When you’re tasked with moving or storing spreader bars, you’re handling critical lifting equipment that demands respect and proper procedures. We understand that protecting these valuable assets while ensuring workplace safety can feel overwhelming, especially with complex regulations and potential hazards at every turn. You’re in the right place to master the essential practices that keep your equipment functional, your team safe, and your operations compliant with industry standards.

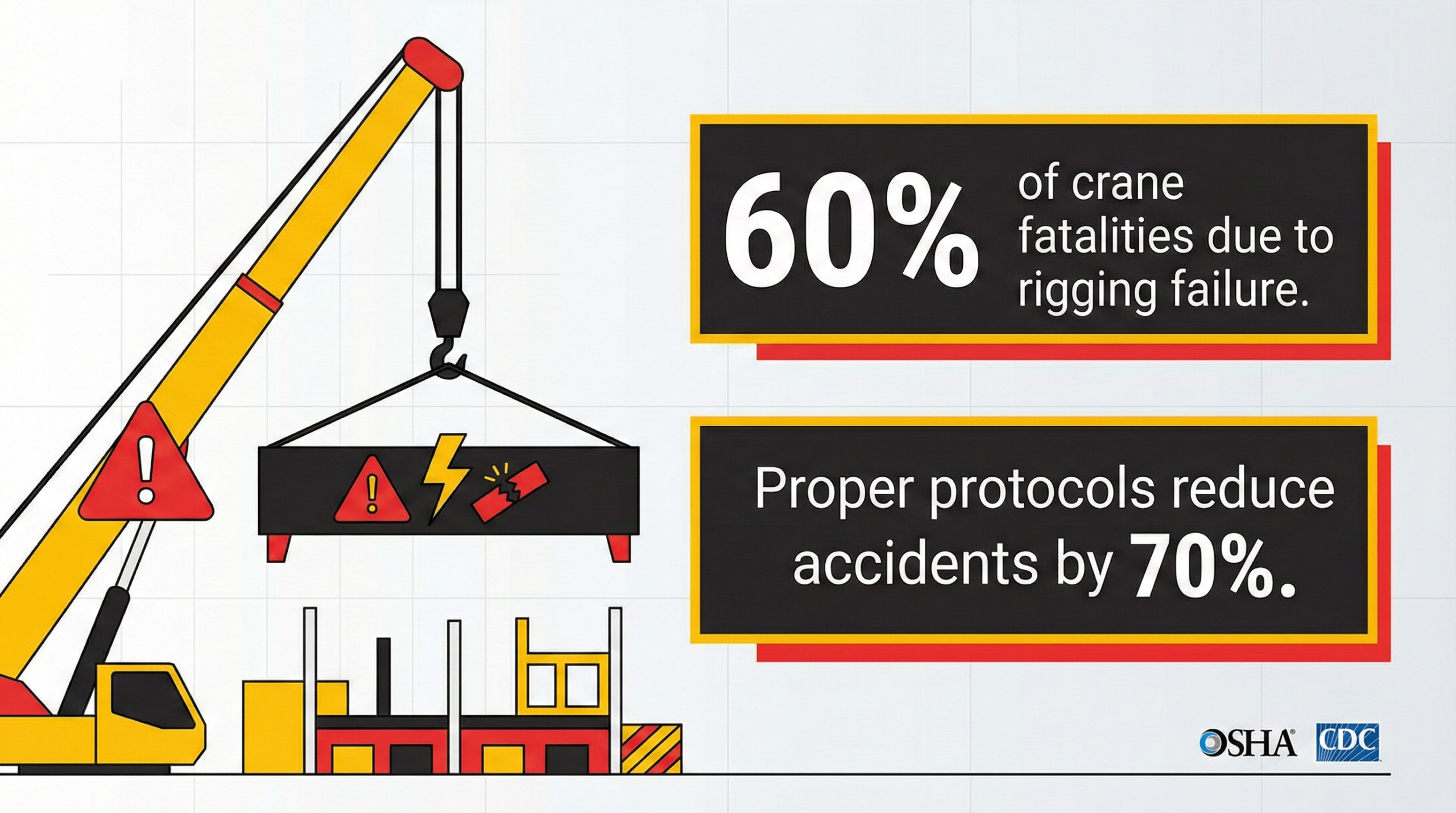

Transporting and storing spreader bars safely is a systematic process that requires proper preparation, appropriate equipment, controlled environmental conditions, and regular inspections to prevent accidents and equipment degradation. According to CDC studies, rigging failures are responsible for 60% of crane-related fatalities, making proper handling procedures critical for workplace safety. When companies implement comprehensive safety protocols for spreader bar transport and storage, they reduce accident risks by up to 70% while extending equipment lifespan and maintaining operational efficiency.

