efforts during audits and tracks equipment reliability trends.

Replace components immediately when they exceed manufacturer specifications or ASME standards. Never attempt temporary repairs on critical load-bearing elements.

What Steps Can Be Taken to Verify Equipment Is Audit-Ready?

Equipment verification for audit readiness requires systematic validation of all compliance elements. Conduct special inspections after any modifications or repairs to ensure continued compliance with original specifications.

Verify all rated load plates and manufacturer specifications are current and legible. Missing or damaged load plates constitute immediate violations requiring replacement before audit commencement.

Ensure load testing reports are up-to-date and accessible with the following elements:

- Test date within required intervals

- Certified testing organization credentials

- Pass/fail results with specific measurements

- Technician certifications and signatures

Cross-reference equipment serial numbers with maintenance records to confirm inspection completeness. This verification process identifies gaps in documentation before auditors discover them, allowing time for corrective action.

Who Should Be Involved in the Lifting Equipment Compliance Audit Process?

A successful lifting equipment compliance audit requires coordinated participation from safety officers, maintenance staff, and management to ensure all regulatory requirements are met. The collaborative approach involves designated personnel with specific responsibilities for audit preparation, documentation review, and ongoing compliance maintenance.

What Are the Roles of Safety Officers and Maintenance Staff in Audit Preparation?

Safety officers ensure all personnel including operators, riggers, and signalers are properly trained and qualified according to OSHA standards. Their responsibilities include verifying current certifications, maintaining training documentation, and conducting competency assessments for crane operators and rigging personnel.

Maintenance staff are responsible for implementing rigorous inspection schedules including daily, monthly, and annual inspections required by 29 CFR 1910.179. They document all maintenance activities, rope inspections, repairs, and part replacements in detailed maintenance logs. Maintenance teams also coordinate third-party inspections and load testing to ensure equipment meets ASME B30 series requirements.

Key safety officer and maintenance staff audit preparation tasks include:

- Verifying operator certifications and training records are current

- Conducting pre-audit equipment inspections per ASME B30 standards

- Organizing maintenance documentation and inspection certificates

- Coordinating special inspections after modifications or repairs

How Can Management Facilitate a Smooth Compliance Audit?

Management must foster a strong safety culture championed at the leadership level and embraced by all employees throughout the organization. Leadership commitment to safety creates the foundation for successful audit outcomes and ongoing compliance maintenance.

Investing in training and recruitment programs addresses the skilled labor shortage affecting 92% of construction firms according to industry data. Management support for comprehensive training ensures qualified personnel operate lifting equipment safely and maintain proper documentation for audit readiness.

Management facilitates audit success through strategic resource allocation, clear safety policies, and accountability systems that prioritize compliance. This collaborative approach between management, safety officers, and maintenance staff creates a comprehensive framework for successful lifting equipment compliance audits and reduces the risk of violations that could result in penalties up to $165,514 per incident.

How Can You Ensure Ongoing Compliance and Readiness for Future Audits?

Ongoing compliance for lifting equipment requires systematic year-round practices and proactive audit preparation. This approach transforms compliance from a reactive burden into a strategic advantage that protects workers and business operations.

What Are Best Practices for Maintaining Lifting Equipment Compliance Year-Round?

Best practices for maintaining lifting equipment compliance year-round include implementing digital inspection systems, predictive maintenance programs, and continuous monitoring technologies. The lifting equipment inspection software market is projected to reach $870 million by 2031, reflecting widespread adoption of digital compliance solutions across industries.

Digital transformation enhances compliance through several key methods:

- Digital checklists and automated reporting improve compliance tracking accuracy and reduce human error

- Real-time equipment monitoring provides continuous safety data and early warning systems

- AI-powered defect recognition enhances inspection accuracy beyond traditional visual methods

- IoT devices for continuous safety monitoring enable 24/7 equipment health assessment

Predictive maintenance reduces failure risks by identifying wear patterns before equipment reaches critical thresholds. This data-driven approach aligns with ASME B30 standards while optimizing maintenance schedules and reducing unplanned downtime.

