Proof-load testing is a critical safety verification procedure that applies controlled loads to lifting equipment to validate structural integrity and operational safety before workplace use. If you’re responsible for lifting operations or workplace safety, understanding proof-load testing requirements helps prevent accidents, ensure regulatory compliance, and protect your workforce from the 297 crane-related fatalities that occurred between 2011-2017 in the United States.

According to the Bureau of Labor Statistics, 2017: 80% of crane accidents result from exceeding equipment capacity. In 2020, industry expert Peter Hansen, President & CEO of Tway Lifting, emphasized: “Building a Wire Rope Products Plant in Indiana strengthened our position with the industrial sector in The Midwest.”

Static testing applies 125% rated capacity for 10 minutes, while dynamic testing uses 110% capacity for 1 hour. Overhead cranes require 1.0-1.25x WLL testing per 29 CFR 1910.179. Hoists need 1.0-1.25x WLL per ASME B30.16. Chain slings demand 2.0x WLL testing. Shackles require 2.0x WLL verification. Spreader beams need 1.25-2.0x WLL. Below-hook devices mandate 1.0-1.25x testing. Manual jacks must display rated loads. Proof-loading prevents 80% of capacity-related accidents through systematic verification. OSHA violations incur $14,502 penalties per serious infraction. Testing ensures $6 ROI per $1 invested in safety. Real-time IoT monitoring tracks equipment performance continuously. Competent personnel conduct monthly inspections systematically. Qualified professionals perform annual certifications thoroughly.

Implement quarterly equipment audits tracking test dates, load ratings, and certification expiration to maintain continuous compliance. This introduction establishes proof-load testing’s critical role in preventing equipment failures while highlighting Tway Lifting’s expertise in delivering comprehensive testing services that protect your operations and workforce.

How Does Proof-Load Testing Work for Lifting Equipment?

Proof-load testing works by applying controlled loads beyond normal operating capacity to verify structural integrity and performance of lifting equipment. This systematic process uses specialized procedures, equipment-specific protocols, and standardized guidelines to ensure safety compliance before equipment returns to service.

What Procedures Are Involved in Proof-Load Testing?

Static load testing involves applying 125% of rated capacity for 10 minutes, held 4 inches off ground, to assess structural integrity and check for permanent deformation. Dynamic load testing uses 110% of rated capacity for minimum 1 hour with all mechanisms operated to evaluate performance under working conditions.

Test loads must not exceed 125% of rated capacity unless manufacturer specifies otherwise per OSHA regulations. Operational load rating should not exceed 80% of maximum test load according to OSHA standards.

Modern testing employs advanced equipment such as:

- Water-filled proof load bags that provide gradual load application versus sudden application with solid weights, with capacity range from 1 to 110 tonnes

- Wireless load monitoring systems that handle up to 126 simultaneous connections with data logging speeds up to 200Hz

- Certification systems that automatically generate digitally signed pass/fail certificates with PDF reports for printing, emailing, or cloud uploading

These procedures verify equipment meets safety standards while creating documented proof of compliance for regulatory requirements.

Which Equipment Typically Requires Proof-Load Testing?