TL;DR Summary: This comprehensive guide covers essential safety protocols for spreader bar handling, from identifying risks and using proper PPE to implementing best practices for transport and storage. We detail regulatory compliance requirements under OSHA and ASME standards, explain optimal storage conditions to prevent corrosion, outline inspection and maintenance schedules, and demonstrate how partnering with experienced providers like Tway Lifting ensures both safety and compliance throughout your lifting operations.

Quick Tip: Always inspect spreader bars before and after transport for any cracks, deformation, or damaged hardware—even hairline cracks compromise structural integrity and require immediate equipment removal from service.

What Safety Risks Should You Consider When Handling Spreader Bars?

Spreader bar safety risks include structural failures, improper handling procedures, inadequate personal protection, and environmental hazards that can result in serious injuries or fatalities. According to CDC studies, rigging failures are responsible for 60% of crane-related fatalities, making proper risk assessment essential for safe operations. Understanding these risks helps operators implement effective prevention strategies and maintain compliance with OSHA safety standards.

The following sections examine how improper handling leads to accidents, essential protective equipment requirements, and environmental factors that affect spreader bar safety during operations.

How Might Improper Handling of Spreader Bars Lead to Accidents?

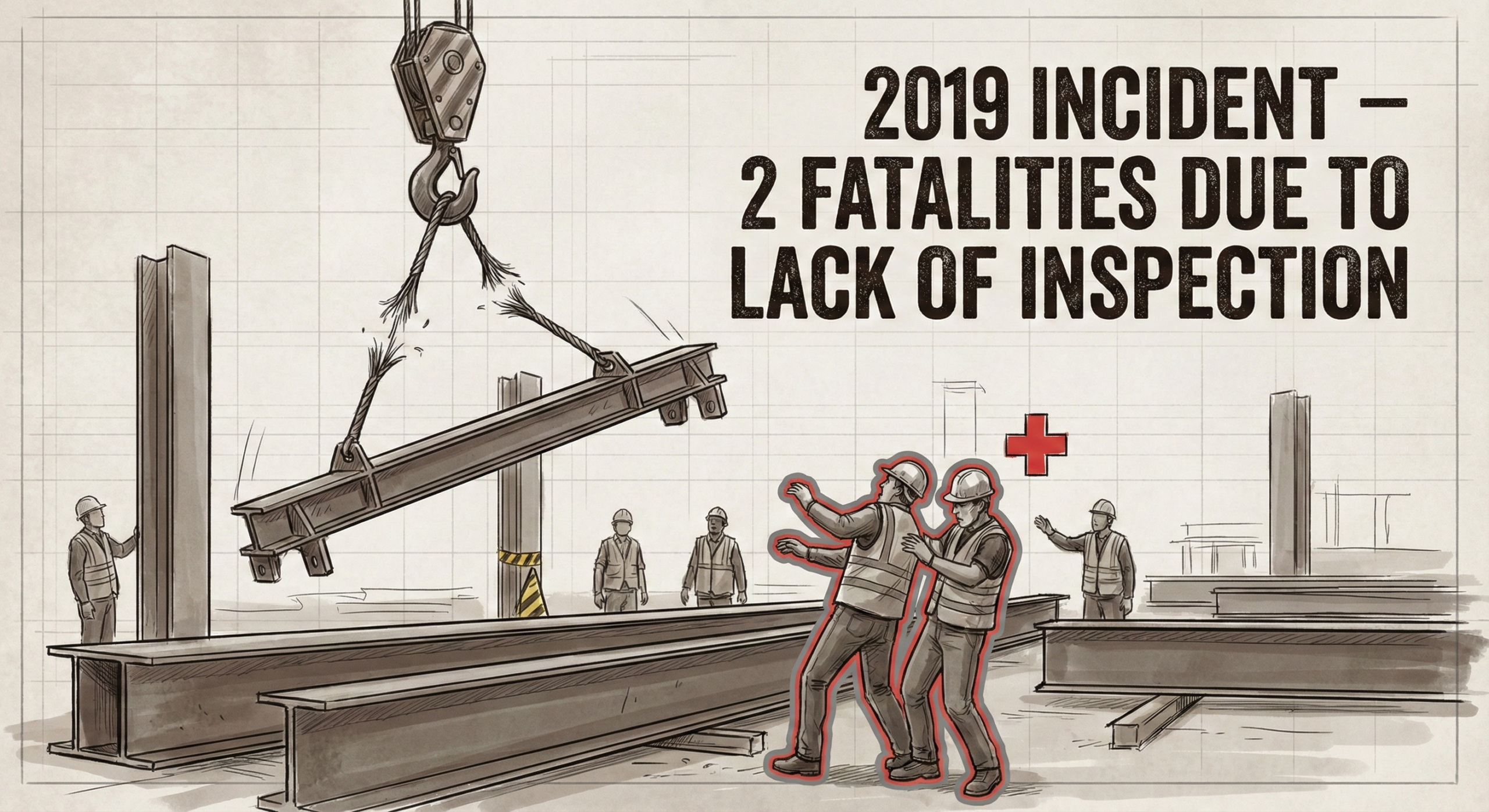

Improper handling of spreader bars leads to accidents through structural failures, inadequate inspections, and poor rigging practices that result in equipment drops and worker fatalities. A 2019 fatal workplace accident at an industrial facility killed two workers when a 2,500-pound spreader bar with severed wire rope fell from a crane due to lack of inspection protocols. Over 50% of crane-related fatalities result from workers being struck by objects or equipment.

Critical handling failures include:

- Inspection neglect: Any crack in spreader bar components, regardless of size, compromises structural integrity and creates failure risk during operation

- Poor rigging practices: A study examining 249 industrial overhead crane incidents found that 27% of load drops were directly tied to poor rigging practices

- Incorrect sling angles: Improper sling angles can reduce effective load capacity by up to 50% when angles drop below 30 degrees

- Power line contact: OSHA found that 45% of crane accidents are caused by the boom or crane making contact with energized power lines