Organizations implementing these technologies report improved audit readiness and reduced compliance violations through consistent documentation and proactive hazard identification.

How Can Periodic Internal Audits Improve Long-Term Compliance?

Periodic internal audits improve long-term compliance by identifying potential hazards before they lead to incidents and establishing systematic continuous improvement processes. Regular internal audits help identify potential hazards before they lead to incidents, creating a proactive safety culture that exceeds minimum regulatory requirements.

A proactive systematic approach to continuous improvement reduces violation risks through structured evaluation cycles. This methodology enables organizations to address compliance gaps during routine operations rather than during high-pressure external audits.

Key benefits of periodic internal audits include:

- Early hazard identification before incidents occur

- Systematic documentation review ensuring records meet OSHA standards

- Training gap analysis identifying certification needs before audits

- Equipment condition assessment validating maintenance effectiveness

Digital transformation enables better tracking and documentation of compliance activities through centralized data management and automated reporting systems. This technological integration creates audit trails that demonstrate sustained compliance efforts and continuous improvement initiatives.

Internal audit schedules should align with OSHA inspection requirements while adding value through deeper analysis of safety trends and equipment performance data.

This comprehensive approach to ongoing compliance creates audit readiness as a natural outcome of daily operations, ensuring your organization maintains the highest safety standards while minimizing regulatory risks and protecting valuable lifting operations.

How Should You Approach Lifting Equipment Compliance Audits With Support from Tway Lifting?

Approaching lifting equipment compliance audits with professional support transforms a potentially stressful process into a structured path to enhanced safety and regulatory compliance. Tway Lifting’s comprehensive audit preparation services help organizations navigate complex OSHA and ASME requirements while identifying potential hazards before they become costly violations.

Can Tway Lifting Help Your Business Prepare for and Pass Compliance Audits?

Tway Lifting helps businesses prepare for and pass compliance audits through specialized industrial rigging inspection services designed to identify potential hazards before incidents occur. Expert services help organizations achieve and maintain compliance with OSHA and ASME standards by providing thorough pre-audit assessments and documentation reviews.

Professional audit preparation includes comprehensive equipment inspections following ASME B30 series requirements, documentation verification for maintenance logs and training records, and strategic planning to address identified deficiencies. Tway Lifting’s experienced team understands the specific requirements auditors examine, such as:

- Monthly rope inspection documentation per 29 CFR 1910.179

- Load testing reports and certification documents

- Operator training records and safety program documentation

- Equipment inventory alignment with manufacturer specifications

This proactive approach reduces violation risks and helps organizations avoid the average $16,550 penalty per serious violation, while ensuring operations meet the highest safety standards.

What Are the Key Takeaways About How to Prepare for a Lifting Equipment Compliance Audit We Covered?

The key takeaways about preparing for lifting equipment compliance audits include establishing comprehensive documentation systems, implementing rigorous inspection schedules, and maintaining ongoing compliance through professional support and digital tracking solutions.

Critical preparation elements involve understanding OSHA regulations in 29 CFR 1910.179 and 1910.180, maintaining detailed maintenance logs with monthly rope inspections, and ensuring all personnel have current training certifications. Organizations must address the skilled labor shortage affecting 92% of construction firms by investing in proper training documentation and qualification programs.

Successful audit preparation requires proactive deficiency identification and remediation, comprehensive equipment inventories with manufacturer specifications, and implementation of preventive maintenance programs following ASME B30 series standards. The lifting equipment inspection software market’s projected growth to $870 million by 2031 reflects the increasing importance of digital compliance tracking and automated reporting systems.

Professional support from experienced providers like Tway Lifting transforms compliance from a reactive burden into a strategic safety advantage, helping organizations avoid the severe consequences of non-compliance while building robust safety cultures that protect workers and operations.