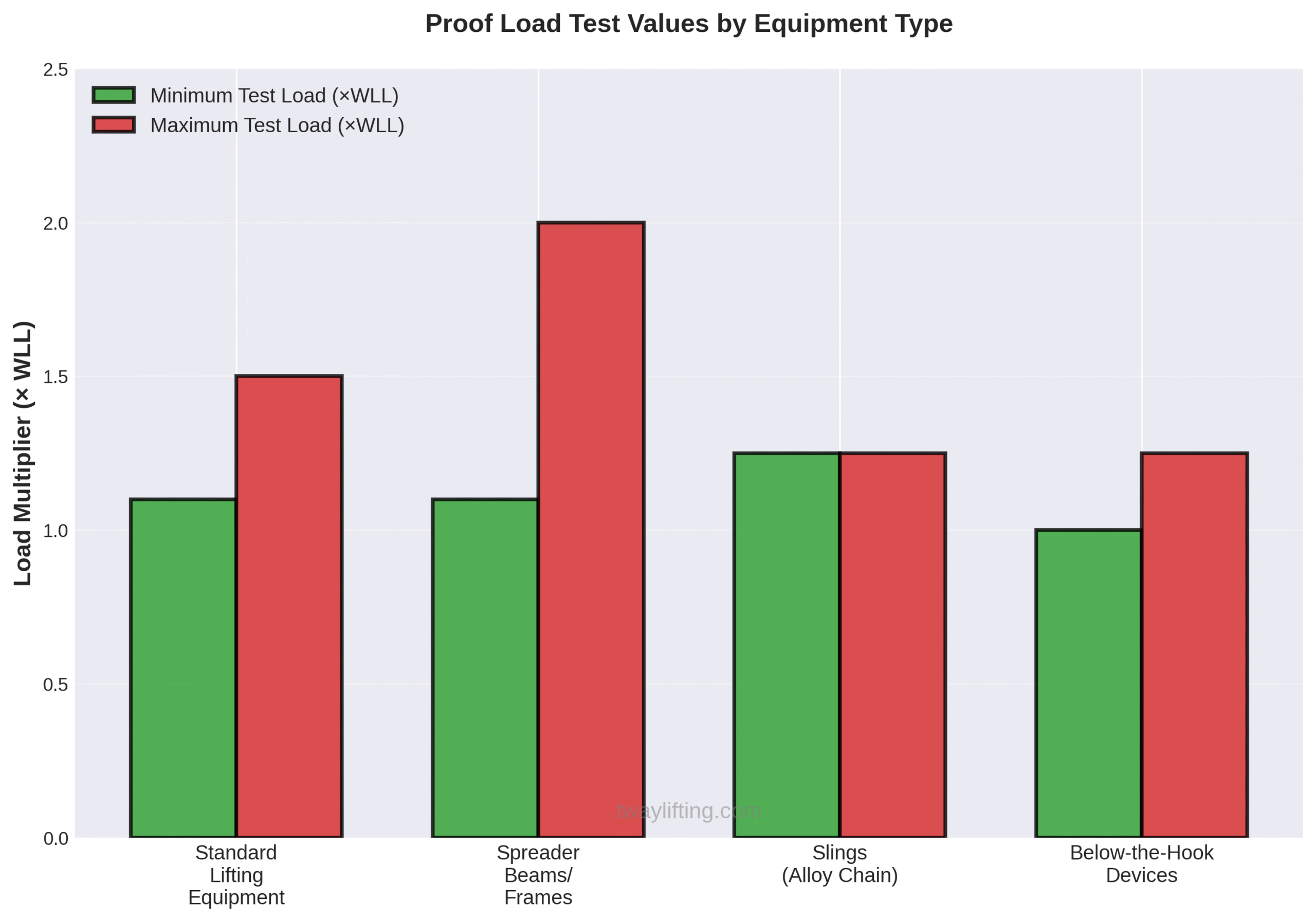

Equipment requiring proof-load testing includes cranes, hoists, rigging hardware, and specialized lifting devices, each with specific testing requirements based on working load limits and safety standards.

| Equipment Type | Testing Requirement | Standard |

| Overhead/Gantry Cranes | 1.0 to 1.25 times WLL | 29 CFR 1910.179 |

| Hoists | 1.0 to 1.25 times WLL | ASME B30.16 |

| Chain/Wire Rope Slings | 2.0 times WLL | ASME B30.9 |

| Rigging Hardware | 2.0 times WLL | ASME B30.26 |

| Spreader Beams | 1.25 to 2.0 times WLL | ASME BTH-1 |

| Below-Hook Devices | 1.0 to 1.25 times WLL | ASME B30.20 |

Manual pallet jacks must have rated loads posted per 29 CFR 1910.244(a)(1)(ii), with OSHA issuing a $5,795 fine in 2017 for non-compliance. This comprehensive testing scope ensures all lifting equipment meets established safety thresholds.

What Standards and Guidelines Govern Proof-Load Testing Processes?

29 CFR 1910.179 serves as the core regulation governing overhead and gantry cranes, with 29 CFR 1910.179(k)(2) mandating load testing for new and altered cranes. OSHA has stated that ANSI B30.2-2005 does NOT meet the protective standards of 29 CFR 1910.179(k).

CMAA Specification 78 requires written reports to be kept for entire equipment lifespan. Test reports must be filed and accessible to authorized personnel per OSHA requirements. OSHA regulations are legally binding while ASME standards are voluntary but often incorporated by OSHA.

Both OSHA and ASME require testing at 100% to 125% of rated load for new, altered, repaired, or modified equipment. These standards create a framework ensuring consistent safety protocols across industries and equipment types.

The next section explores the key benefits and purposes that make proof-load testing essential for workplace safety and regulatory compliance.

What Are the Key Benefits and Purposes of Proof-Load Testing?

Proof-load testing serves multiple critical purposes including accident prevention, regulatory compliance, and operational efficiency. The testing validates equipment capacity under controlled conditions while identifying potential failures before they occur in real-world applications.

How Does Proof-Load Testing Prevent Equipment Failure and Accidents?