These handling errors demonstrate why rigorous training and inspection protocols are essential for preventing workplace fatalities and equipment damage.

What Personal Protective Equipment Is Recommended When Moving Spreader Bars?

Personal protective equipment recommended when moving spreader bars includes flame-resistant clothing, safety shoes, hard hats, protective gloves, safety harnesses, and eye protection to prevent injuries from falling objects, chemical exposure, and electrical hazards. Studies show that PPE can lower injury rates by up to 60%, while following rigging rules and doing risk checks can cut accidents by up to 70%.

Essential PPE components include:

- Protective clothing: Flame-resistant materials provide protection during rigging tasks

- Safety shoes: Slip-resistant soles with protection against sharp objects and chemical exposure

- Hard hats: Protection from falling objects and impact injuries

- Safety gloves: Thermal, chemical, and mechanical injury prevention

- Safety harnesses: Fall protection for elevated work areas

- Safety glasses: Eye protection from chemicals, welding sparks, and debris

OSHA mandates PPE usage in lifting and rigging scenarios, especially when there’s risk of falling objects, electrical hazards, or high-traffic zones. When companies provide comprehensive training, accidents and injuries drop by 40%.

What Environmental Factors Can Affect Spreader Bar Safety During Transport or Storage?

Environmental factors that affect spreader bar safety during transport or storage include humidity levels, temperature fluctuations, chemical exposure, and atmospheric conditions that cause corrosion and material degradation. Excess humidity leads to rust, while fluctuating temperatures can cause material degradation that compromises equipment integrity over time.

Key environmental considerations include:

- Humidity control: Relative humidity should be maintained below 60 percent to prevent corrosion

- Chemical exposure: Exposure to acids, alkalis, exhaust emissions, and strong chemicals during transport and storage can compromise equipment integrity

- Temperature extremes: Equipment should not be exposed to flame or extreme temperatures

- Atmospheric monitoring: IoT-enabled sensors enable adaptation to changing environmental conditions like wind and temperature for improved safety and precision

The severity of the operational environment, including storage and transportation conditions, significantly influences spreader bar performance and longevity. Proper environmental management protects equipment from premature failure and maintains structural integrity throughout the equipment lifecycle.

What Are the Best Practices for Transporting Spreader Bars?

The best practices for transporting spreader bars include proper preparation, using certified equipment, secure cargo restraint, and strict regulatory compliance. These practices prevent equipment damage, ensure worker safety, and maintain legal compliance during transport operations.

How Should You Prepare Spreader Bars for Transport?

Proper preparation for transport begins with thorough cleaning of all equipment after each use, removing dirt, moisture, and debris that could cause corrosion during transit. All equipment must be completely dried before storage to prevent moisture buildup that leads to structural deterioration.

Essential preparation steps include:

- Apply protective coatings to prevent corrosion during transport

- Verify manufacturer’s name, serial number, rated load, and required markings remain present, accurate, and legible for regulatory compliance

- Check for bent, cracked, or deformed components indicating structural compromise requiring immediate equipment removal

- Inspect shackles for proper pin engagement and secure locking mechanisms that prevent accidental disengagement

- Ensure all hardware components maintain proper ratings for intended loads, as undersized components create catastrophic failure risks

Any crack in spreader bar components, regardless of size, compromises structural integrity and creates failure risk during operation, requiring immediate removal from service.

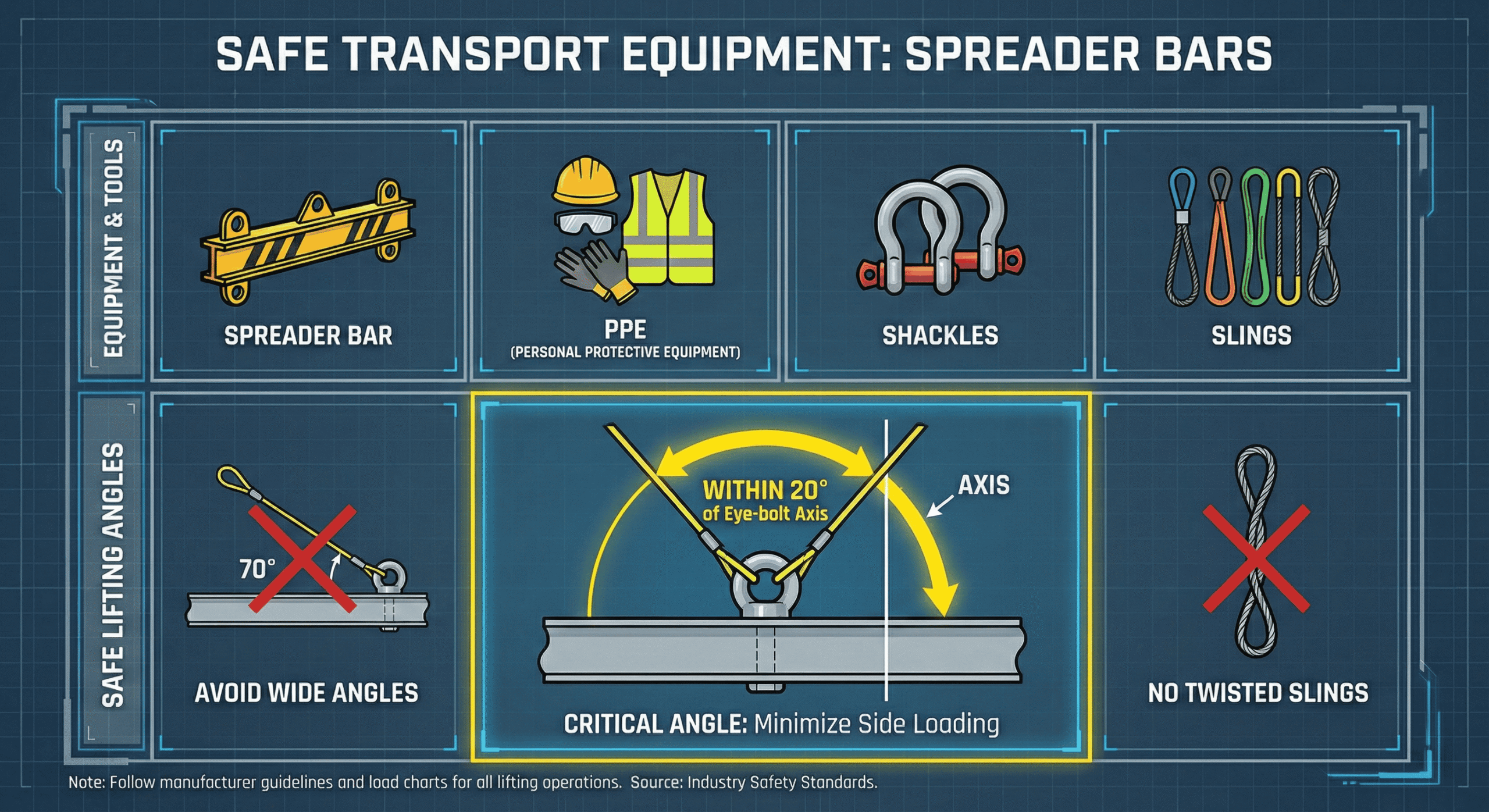

What Equipment Is Needed to Safely Move Spreader Bars?

Equipment requirements for safe spreader bar transport center on engineer-certified devices and proper personal protective equipment. Use only an engineer-certified spreader bar that displays a clearly labeled decal showing year of manufacture, maximum weights, and rated lift capacity.

Required equipment specifications include:

| Equipment Type | Requirements | Safety Features |

| Spreader Bar | Engineer-certified with current decal | Proper locks, retaining pins, anchor points, safety wrap chains |

| Personnel PPE | High-visibility vests and steel-toe boots | Protection during moving operations |

| Sling Arrangements | Within 20 degrees of eye-bolt axis | Prevents angular loading stress |

| Load Ratings | Never exceed safe working load | As prescribed on identification markings |

When slings are secured to eye-bolts, arrange them using spreaders if necessary so the pull is within 20 degrees of the axis of the bolt to prevent angular loading that reduces capacity.

How Can You Secure Spreader Bars During Transportation?

Spreader bar securement during transport follows FMCSA cargo securement rules to prevent shifting or falling during transit. All cargo must be secured using appropriate restraint systems, such as tie down straps, chains, or other approved devices that provide adequate holding force.