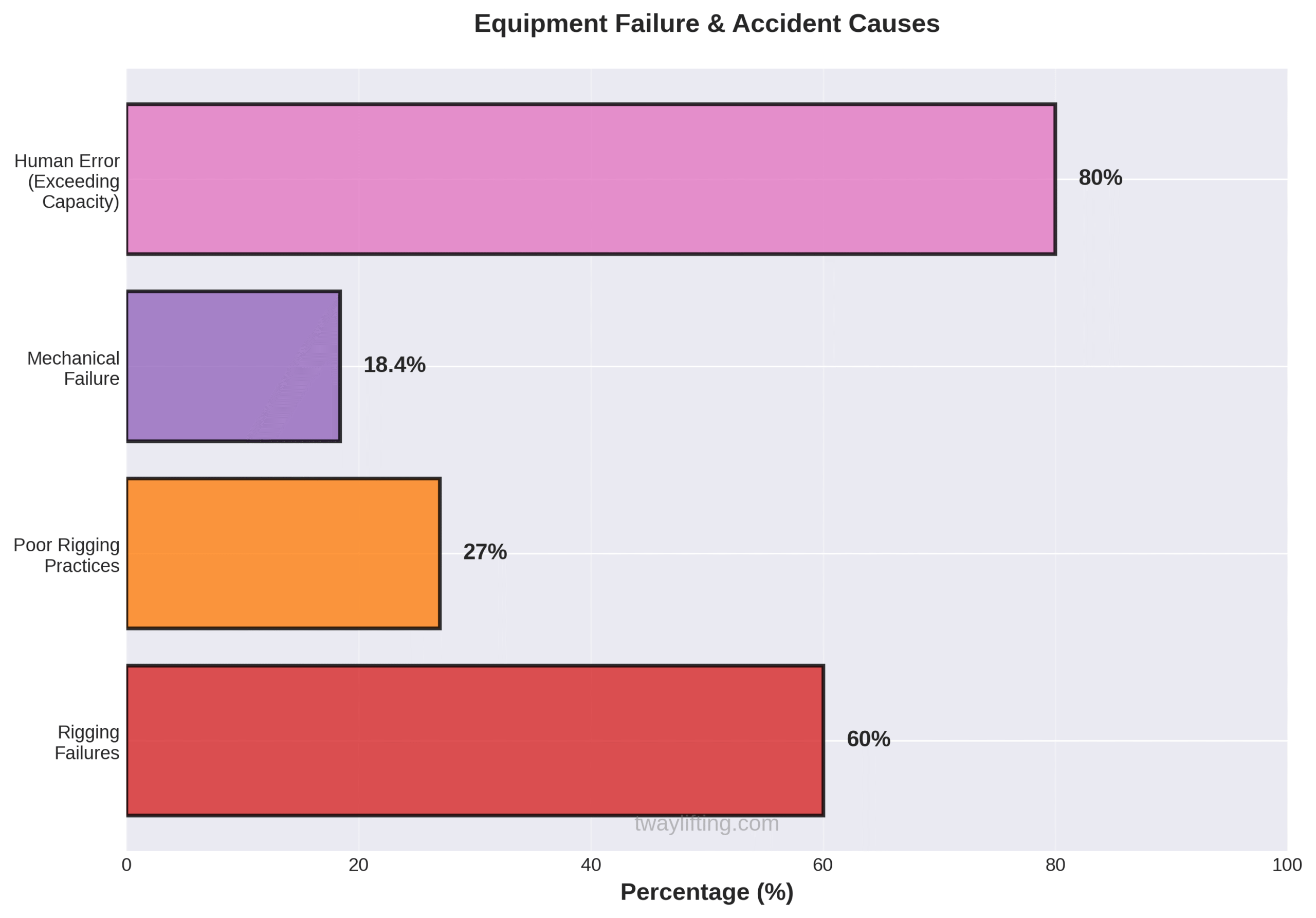

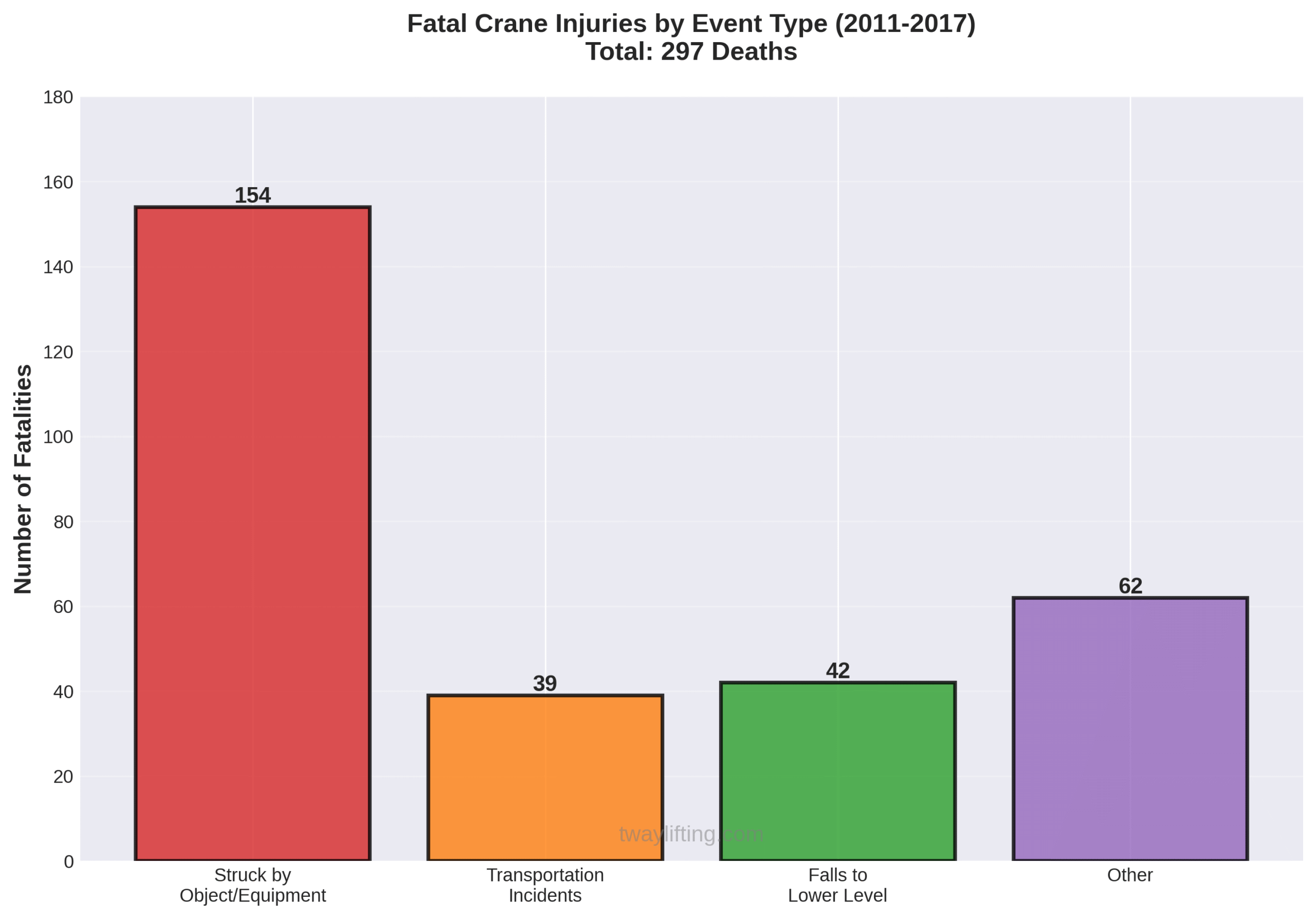

Proof-load testing prevents equipment failure by identifying structural weaknesses before catastrophic incidents occur. According to Bureau of Labor Statistics data from 2011-2017, 297 total crane-related fatalities occurred in the United States, with 80% of crane accidents caused by exceeding equipment capacity.

The testing reveals dangerous conditions through controlled stress application:

- Mechanical failure accounts for 18.4% of lifting incidents

- Poor rigging practices cause 27% of accidents

- 60% of fatal crane injuries involving struck-by incidents link to falling materials

- 154 fatalities (51.9% of total) resulted from being struck by objects or equipment

Modern proof-load testing incorporates real-time performance monitoring through IoT sensors that track vibration, temperature, and energy usage. Predictive maintenance alerts identify potential problems before failure occurs, supporting OSHA’s mandatory testing requirements in North America.