Critical securement requirements include:

- Securement systems must provide downward force equivalent to at least 20 percent of cargo weight if not fully contained

- Motor carriers must follow FMCSA cargo securement rules to prevent articles from shifting on or within, or falling from vehicles

- Spreader bars are classified as “suspended loads” for OSHA compliance purposes

- Operators cannot leave a crane unattended or leave controls with a suspended spreader bar

Proper securement protects both the equipment and public safety during transport operations.

What Regulations Govern the Transport of Spreader Bars in the US?

Federal regulations governing spreader bar transport include OSHA regulation 29 CFR 1926.251, which establishes rigging equipment requirements for material handling operations. This regulation incorporates ASME standards by reference, making compliance with ASME B30.20 legally binding in workplace settings.

Key regulatory requirements include:

- Custom-designed lifting accessories must undergo proof testing to 125% of rated capacity before initial use

- All rigging equipment requires inspection prior to each shift and during use as conditions necessitate

- Rated capacity must be legibly marked on all devices to ensure proper load limits are maintained

- Equipment must not be used without affixed, legible identification markings

According to OSHA 2023 data, violations related to crane and rigging safety ranked among the top 10 most frequently cited workplace violations, emphasizing the critical importance of regulatory compliance.

Following proper preparation, equipment certification, secure transportation methods, and regulatory compliance ensures safe spreader bar transport while protecting personnel and maintaining equipment integrity throughout the logistics chain.

How Should You Store Spreader Bars to Ensure Longevity and Safety?

Proper spreader bar storage requires specific environmental conditions, protective measures, and regular monitoring to prevent corrosion damage and maintain structural integrity. Storage practices directly affect equipment lifespan and operational safety.

What Storage Conditions Are Ideal for Spreader Bars?

Ideal storage conditions maintain spreader bars in a controlled environment that prevents moisture damage and structural degradation. Store spreader bars horizontally in a dry, well-ventilated shelter with relative humidity below 60 percent. Keep equipment off the ground using racks or pallets to prevent moisture accumulation from concrete floors.

Storage facilities require proper ventilation to prevent humidity buildup that accelerates corrosion. Avoid using tarps that trap moisture; use breathable covers when weather protection is needed. Use dehumidifiers, moisture-barrier films, or sealed containers in high-humidity environments to maintain optimal conditions.

These storage requirements connect directly to corrosion prevention strategies and inspection protocols outlined in the following sections.

How Can You Prevent Damage and Corrosion During Storage?

Preventing damage and corrosion during storage requires protective coatings, proper cleaning, and environmental controls. Epoxy coatings, galvanization, and thermal sprayed aluminum (TSA) are common corrosion prevention methods proven effective in marine environments. These protective coatings act as barriers against moisture and corrosive elements.

Clean spreader bars thoroughly before storage, removing dirt and debris that accelerate corrosion. Lubricate moving parts on adjustable spreader bars to prevent seizure and wear. Keep equipment away from acids, alkalis, exhaust emissions, and strong chemicals during storage.

A 2021 study on predictive maintenance using IoT sensors shows early detection reduces downtime by 40% and prevents failures through continuous monitoring. Proper cleaning and protective storage extend service life while maintaining equipment value for long-term operations.

How Often Should Stored Spreader Bars Be Inspected?

Stored spreader bar inspection frequency follows ASME B30.20 standards and regulatory requirements for different service classifications. All spreader bars must undergo annual inspection and certification according to Canadian law and ASME B30 standards. ASME B30.20 defines specific inspection intervals: Normal service requires monthly inspections, Heavy service requires weekly inspections, and Severe service requires daily inspections.

| Service Type | Inspection Frequency | Documentation Required |

| Special/Infrequent | As recommended | Annual certification |

| Normal Service | Monthly | Periodic records |

| Heavy Service | Every 14 days | Regular documentation |

| Severe Service | Every 3 days | Continuous monitoring |

Rigging equipment requires pre-shift inspection before each use and periodic inspections for thorough assessment of structural integrity, welds, and hardware condition. These inspection protocols ensure stored equipment remains safe and compliant.

What Are Common Mistakes to Avoid When Storing Spreader Bars?

Common storage mistakes compromise spreader bar integrity and create safety hazards during future operations. Never make unauthorized alterations to spreader bars during storage, as modifications compromise structural integrity and safety certifications. Avoid exceeding rated loads or using equipment beyond specified capabilities even during storage movements.

Storage-related mistakes include:

- Poor loading during storage repositioning

- Unauthorized modifications without manufacturer consent

- Inadequate protection from environmental hazards

- Excessive maintenance that increases downtime costs

A 2020 inspection analysis found that corrosion damage, structural defects, and certification issues represent the most common problems discovered during spreader bar inspections. Proper storage protocols prevent these issues while maintaining equipment readiness and compliance standards.

Effective storage practices ensure spreader bars remain inspection-ready and operationally safe, connecting to the comprehensive maintenance and documentation requirements covered in equipment lifecycle management.

How Do Inspection and Maintenance Impact the Safe Handling of Spreader Bars?

Inspection and maintenance directly impact spreader bar safety by preventing equipment failure and ensuring compliance with ASME B30.20 standards. Regular inspection identifies structural defects before they cause accidents, while proper maintenance extends equipment life and maintains load-bearing capacity. A 2019 OSHA analysis found that 67% of crane and rigging violations involved inspection-related failures across industrial facilities nationwide.

This section covers essential inspection protocols before and after transport or storage, documentation requirements for compliance, and criteria for determining when equipment requires repair or retirement.

What Inspection Checks Are Needed Before and After Transport or Storage?

Pre-transport and post-storage inspection checks include examining the main body for wear, distortion, damage, nicks, gouges, cracks, and corrosion that compromise load-bearing capacity. Focus inspection on suspension points and attachment points using identical criteria, as these areas experience concentrated stress during lifting operations.

Essential inspection elements include:

- Structural integrity assessment for cracks, deformation, or corrosion

- Weld examination using visual and non-destructive testing methods for cracking or fatigue

- Hardware inspection of shackles, hooks, and connection components for wear or damage

- Marking verification ensuring manufacturer’s name, serial number, and rated load remain present and legible

- Connection point analysis checking for excessive wear that creates failure pathways

Connection points require special attention because they transfer concentrated loads during lifting operations and represent common failure points in spreader bar systems.

How Should You Document Spreader Bar Inspections and Maintenance?