This systematic approach addresses the primary failure modes that led to crane-related incidents, providing measurable safety improvements through early detection of equipment degradation.

Why Is Proof-Load Testing Important for Regulatory Compliance?

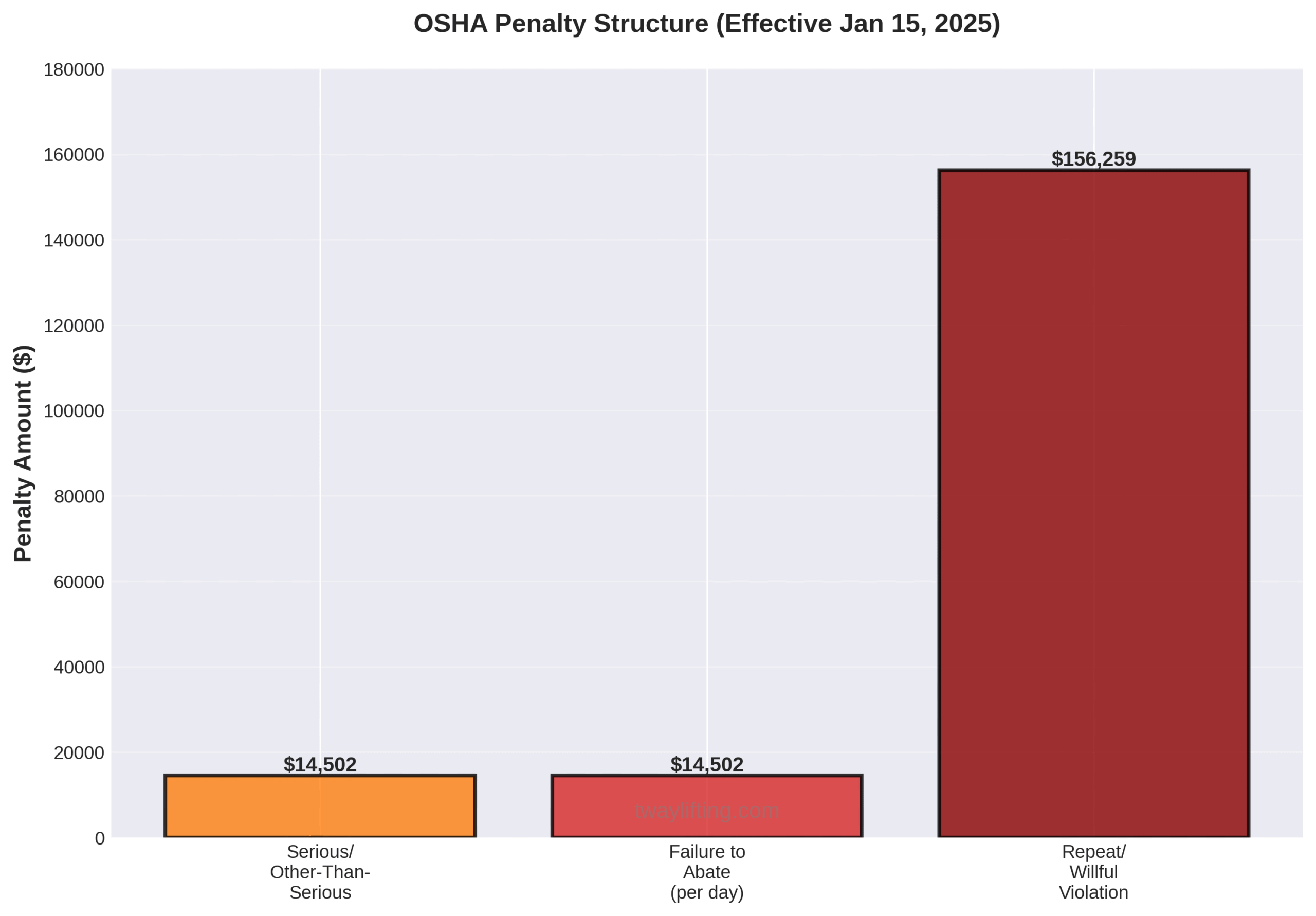

Proof-load testing ensures regulatory compliance by meeting OSHA’s mandatory requirements for lifting equipment verification. As of January 15, 2025, serious OSHA violations carry maximum penalties of $14,502 per violation, with escalating consequences for non-compliance.

OSHA Penalty Structure:

| Violation Type | Penalty Range | Additional Consequences |

| Minor to Serious | $1,190 – $161,323 | Per violation assessment |

| Serious Violations | $14,502 | Maximum per violation |

| Failure to Abate | $14,502 | Per day beyond deadline |

| Repeat/Willful | $156,259 | Maximum per violation |

Load testing serves as legally required documentation for architects, project managers, building managers, and design engineers during job planning phases. Insurance claims support relies on reliable testing records that help with claims processing, reduce disputes, and support warranty extensions.

International compliance varies significantly—UK LOLER penalties include prison sentences of 6 months to 2 years plus substantial fines for non-compliance, demonstrating the global emphasis on lifting equipment verification.

How Can Proof-Load Testing Improve Workplace Efficiency and Trust?