Documentation requirements for spreader bar inspections and maintenance follow ASME and OSHA standards for equipment compliance. Inspection records must be maintained for all frequent and periodic inspections, documenting the inspector’s findings, date of inspection, and any corrective actions taken.

Required documentation includes:

- Inspection records with inspector findings, dates, and corrective actions

- Proof testing results including test loads applied, test duration, and qualified personnel certification

- Maintenance logs documenting all activities, findings, and corrective actions for ASME and OSHA compliance

- Equipment marking verification confirming rated load capacity, manufacturer’s name, and serial number remain legible

According to ASME B30.20 standards, rated load capacity must be permanently displayed in legible characters, while manufacturer’s name and serial number enable identification and tracking throughout the device’s service life.

When Is It Time to Repair or Retire a Spreader Bar?

Repair or retirement decisions for spreader bars depend on structural integrity assessment and compliance with safety standards. Any crack, regardless of size, compromises structural integrity and creates failure risk during operation, requiring immediate equipment removal from service.

Critical retirement criteria include:

- Structural damage: Cracks in steel, broken welds, or deformation indicating overloading

- Component failure: Bending, twisting, or steel tube deformation from impact or overloading

- Load capacity compromise: Damage affecting load-bearing capacity or buckling potential

- OSHA compliance: Defective rigging equipment must be removed from service immediately

Long spreader bars may fail through buckling before reaching material yield limits, particularly when top sling angles create high compression loads. Re-testing may be required after repairs or modifications that affect load-bearing capacity to ensure continued safe operation.

Regular inspection and maintenance create a foundation for safe spreader bar handling, while proper documentation ensures regulatory compliance and operational accountability throughout equipment service life.

How Should You Approach Spreader Bar Transport and Storage with Support from Tway Lifting?

Partnering with an experienced rental provider streamlines compliance and enhances safety protocols for spreader bar transport and storage operations. This section covers how Tway Lifting’s rental services simplify regulatory requirements and reviews the essential safety practices for effective spreader bar handling.

Can Tway Lifting Help With Safe Transport and Storage of Spreader Bars?

Tway Lifting can help with safe transport and storage of spreader bars through comprehensive rental services backed by 70+ years of ASME-compliant equipment manufacturing expertise. Each rental spreader bar undergoes rigorous certification processes including serialization, clear capacity markings, and current Certificates of Test with complete inspection records for regulatory compliance.

Fixed, adjustable, and modular spreader bar rentals receive hydraulic proof-load testing between 125%–200% of their rated capacity before deployment. Equipment undergoes re-inspection before every dispatch, ensuring each rental arrives certified, documented, and ready for immediate use with full regulatory compliance and operational confidence.

Tway Lifting’s rental program combines certified inspection, proof-load testing, and complete documentation to simplify OSHA and ASME compliance requirements. Partnering with this ISO-certified rental provider ensures every spreader bar meets the highest safety and compliance standards while providing certified inspection services for existing lifting equipment.

This comprehensive approach eliminates compliance uncertainties and reduces liability risks during critical lifting operations.

What Are the Key Takeaways About How to Transport and Store Spreader Bars Safely We Covered?

The key takeaways about how to transport and store spreader bars safely include adherence to established safety protocols, regulatory compliance, and proven cost-saving benefits. Research from the National Institute for Occupational Safety and Health shows that 89% of crane-related fatalities could be prevented through adherence to established safety protocols.

From 2011 to 2017, the Census of Fatal Occupational Injuries (CFOI) reported 297 total crane-related deaths, an average of 42 per year. The National Safety Council estimates the average cost of a workplace injury to be around $43,000, and for a fatality, that number skyrockets to over $1.46 million.

Essential safety requirements include:

- OSHA requires 125% proof testing for all custom-designed lifting accessories before initial use

- ASME B30.20-2025 serves as the definitive safety standard for below-the-hook lifting devices including spreader bars

- Proper environmental controls maintain relative humidity below 60% during storage

- Regular inspection protocols prevent structural failures and ensure ongoing compliance

For every $1 spent on workplace safety, companies save as much as $6 in direct and indirect costs. Proven mistake-prevention strategies eliminate 94% of rigging-related accidents and reduce crane incident rates by 87%.

Understanding and adhering to these standards protects workers, prevents equipment damage, and ensures operational efficiency while meeting legal requirements for safe lifting operations.