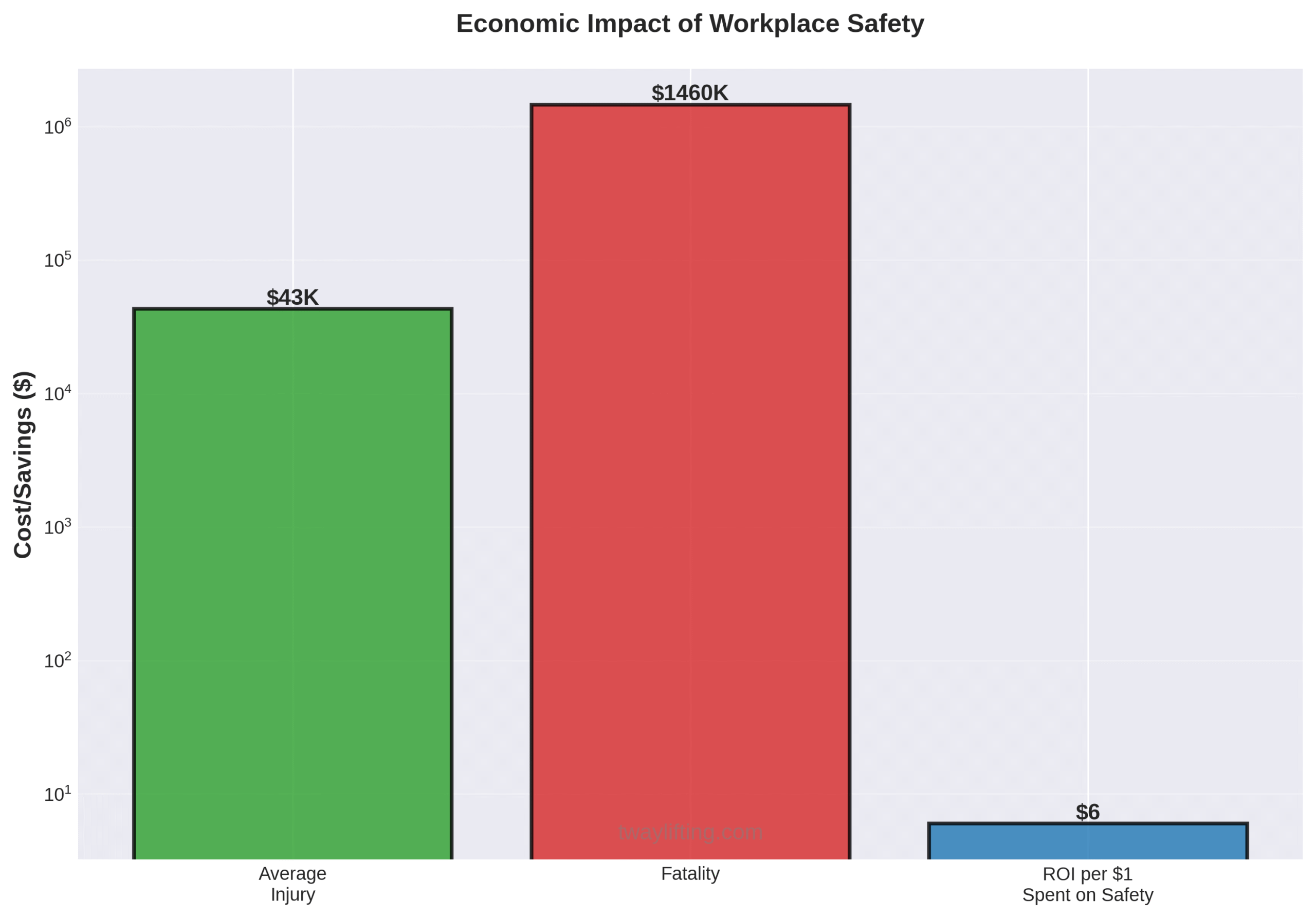

Proof-load testing improves workplace efficiency by delivering measurable returns on safety investments while reducing operational disruptions. Companies save $6 for every $1 spent on workplace safety investments, representing a 600% return on investment according to safety performance studies.

Operational Benefits Include:

- Fewer disruptions to operations through OSHA compliance

- Lower insurance premiums for compliant businesses

- Reduced downtime through preventive maintenance programs

- Higher employee morale and retention in organizations with strong safety culture

- Same-day or 2-day turnaround for chain sling reconditioning in most cases

Reliable documentation helps reduce warranty disputes and supports equipment warranty extensions through verified performance records. This systematic approach builds trust between management and workers by demonstrating measurable commitment to safety protocols.

The efficiency gains compound over time as predictive maintenance identifies issues during scheduled downtime rather than emergency repairs, minimizing production interruptions while maintaining regulatory compliance standards.

These combined benefits position proof-load testing as essential infrastructure for safe lifting operations while supporting business continuity and regulatory compliance across multiple jurisdictions.

When and How Often Should Proof-Load Testing Be Performed?

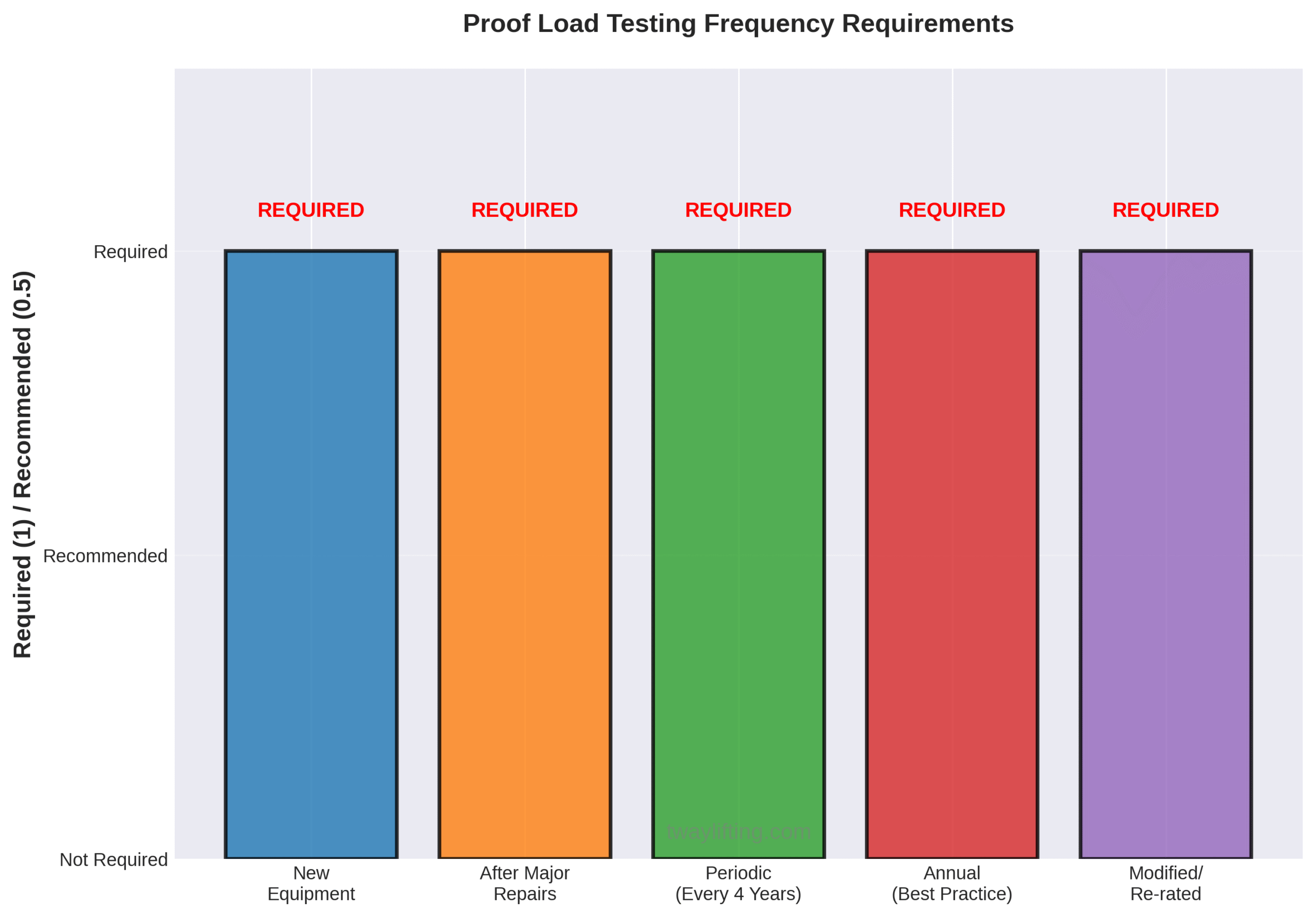

Proof-load testing frequency depends on equipment type, usage conditions, and regulatory requirements. New equipment requires mandatory testing before initial use, while existing equipment follows scheduled intervals based on risk factors and operational demands.

What Factors Influence the Frequency of Proof-Load Testing?

The factors that influence proof-load testing frequency include equipment condition, regulatory mandates, and operational changes. New equipment requires mandatory testing before initial use to verify structural integrity and load-bearing capacity. Equipment must be tested after major repairs before return to service to ensure modifications maintain safety standards. Modified or re-rated equipment needs mandatory testing before return to service according to OSHA regulations.

Regulatory schedules establish minimum testing intervals:

- Unit proof tests are mandatory every 4 years per regulations

- Annual testing represents best practice though not always mandatory

- Daily/pre-shift inspections must be conducted by operators before each use

- Monthly inspections are required by competent individuals

- Annual inspections must be performed by qualified personnel

Annual testing provides optimal safety assurance despite exceeding minimum requirements in many cases.

Are There Signs Your Lifting Equipment Needs Immediate Proof-Load Testing?

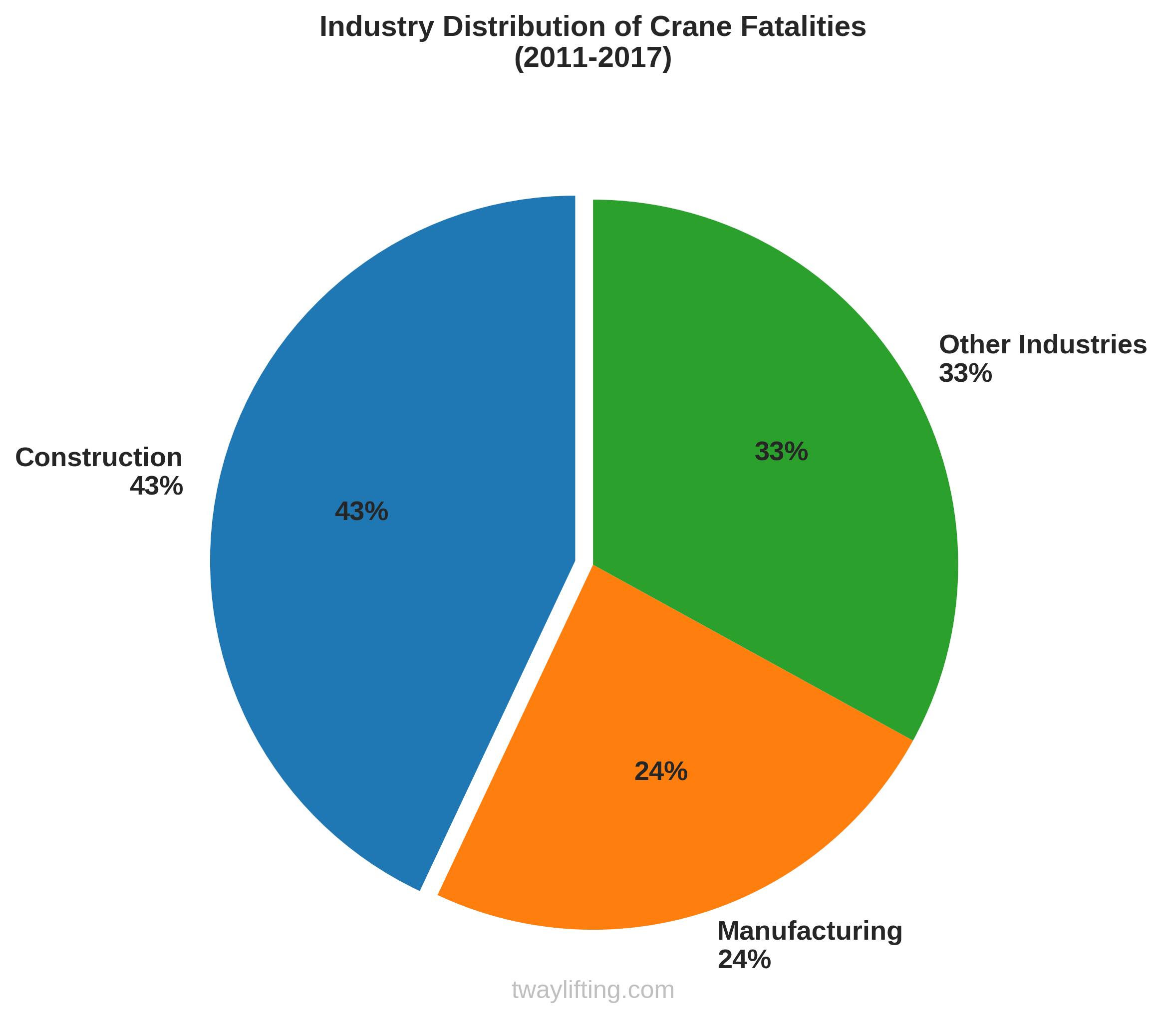

Signs that lifting equipment needs immediate proof-load testing include visible damage, operational irregularities, and industry risk indicators. Construction industry accounts for 43% of crane fatalities, indicating higher risk environments requiring more frequent testing. Manufacturing represents 24% of crane fatalities, suggesting industrial wear concerns that warrant immediate evaluation.

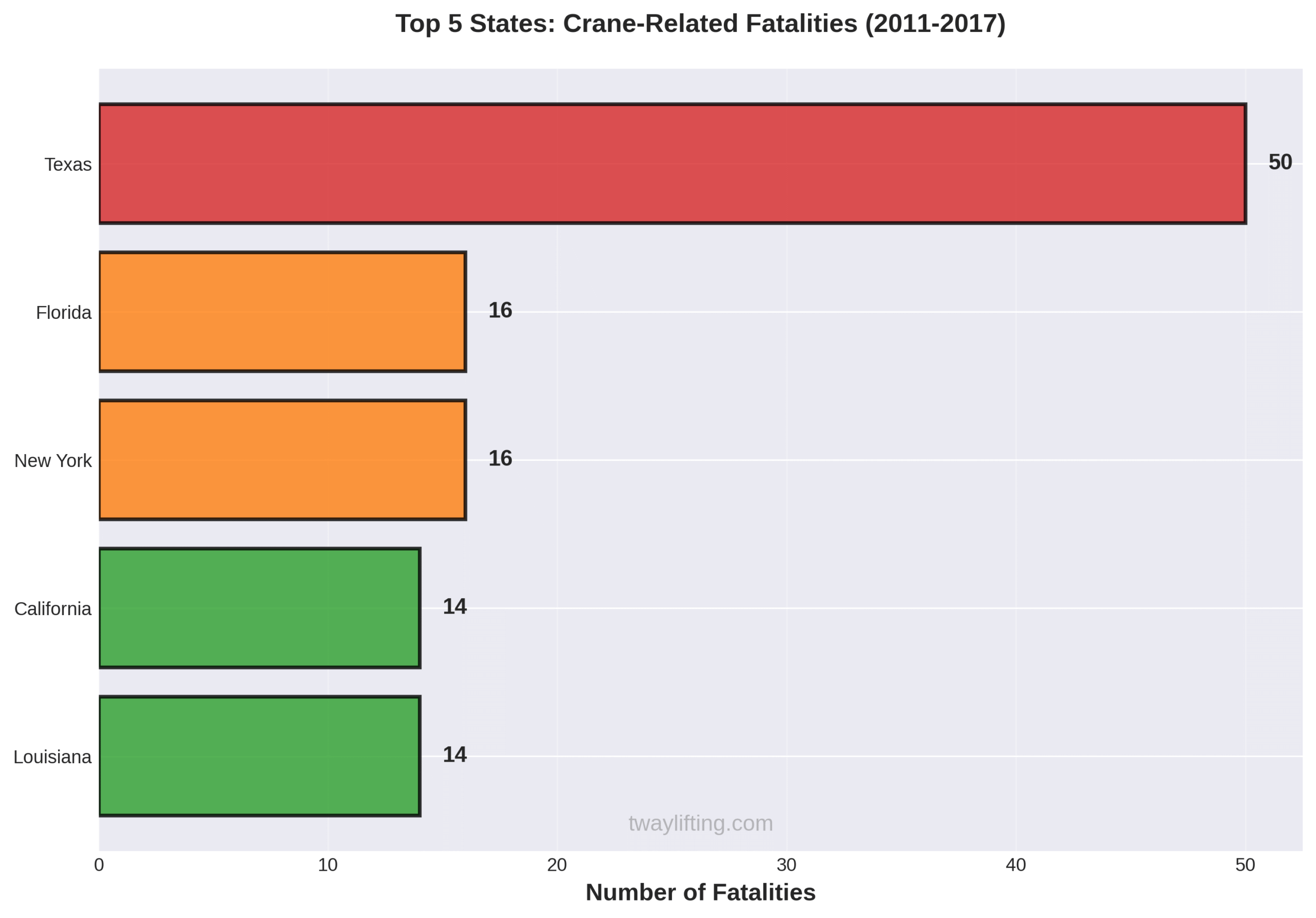

Geographic accident data reveals concentrated risk areas:

- Texas had 50 crane fatalities (highest in nation) between 2011-2017

- Florida and New York each had 16 fatalities during the same period

- 490 non-fatal crane incidents were reported in 2020

- Average of 42 crane-related fatalities occur per year based on 2011-2017 data

Equipment showing stress signs, unusual noises, or operating in high-fatality regions should undergo immediate testing regardless of scheduled intervals.

Who Is Qualified to Perform Proof-Load Testing?

Qualified personnel for proof-load testing varies by inspection type and equipment complexity. Competent individuals must conduct monthly inspections with demonstrated knowledge of equipment operation and hazard recognition. Qualified personnel are required for annual inspections possessing formal training and certification in testing procedures. Operators perform daily/pre-shift inspections focusing on visible defects and operational readiness.

According to Compliance Consultants, Inc., everyone involved in assembly, disassembly, rigging and operation must be properly trained, qualified and/or certified. Professional testing services ensure compliance with OSHA and ASME standards while providing certified documentation for regulatory compliance.

The next section examines the serious risks and consequences that result from skipping proof-load testing requirements.

What Are the Risks or Consequences of Skipping Proof-Load Testing?

Skipping proof-load testing creates severe legal, financial, and safety risks that can devastate businesses and endanger lives. Organizations face substantial OSHA penalties, expensive workplace injuries, and potential criminal liability when lifting equipment fails without proper testing verification.

What Legal and Financial Penalties Can Occur?

Legal and financial penalties for skipping proof-load testing range from thousands to hundreds of thousands of dollars per violation. According to OSHA’s 2025 penalty structure, serious violations result in $14,502 per violation, while failure to abate violations costs $14,502 per day beyond the compliance deadline. Repeat or willful violations can reach $156,259 per violation, with total penalty ranges spanning from $1,190 to $161,323 depending on severity.

Beyond regulatory fines, workplace incidents create massive financial burdens. The average workplace injury costs $43,000, while workplace fatalities average $1,460,000 in direct costs. These figures exclude indirect costs such as lost productivity, training replacements, and increased insurance premiums that compound the financial impact.

How Can Skipping Proof-Load Testing Impact Employee Safety?

Skipping proof-load testing directly endangers employee lives, as evidenced by 297 total crane-related fatalities between 2011-2017. Workers face multiple fatal hazards when lifting equipment lacks proper testing verification.

The most common fatality causes include:

- 154 workers died from being struck by objects/equipment (51.9% of fatalities)

- 42 workers died from falls to lower level (14.1% of fatalities)

- 39 workers died in transportation incidents (13.1% of fatalities)

Nearly 60% of fatal crane injuries involving workers struck by objects link to falling materials from equipment failures. Beyond fatal incidents, 490 non-fatal crane incidents occurred in 2020 alone, representing serious injuries that proper testing could prevent.

What Are Common Incidents Linked to Lack of Proof-Load Testing?

Common incidents from inadequate proof-load testing stem from predictable equipment failures that testing identifies before catastrophic breakdown. Research shows 80% of crane accidents result from exceeding equipment capacity—a condition proof-load testing specifically addresses by verifying safe working limits.

Additional incident patterns include:

- 60% of fatal injuries from struck-by incidents involve falling materials

- 27% of accidents stem from poor rigging practices

- 18.4% of incidents trace to mechanical failure

The United States averages 42 crane-related fatalities annually based on 2011-2017 data, with many incidents preventable through proper proof-load testing protocols. Equipment failures cascade through jobsites, creating multi-victim incidents that proper testing prevents by identifying structural weaknesses before catastrophic failure occurs.

This data demonstrates how proof-load testing serves as a critical safety barrier, preventing equipment failures that lead to worker injuries, fatalities, and massive financial consequences for unprepared organizations.

Ready to Strengthen Your Lifting Operations with Proof-Tested Spreader Bar Rentals?

Tway Lifting ensures every spreader bar rental meets or exceeds OSHA and ASME standards through certified proof-load testing, detailed inspection, and full documentation. Our ISO-aligned testing infrastructure guarantees that each rental unit arrives job-ready, traceable, and compliant for immediate safe use.

Can You Rent Proof-Tested Spreader Bars from Tway Lifting?

Yes, you can rent Proof-Tested Spreader Bars from Tway Lifting, each accompanied by a current Certificate of Test, inspection record, and RFID-tracked history for [safe and compliant lifting operations]. Every spreader bar in our rental fleet undergoes hydraulic proof-load testing between 125%–200% of its rated capacity to ensure structural integrity and regulatory compliance. Whether you need adjustable, fixed, or modular configurations, Tway’s certified spreader bar rentals deliver safety assurance, efficiency, and reliability backed by over 75 years of lifting experience.

Is Proof-Load Testing Important for Spreader Bar Rentals?

Absolutely. Proof-load testing verifies that every rental spreader bar performs safely at or above its rated load, eliminating the risk of undetected stress or structural fatigue. It’s not only a compliance requirement—it’s a safeguard for your crew and your project. Renting from Tway Lifting means every bar you receive is certified, traceable, and ready for the field with full OSHA and ASME documentation, ensuring total confidence in every lift.

What Are the Key Takeaways About Proof-Load Testing and Its Importance for Lifting Equipment?

The key takeaways about proof-load testing center on accident prevention, financial benefits, and regulatory compliance requirements. Proof load testing prevents 80% of crane accidents caused by exceeding equipment capacity, while companies achieve a return on investment of $6 saved for every $1 spent on workplace safety.

Testing requirements vary by equipment type:

| Equipment Type | Testing Requirement | Compliance Standard |

| New Equipment | 100-200% of WLL | OSHA Mandatory |

| After Repairs | 100-200% of WLL | OSHA Mandatory |

| Modified Equipment | 100-200% of WLL | OSHA Mandatory |

OSHA penalties range from $1,190 to $156,259 per violation, with potential prison sentences internationally for non-compliance. These financial and legal consequences make proof-load testing essential for operational sustainability.

According to Peter Hansen, President & CEO, “Building a Wire Rope Products Plant in Indiana strengthened our position with the industrial sector in The Midwest.” Quality products and well-trained staff have made Tway Lifting the leader in rigging equipment for over 70 years, demonstrating the long-term value of professional testing partnerships.

These takeaways emphasize that proof-load testing represents both a safety imperative and a business investment that protects personnel, equipment, and organizational compliance across all lifting operations.